Patents

Literature

37results about How to "Less Cleaning Hassle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

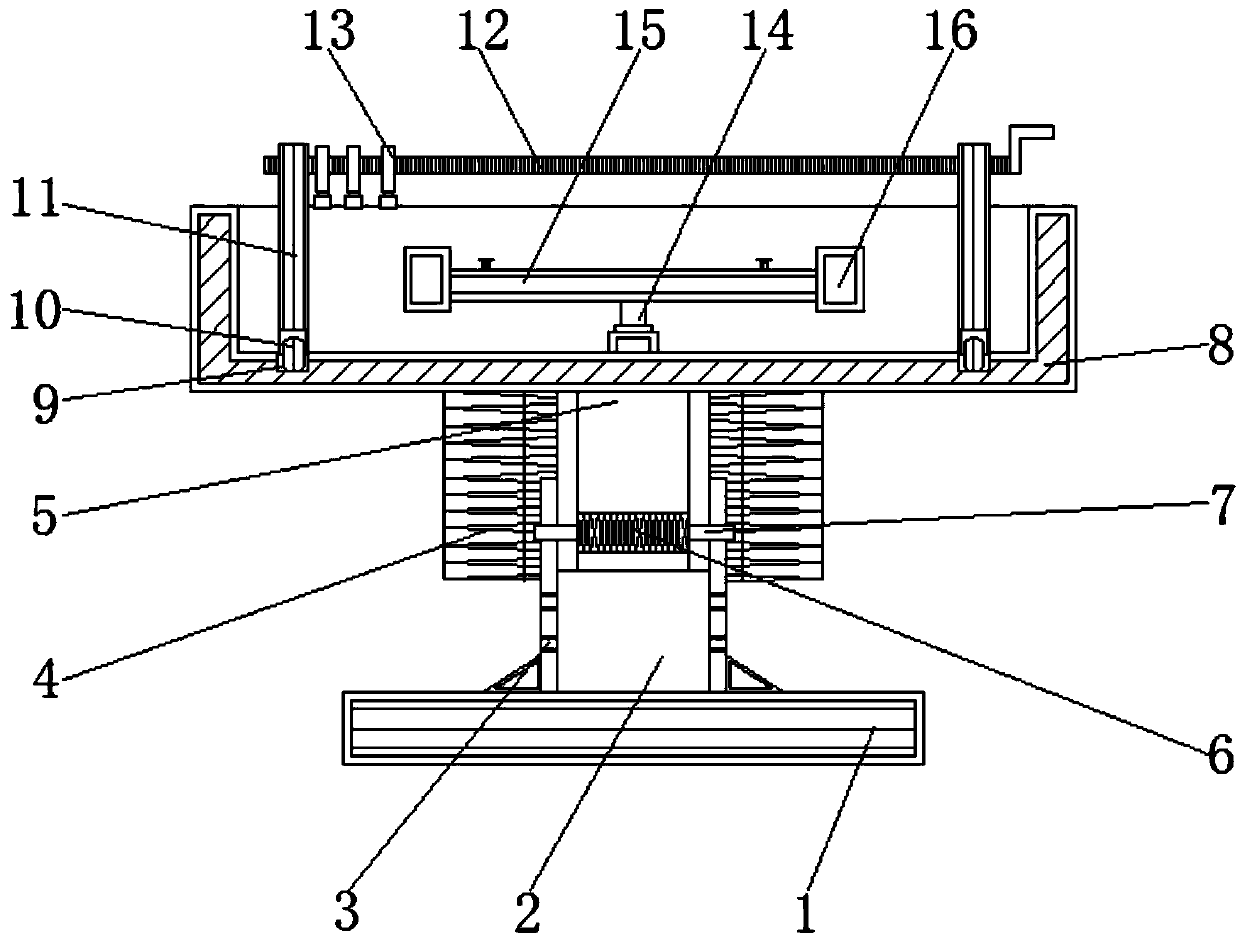

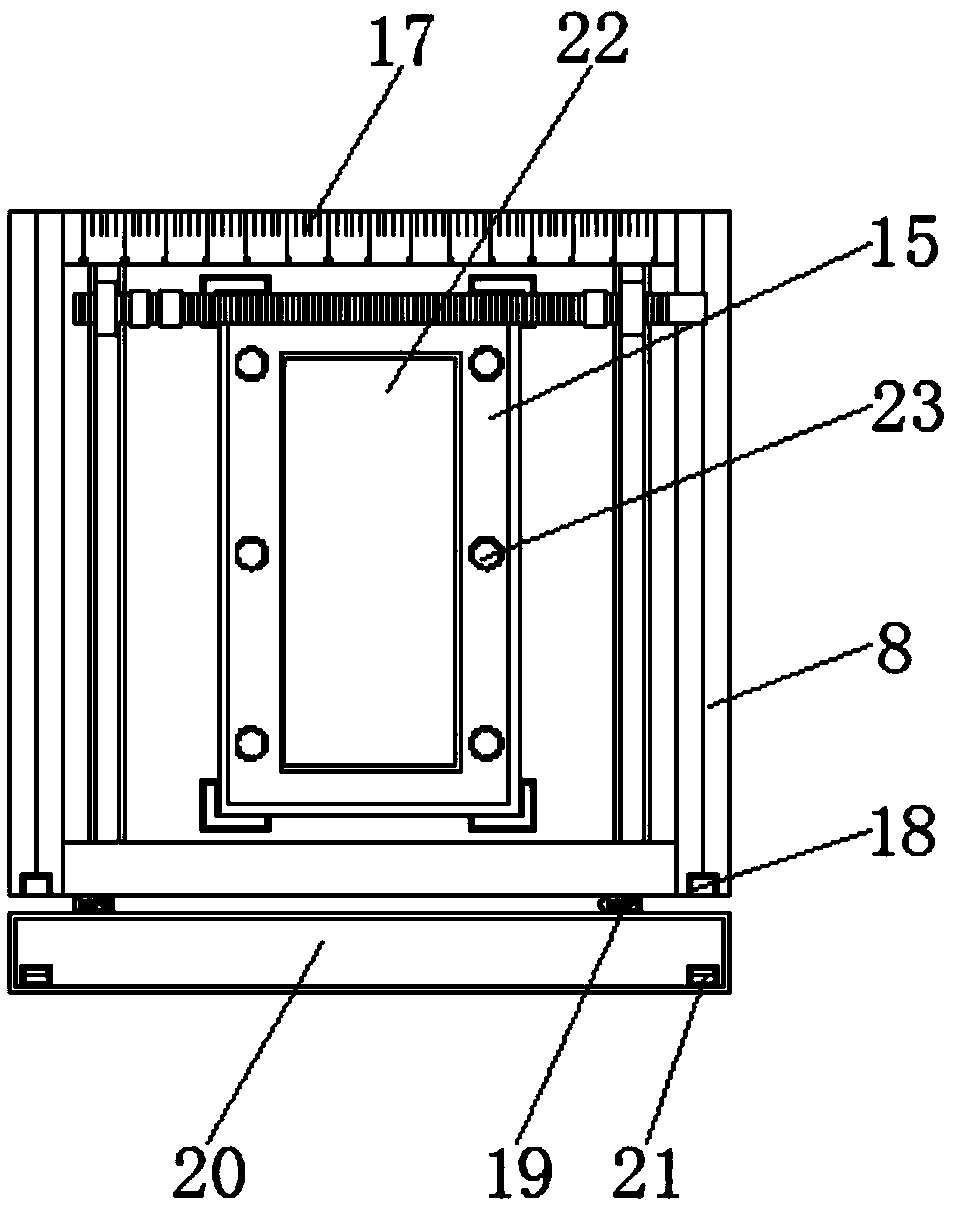

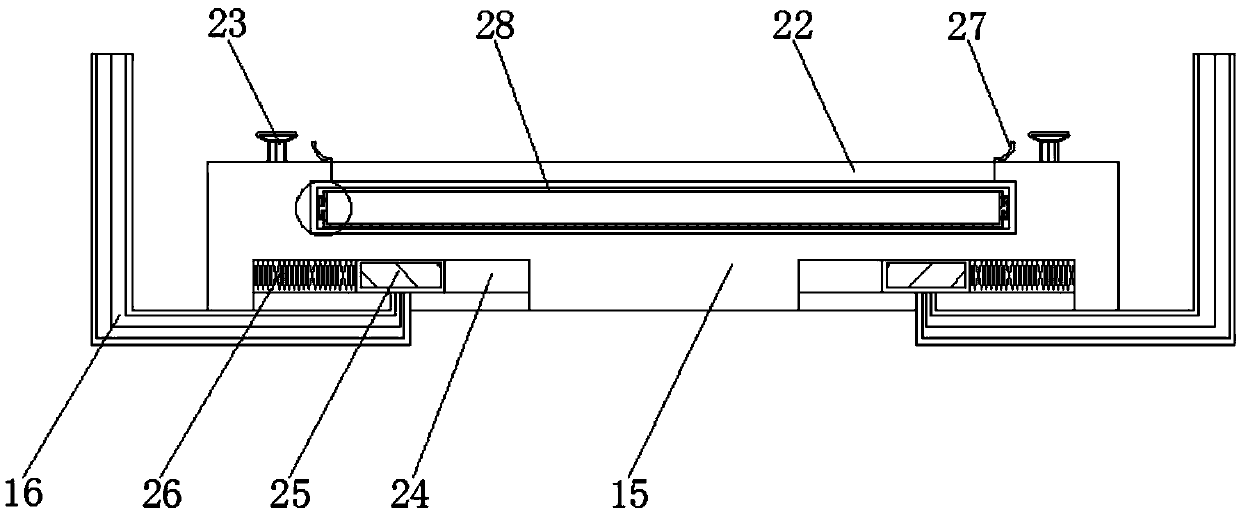

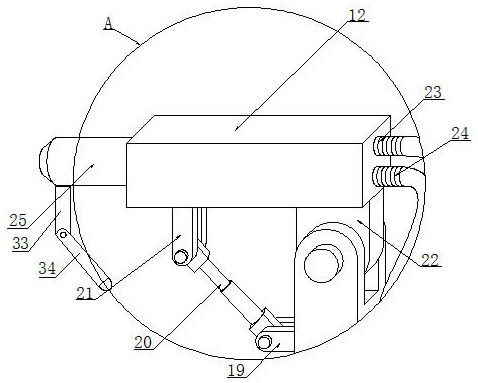

Stable cutting device with position limitation structure for tempered glass production

PendingCN108675625AImprove pass rateGuaranteed errorGlass severing apparatusCutting glassPulp and paper industry

