Method for manufacturing oversize printed circuit board (PCB) back plate inner layer

A production method and super-sized technology, which is applied in the field of super-sized PCB backplane inner layer production, can solve problems such as short-circuit scrapping of the backplane inner layer, A/B deviation, etc., and achieve the effect of avoiding alignment deviation and accurate alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

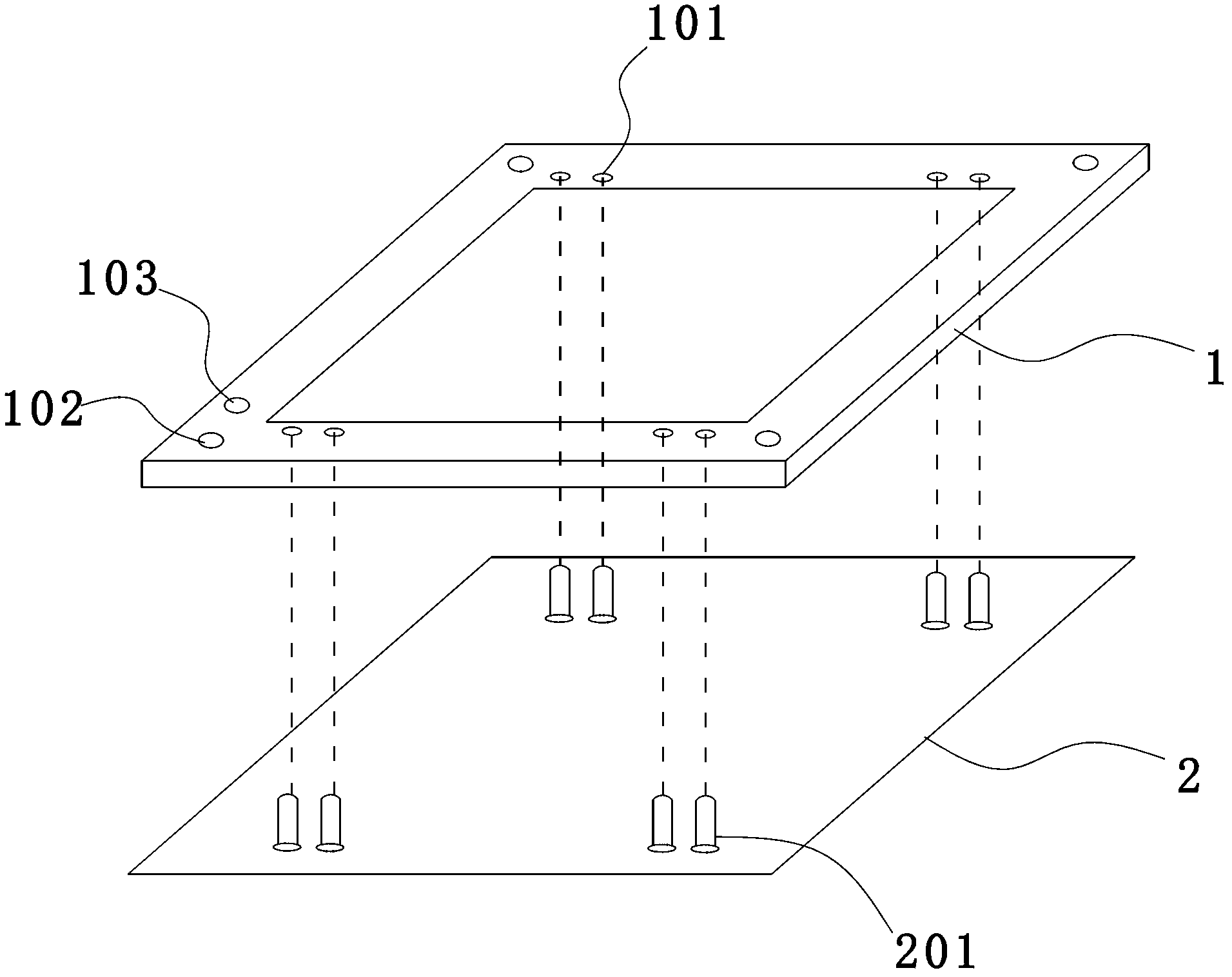

[0022] See figure 1 as shown, figure 1 It is a schematic diagram of the positioning state of the super-sized PCB backboard inner layer board and the film negative in the present invention. The present invention provides a method for manufacturing the inner layer of a super-sized PCB backplane, comprising steps:

[0023] S1. Cut the material to make the inner core board, and drill two PIN nail holes with a diameter of 2.1mm and one alignment inspection hole with a diameter of 3.175mm at the four corners of the inner core board;

[0024] First, cut the copper clad laminate, and make the inner core board 1 according to the normal method, and then design a special PIN drill strip for the board edge of the inner core board, because the size of the inner core board is larger , i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com