Commutator segment halved rotor and motor thereof

A commutator piece and rotor technology, applied in the direction of DC commutators, electrical components, electromechanical devices, etc., can solve the problems of hidden quality, unfavorable spot welding, narrow hook width, etc., and achieve the benefit of commutator spot welding , Reduce the failure rate of spot welding, and reduce the weight of copper used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Now in conjunction with accompanying drawing, the present invention will be further described:

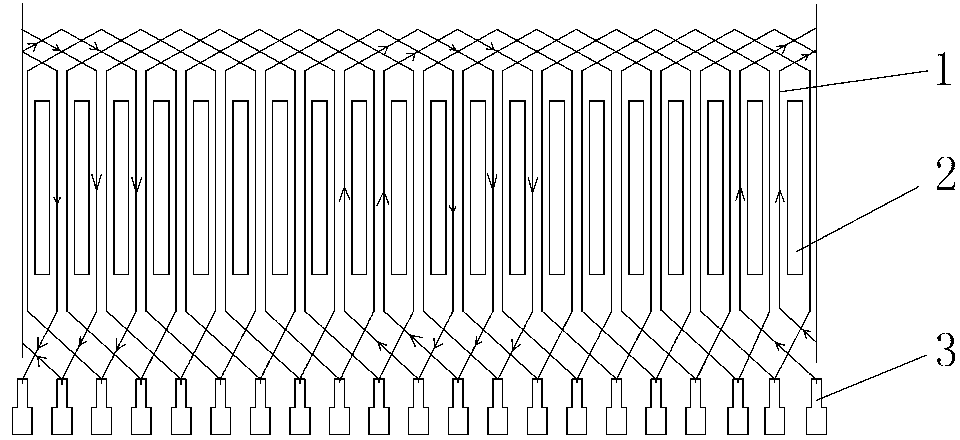

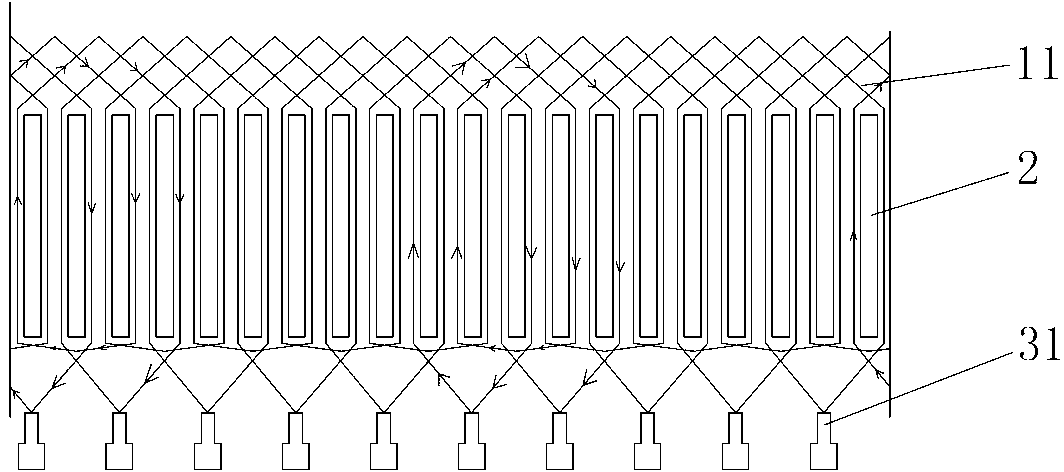

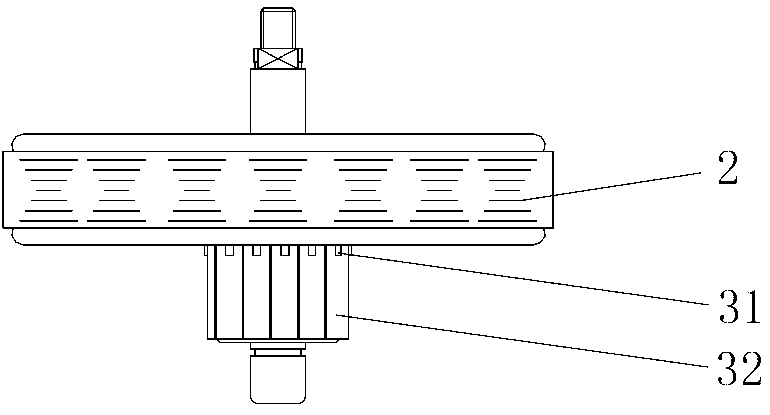

[0013] Such as figure 2 , image 3 As shown, a commutator segment halved rotor includes a rotating shaft, an iron core 2, a commutator, and a coil winding 11 wound with enameled wire. Each commutator segment 32 in the commutator is provided with a hook 31, and the coil winding 11 Wound on the iron core 2 , the number of commutation segments 32 is half of the number of the coil windings 11 , and the enameled wire is electrically connected at the hook 31 after every two coil windings 11 are wound.

[0014] A motor, including a motor casing including a stator and an end cover, a carbon brush assembly, and a commutator piece and a half-rotor.

[0015] The number of commutator segments of 20 sets of coil windings 11 is reduced by half, and the number of hooks 31 and commutator segments 32 is only 10. For other numbers of coil windings 11, the number of hooks 31 and commutator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com