Electrode matched with Mg-Si-Sn-based thermoelectric element and connecting process thereof

A mg-si-sn, thermoelectric element technology, applied in the field of electrodes, can solve the problem of low performance of Si thermoelectric materials, and achieve the effects of avoiding micro-cracks, improving service life and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

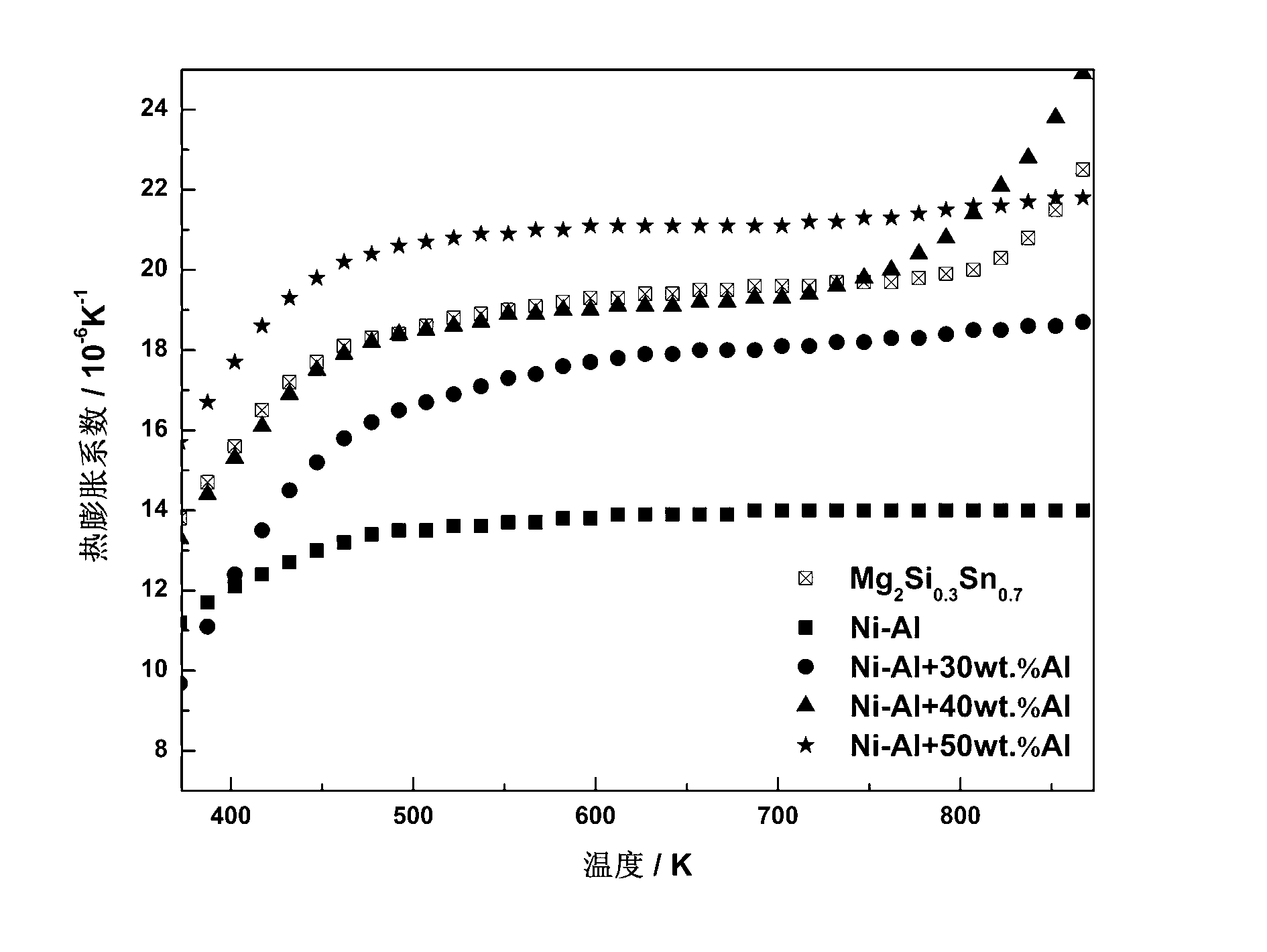

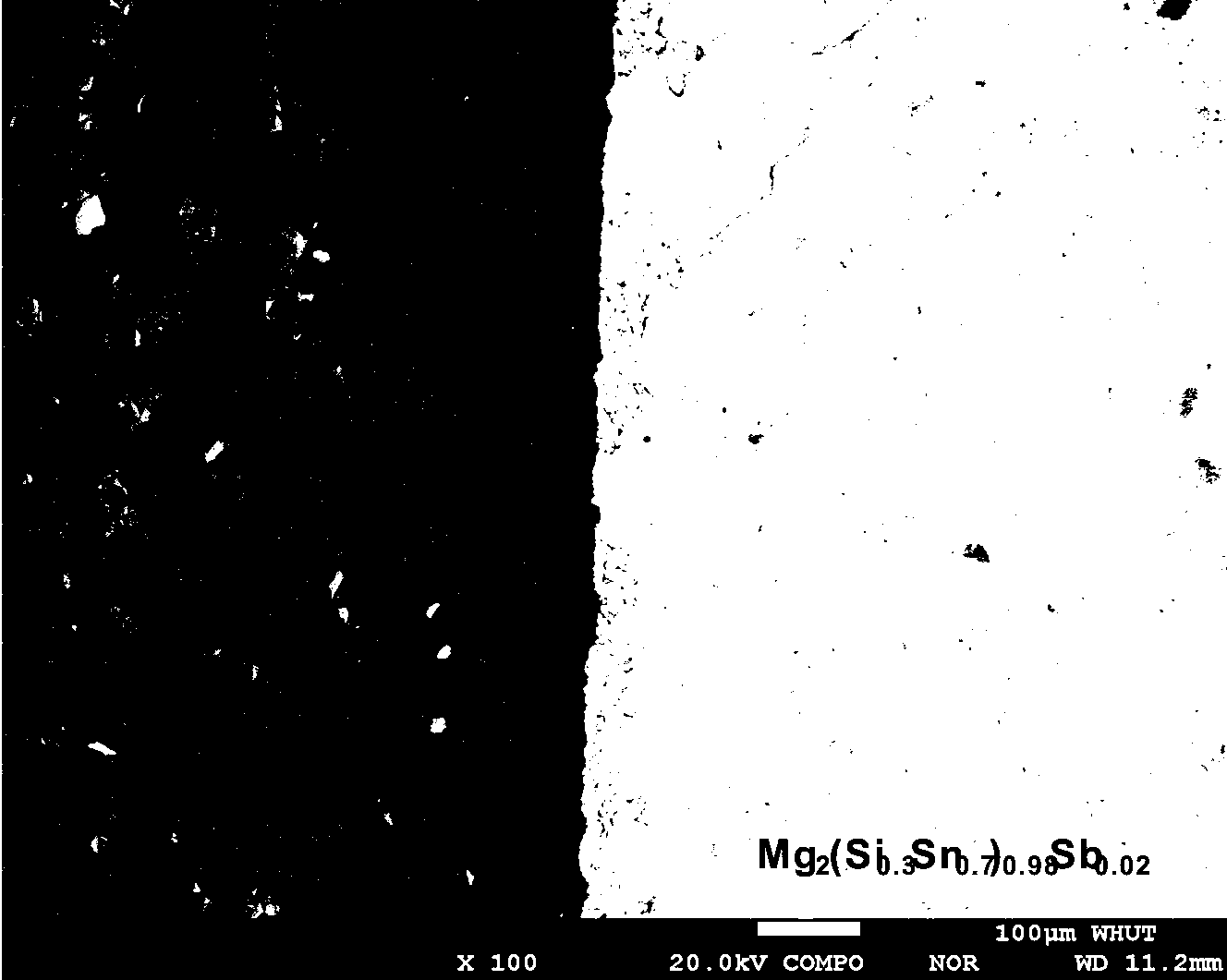

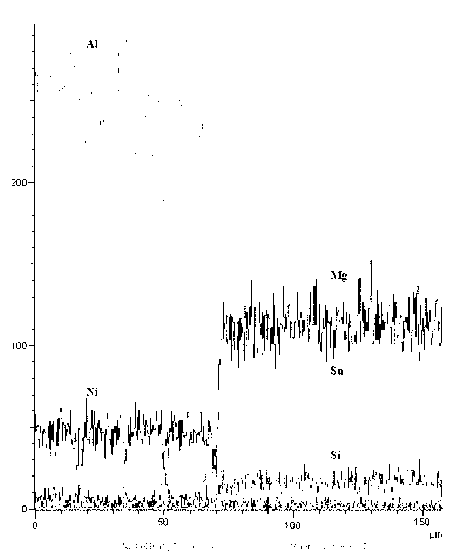

[0029] An electrode matched with a Mg-Si-Sn based thermoelectric element, which is composed of a mixture of Ni-Al alloy and metal element Al, wherein the mass percentage of metal element Al is 40%, and the balance is Ni-Al alloy , the mass percent content of Ni in the Ni-Al alloy is 47%, and the rest is Al.

[0030] The connection process between electrodes and thermoelectric elements of the present invention is connected by spark plasma sintering, and the specific process steps are:

[0031] 1) Take 3.0g of Mg-Si-Sn-based material powder prepared by solid-state reaction, and conduct the first step of spark plasma sintering in a graphite mold. During sintering, the vacuum degree is 25Pa, the sintering pressure is 30MPa, and the sintering temperature is 650℃. Obtain a dense Mg-Si-Sn block with a thickness of 5mm;

