Asynchronous starting permanent magnet synchronous motor rotor based on permanent magnets with different residual magnetic densities

A permanent magnet synchronous and asynchronous starting technology, which is applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problems of increased torque fluctuation, increased vibration noise, increased harmonic loss, etc., to achieve Reduce the sine distortion rate, reduce the torque ripple, reduce the effect of vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

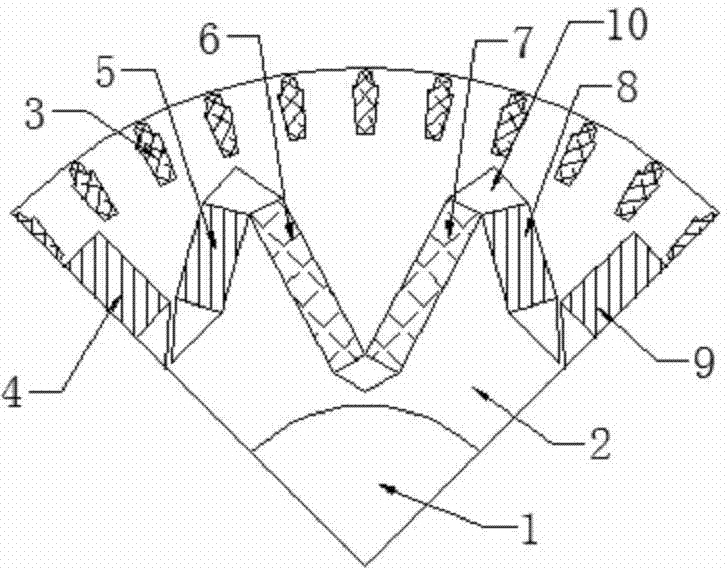

[0016] figure 1 It is a schematic diagram of the rotor structure under one magnetic pole in an embodiment of the present invention;

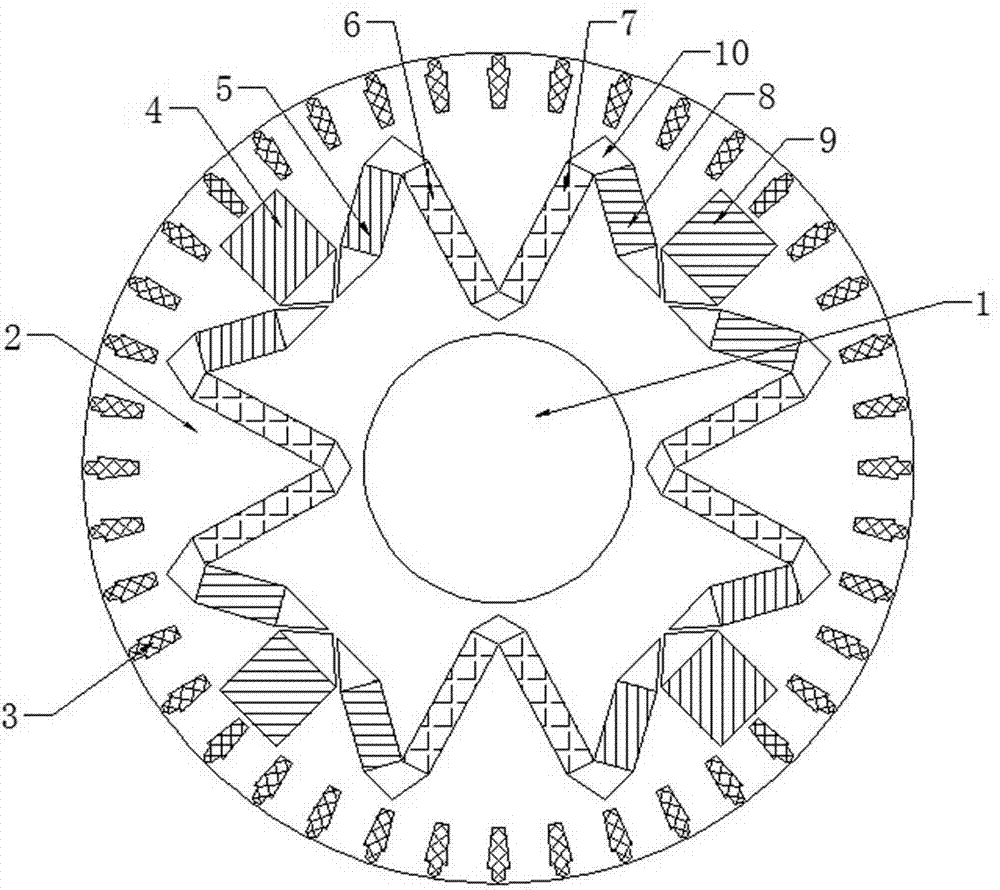

[0017] figure 2 It is a schematic diagram of the rotor structure of an embodiment of the present invention;

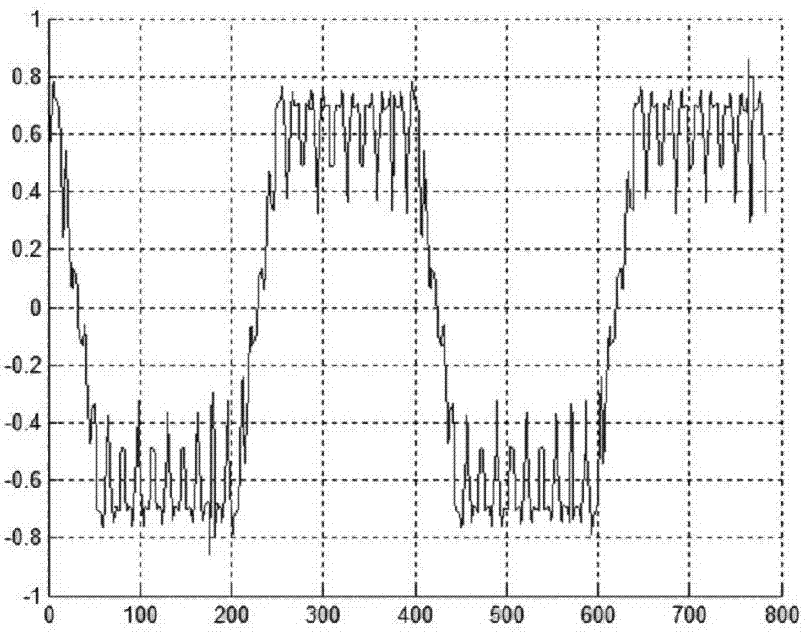

[0018] image 3 It is the no-load air-gap magnetic density waveform of a four-pole asynchronous start permanent magnet synchronous motor with a W-shaped permanent magnet structure and a rated power of NdFeB permanent magnet material of 37kW;

[0019] Figure 4 It is an asynchronous starting permanent magnet synchronous motor rotor air-gap flux density waveform diagram of an embodiment of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com