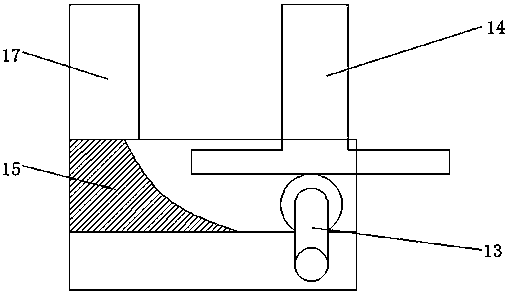

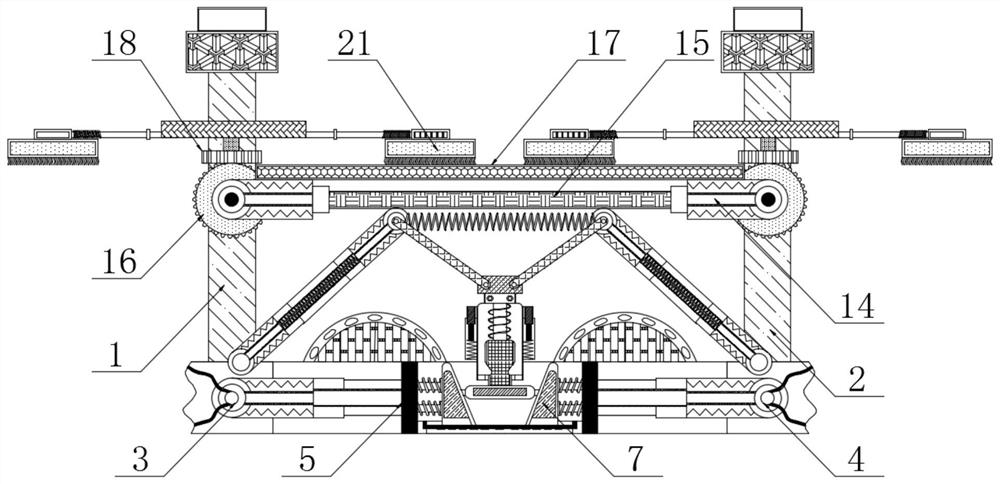

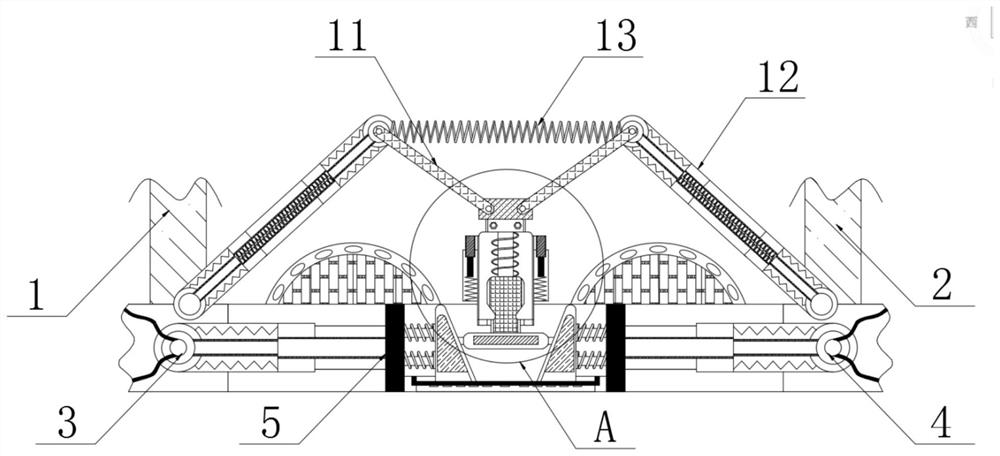

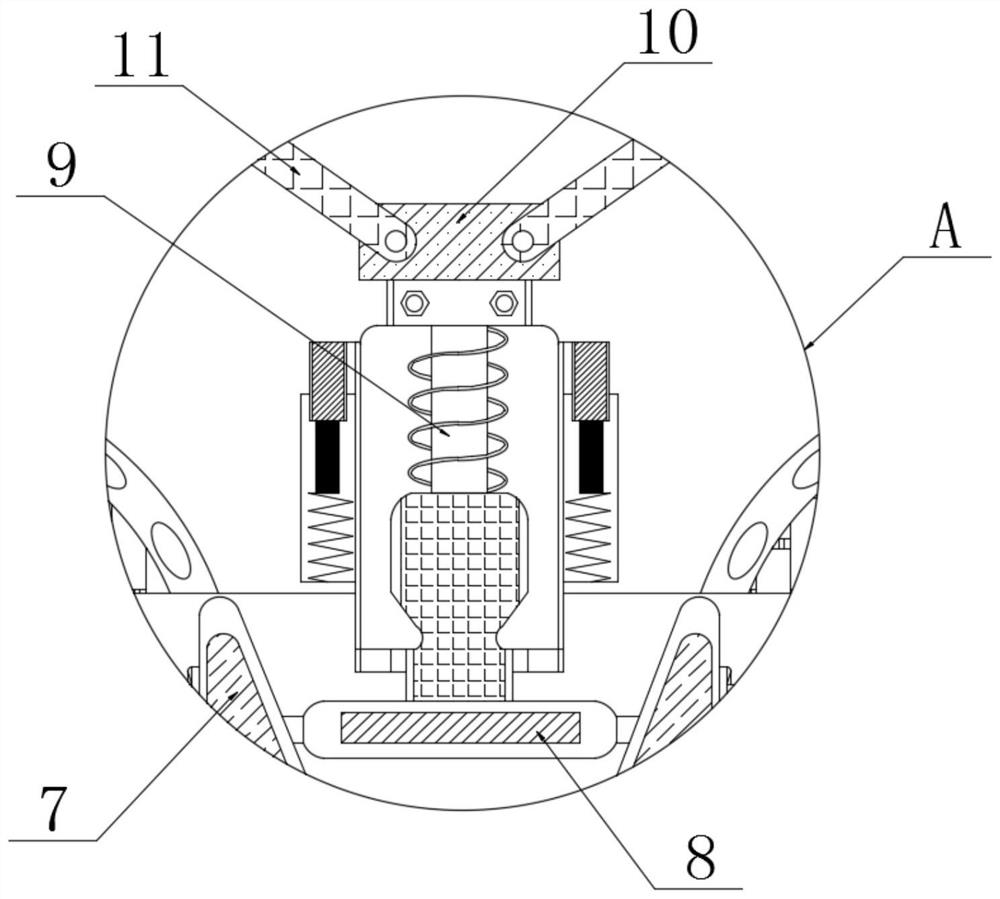

The invention relates to a stable cutting device with a position limitation structure for tempered glass production. The stable cutting device comprises a base plate, a movable rod, a guide plate, a fixed clamp block and a cutter head, wherein a lower support rod is fixed above the base plate. Through the arrangement of a position limiting rod, the glass can be subjected to position limiting treatment; the dimension deviation during the cutting is enabled to be avoided, so that the qualification rate of the cut glass can be improved; meanwhile, the connecting block and an invisible groove forman elastic structure through a third spring; the glass with the area being greater than a cutting table can be subjected to fixing treatment; the practicability of the device is improved; meanwhile,the duplex fixing treatment is performed on the glass through a suction disc; during the cutting, the glass cannot swing or deviate, so that the dimension error of the cut glass is enabled to be in areasonable range; through the arrangement of the upper support rod and the lower support rod, the cutting disc can be subjected to stable support treatment; through the arrangement of the through hole, the second spring and the clamp rod, the height sum of the lower support rod and the upper support rod can be regulated.

