Electric connector and electric connector component

A technology of electrical connectors and components, applied in contact parts, fixed/insulated contact components, bases/shells, etc., can solve the problem that the volume of electrical connectors cannot be compressed, increasing the difficulty of assembling plug terminals, reducing the production efficiency of electrical connectors, etc. problem, achieve the effect of reducing the number of components, simplifying the structure, and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

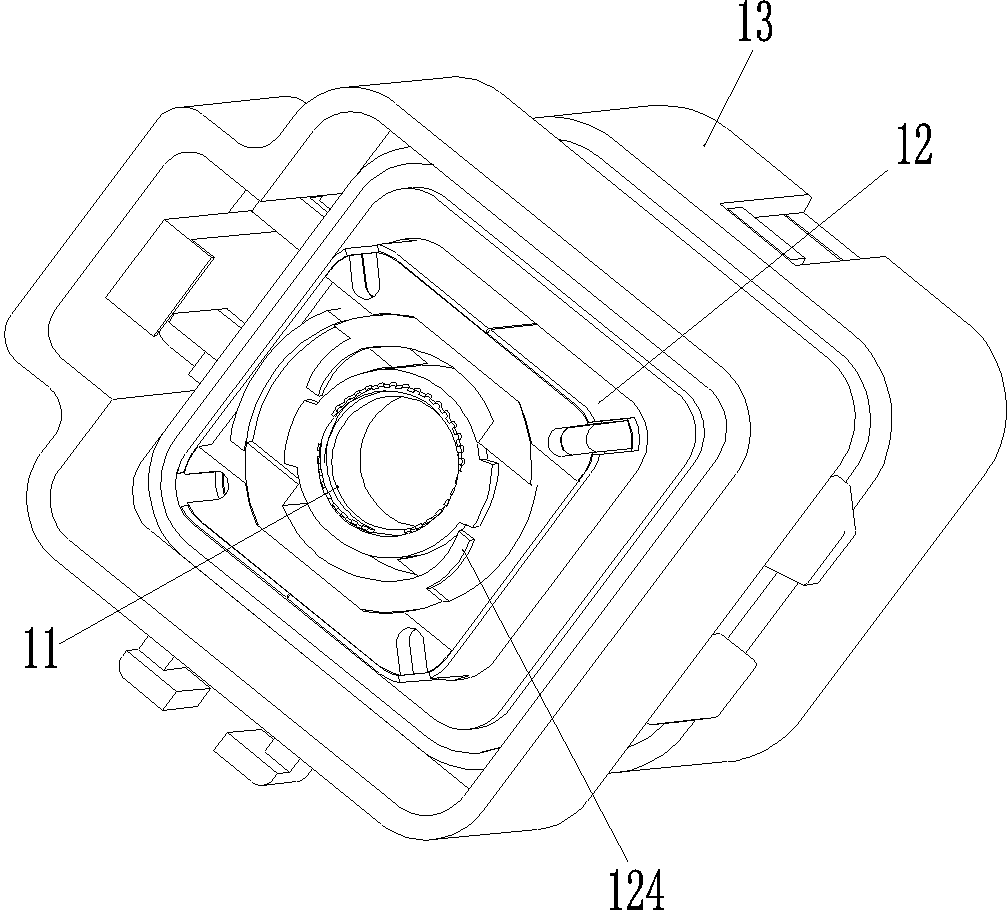

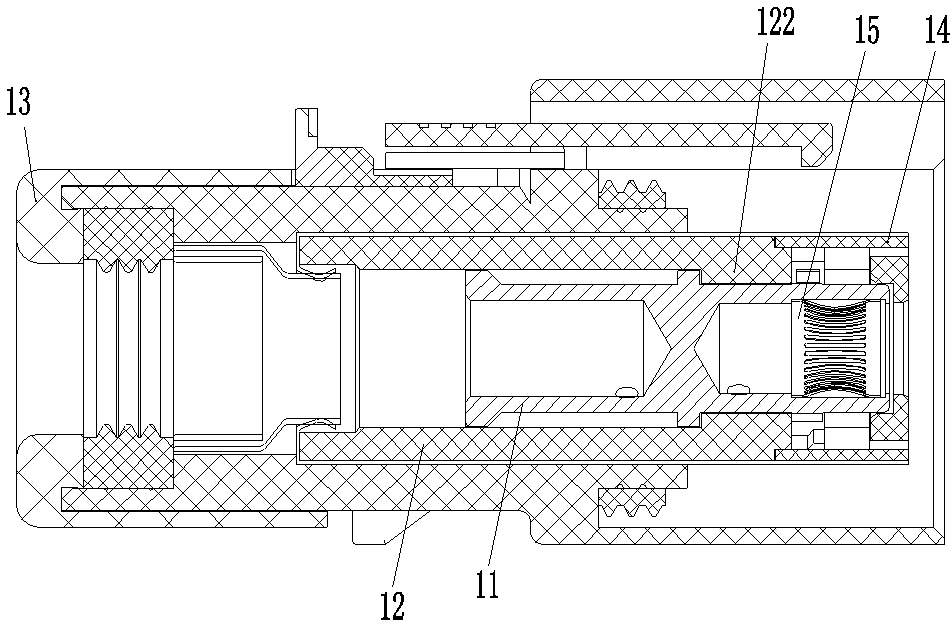

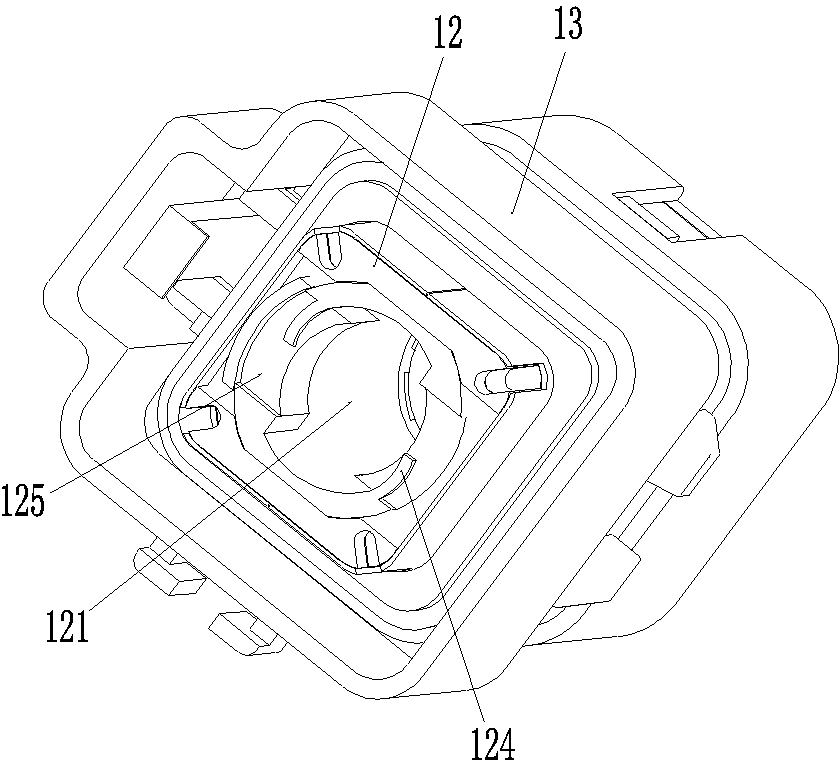

[0025] An embodiment of an electrical connector such as Figure 1-5 As shown, the electrical connector has a front end as a plug-in terminal, and includes a housing and a plug-in terminal 11 . The housing includes an inner housing 12 and an outer housing 13. The inner housing 12 is coaxially fixed and inserted in the outer housing 13. In addition, the inner housing 12 is provided with a terminal installation hole 121, and the hole wall of the terminal installation hole 121 There is a retaining ring 122 on it, and the retaining ring 122 protrudes toward the interior of the terminal installation hole 121 and has a through groove 123 through the front and back. In addition, the terminal installation hole 121 is also provided with a ratchet 124 and a stopper opposite to the ratchet 124. structure, the pawl 124 and the blocking structure are located in front of the retaining ring 122, and a bayonet structure is formed between the pawl 124 and the corresponding blocking structure to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com