Hose pipe of dust collector

A technology for vacuum cleaners and hoses, applied in the field of vacuum cleaners, can solve problems such as affecting the bending degree of hoses, and achieve the effects of improving energy efficiency, reducing noise and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

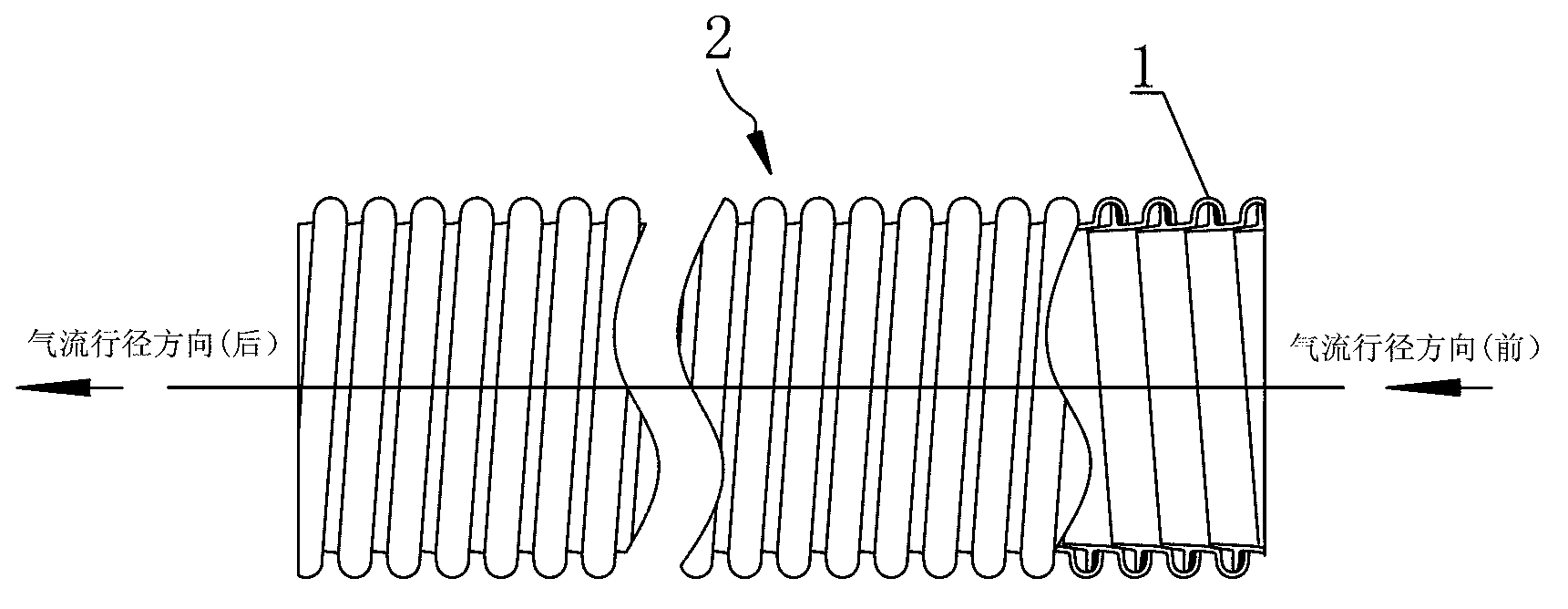

[0037] Such as figure 1 A hose for a vacuum cleaner, comprising a strip-shaped soft strip 1 extending along the length direction, the soft strip is an adhesive strip, and the strip-shaped soft strip 1 is spirally bonded to form a pipe body 2 . In this example:

