A kind of automatic porridge machine and preparation method of porridge

A production method and fully automatic technology, applied in food preparation, overflow prevention, cooking utensils, etc., can solve the problems of insufficient release of material nutrition, reduced material nutrition absorption, single processing process, etc., to facilitate observation and control, and speed up gelatinization. , the effect of improving digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

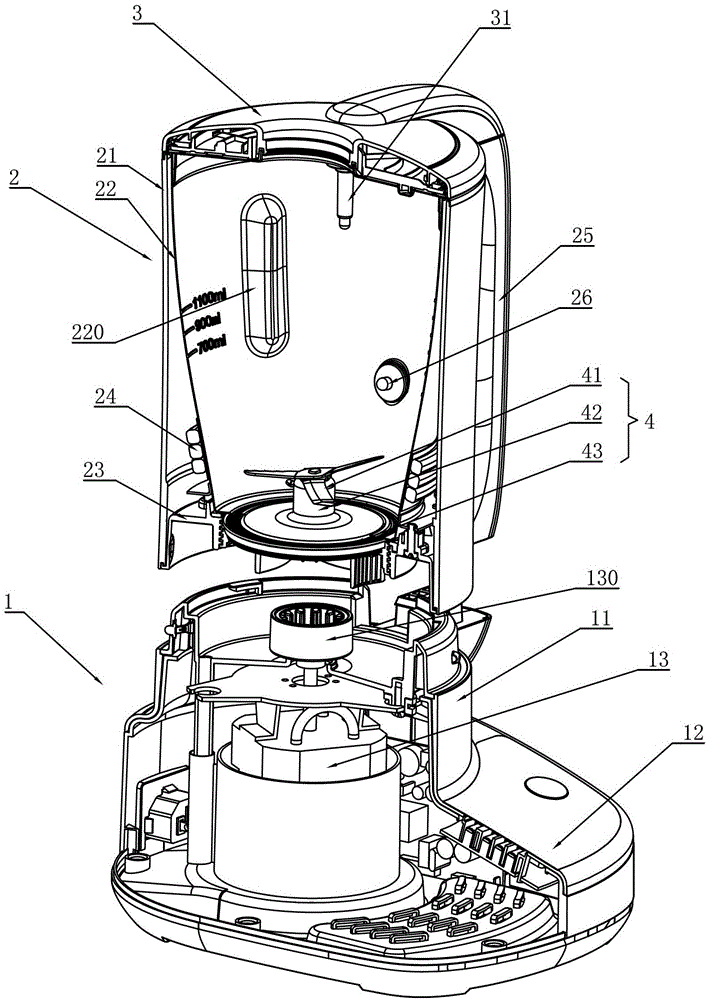

[0031] As the embodiment of a kind of fully automatic porridge machine described in the present invention, as figure 1 shown. The porridge machine includes a machine base 1 , a processing container 2 and an upper cover 3 . The processing container 2 is arranged on the machine base 1 , and the upper cover 3 covers the upper opening of the processing container 2 .

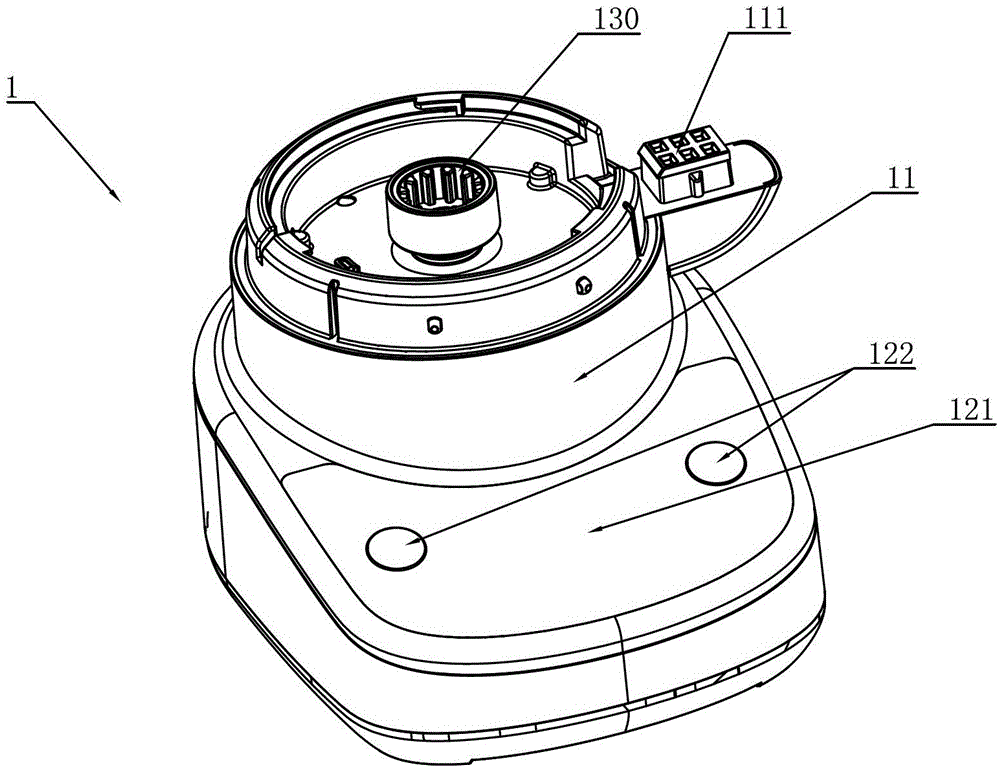

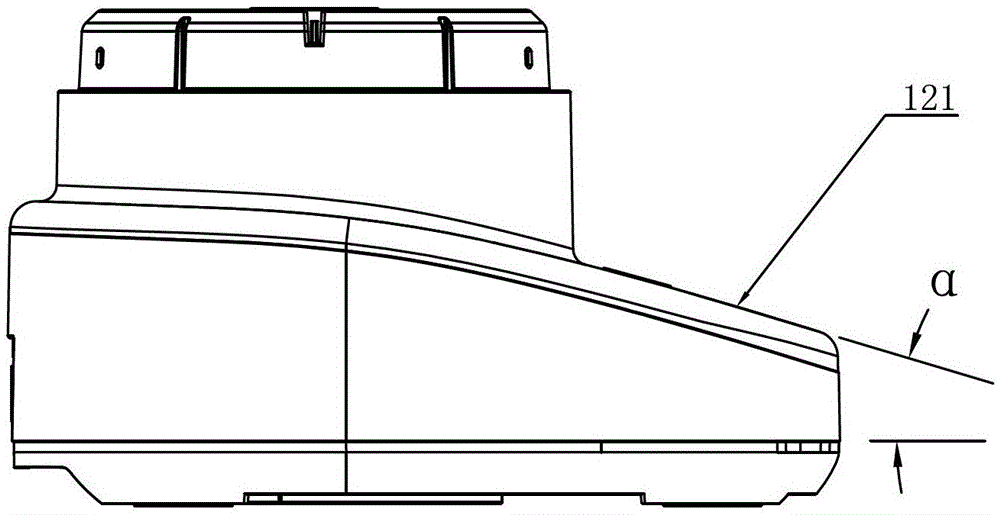

[0032] like Figure 1-3 As shown, the base 1 includes a power part 11 and an operation table 12, the operation table 12 is arranged on the side of the power part 11 and protrudes from the power part 11, and the operation table 12 is provided with an operation The panel 121 is provided with an operation button 122 on the operation panel 121, and the operation button 122 is a touch capacitive button. Correspondingly, a touch conductive spring is provided inside the operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com