Grid connecting system of permanent magnet synchronous wind driven generator

A wind turbine, permanent magnet synchronous technology, applied in wind power generation, control/regulation systems, electrical components, etc., can solve problems such as low grid-connected voltage, reduce heat loss, and enhance low-voltage operation capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

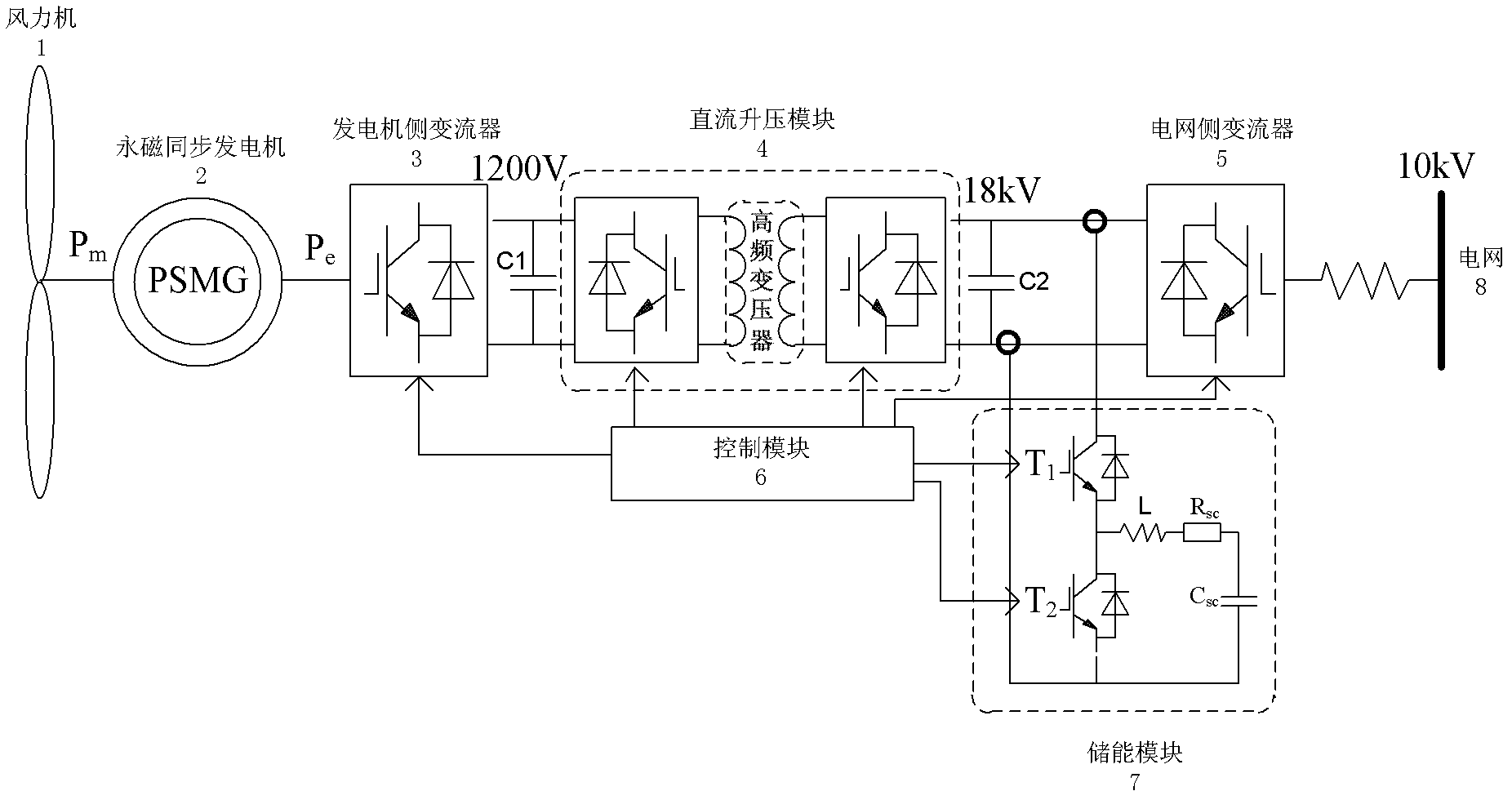

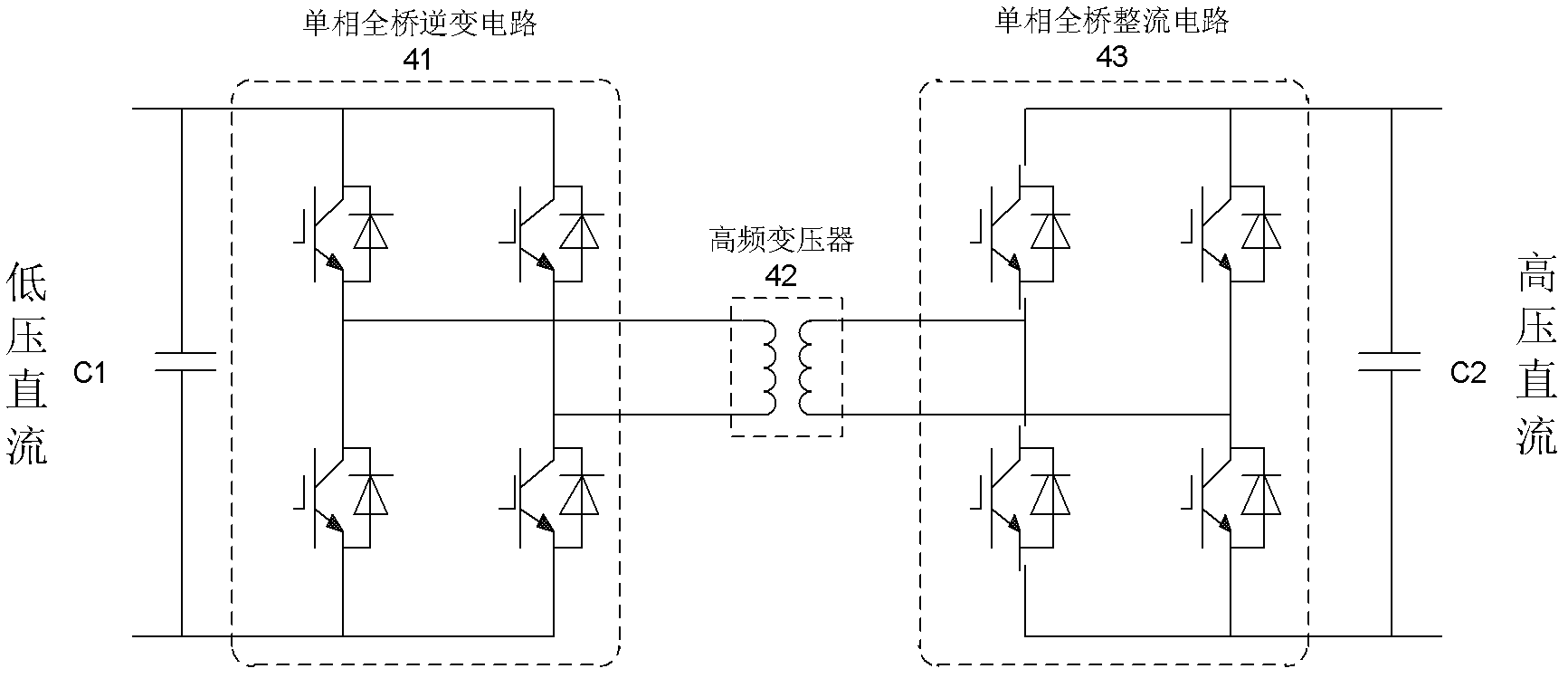

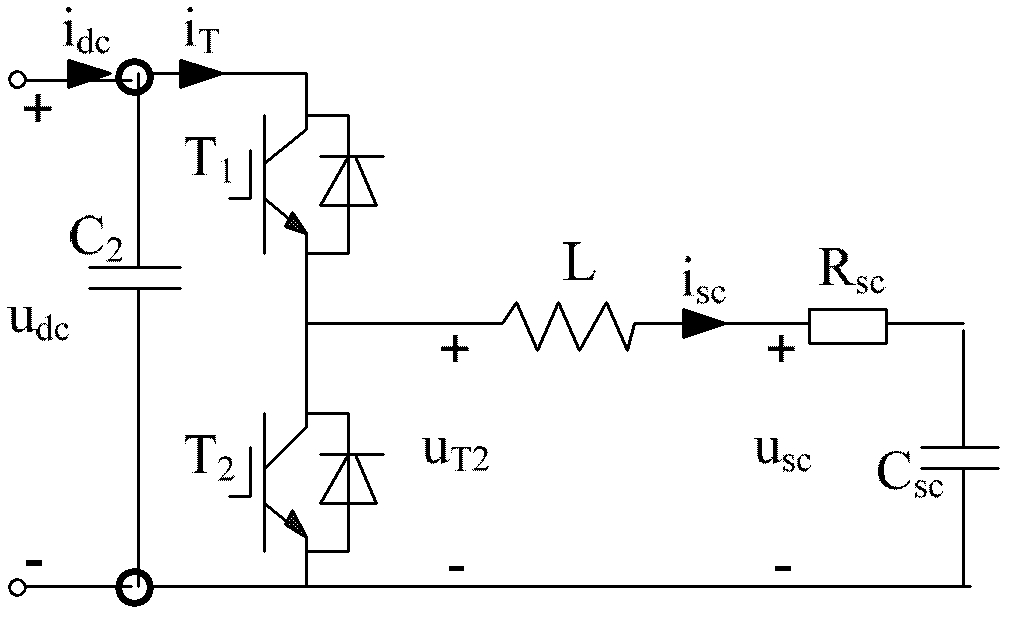

[0025] Such as figure 1 As shown, a permanent magnet synchronous wind generator grid-connected system includes a wind turbine 1, a permanent magnet synchronous generator 2, a generator-side converter 3, a DC boost module 4, a grid-side converter 5, and a control module 6 and energy storage module 7. The wind turbine 1, the permanent magnet synchronous motor 2, the generator-side converter 3, the DC boost module 4 and the grid-side converter 5 are sequentially connected to the power grid 8, and the generator-side converter 3 and the DC boost module 4 is connected in parallel with a first capacitor C1, a second capacitor C2 is connected in parallel between the DC boost module 4 and the grid-side converter 5, and the energy storage module 7 is connected in parallel between the second capacitor C2 and the grid-side converter 5 , the control module 6 is respectively connected with the generator-side converter 3 , the DC step-up module 4 , the grid-side converter 5 and the energy s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com