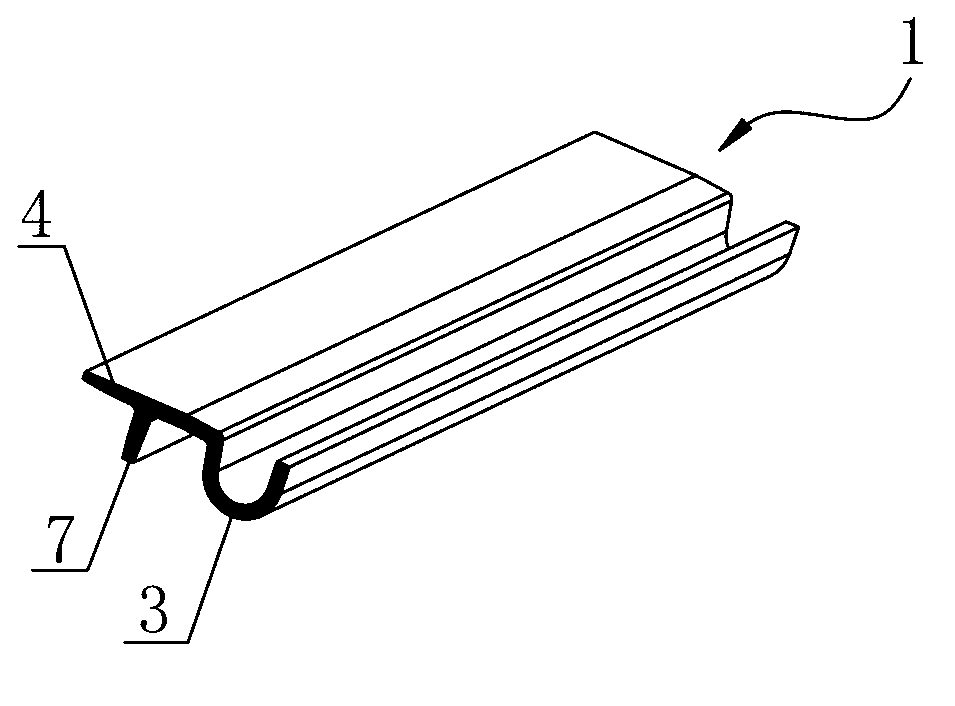

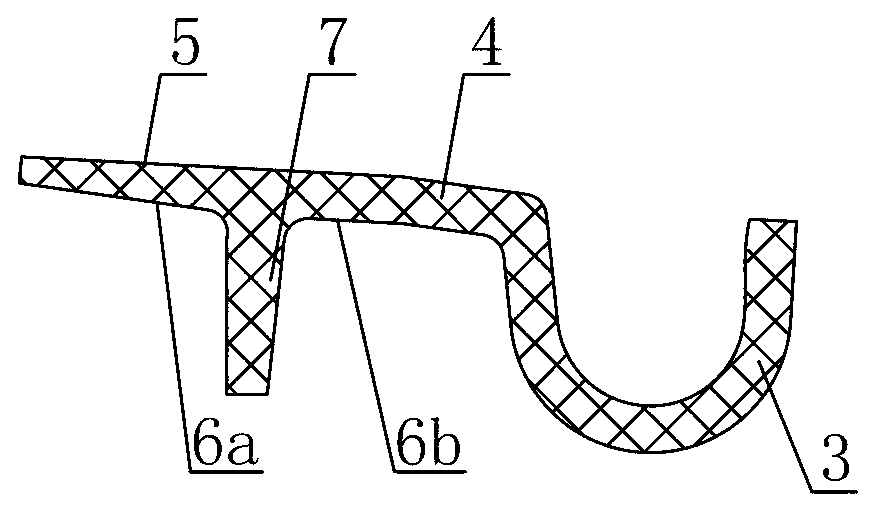

[0038] Such as figure 2 , 3 As shown: the strip-shaped flexible strip 1 includes a groove portion 3 in its width direction, an overlapping portion 4 connected to a port of the groove portion 3, the overlapping portion 4 has an inner surface 5, an outer surface 6, and the overlapping portion 4 has an inner surface 5 and an outer surface 6. The part 4 extends obliquely from one end of the groove part 3 to a direction away from one side thereof, and the outer surface 6 of the lap part 4 has a bonding part 7 extending outward, that is, the bonding part 7 connects the lap part The outer surface 6 of 4 is divided into two parts, and in this embodiment, the overlapping part 4, the groove part 3 and the bonding part ...

Embodiment 2

[0041] Such as Figure 5 A vacuum cleaner hose, comprising a strip-shaped soft strip 9 extending along the length direction, the soft strip is an adhesive strip, and the strip-shaped soft strip 9 is spirally bonded to form a pipe body 10 . In this example:

[0042] Such as Figure 6 , 7 Shown: the belt-shaped flexible strip 9 includes a groove portion 11 in its width direction, an overlapping portion 12 connected to a port of the groove portion 11, the overlapping portion 12 has an inner surface 13, an outer surface 14, and the overlapping The part 12 extends obliquely from one end of the groove part 11 towards and away from its two sides at the same time, that is, the groove part 11 divides the outer surface 14 of the lap part 12 into two; the lap part 12 moves away from the groove The outer surface 14 of the tail end of the overlapping portion 12 extending from one side of the portion 11 has a bonding portion 15 extending outward. In this embodiment, the overlapping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com