[0032] 2) The upper and lower surfaces of the dense Mg-Si-Sn block obtained in step 1) were polished with 400-grit sandpaper, and then ultrasonically treated for 10...

Embodiment 2

[0038] An electrode matched with a Mg-Si-Sn based thermoelectric element, which is composed of a mixture of Ni-Al alloy and metal element Al, wherein the mass percentage of metal element Al is 40%, and the balance is Ni-Al alloy , the mass percent content of Ni in the Ni-Al alloy is 47%, and the rest is Al.

[0039] The connection process between electrodes and thermoelectric elements of the present invention is connected by spark plasma sintering, and the specific process steps are:

[0040] 1) Take 3.0g of Mg-Si-Sn-based material powder prepared by solid-state reaction, and conduct the first step of spark plasma sintering in a graphite mold. The vacuum degree during sintering is 25Pa, the sintering pressure is 30MPa, and the sintering temperature is 670°C. Obtain a dense Mg-Si-Sn block with a thickness of 5mm;

[0041] 2) The upper and lower surfaces of the dense Mg-Si-Sn block obtained in step 1) were polished with 320-grit sandpaper, and then ultrasonically treated for 10...

Embodiment 3

[0047] An electrode matched with a Mg-Si-Sn based thermoelectric element, which is composed of a mixture of Ni-Al alloy and metal element Al, wherein the mass percentage of metal element Al is 40%, and the balance is Ni-Al alloy , the mass percent content of Ni in the Ni-Al alloy is 47%, and the rest is Al.

[0048] The connection process between electrodes and thermoelectric elements of the present invention is connected by spark plasma sintering, and the specific process steps are:

[0049] 1) Take 3.0g of Mg-Si-Sn-based material powder prepared by solid-state reaction, and conduct the first step of spark plasma sintering in a graphite mold. During sintering, the vacuum degree is 25Pa, the sintering pressure is 30MPa, and the sintering temperature is 700°C. Obtain a dense Mg-Si-Sn block with a thickness of 5mm;

[0050] 2) The upper and lower surfaces of the dense Mg-Si-Sn block obtained in step 1) were polished with 400-grit sandpaper, and then ultrasonically treated for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com