Owner:郭婷

Power transmitting tower with automatic cleaning function

InactiveCN108060819AGuarantee personal safetyExpand the scope of cleaningGeneral water supply conservationCleaning using toolsPulp and paper industryTower

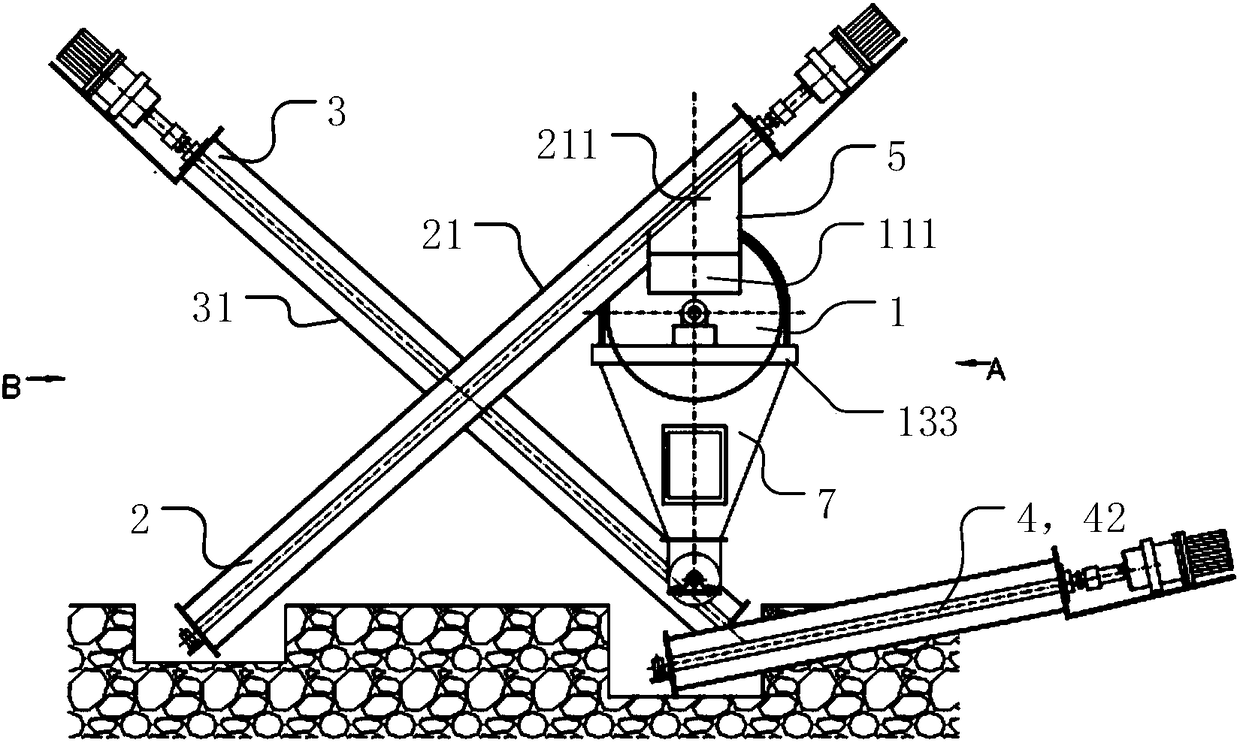

The invention discloses a power transmitting tower with an automatic cleaning function. The power transmitting tower comprises a tower body, a base, a cross rod and a binding post. The lower end of the tower body is fixedly connected with the base, and the upper end of the tower body is fixedly connected with the cross rod. A lead screw is arranged on the right side of the tower body, and the lower surface of the cross rod is fixedly connected with a first motor. The middle of the lead screw is sleeved with a sliding block, and the side wall of the sliding block is fixedly connected with a second motor. The shaft stretching end of the second motor is fixedly connected with a rotary shaft, and the lower end of the rotary shaft is sleeved with a gear. The middle of the tower body is sleevedwith an inner sleeve, and the inner sleeve is sleeved with an outer sleeve. The top end of the tower body is fixedly connected with a collecting box. The tower body can be cleared through the inner sleeve, dirt on the surface of the tower body is removed, the inner sleeve can vertically move along the tower body, and thus the sweeping range is enlarged; and rainwater can be collected through the collecting box to flush the tower body, thus the water resource is saved, the tower body is further cleaned, the trouble of tower cleaning through artificial climbing is avoided, and manpower is greatly saved accordingly.

Owner:山东博发智能科技有限公司

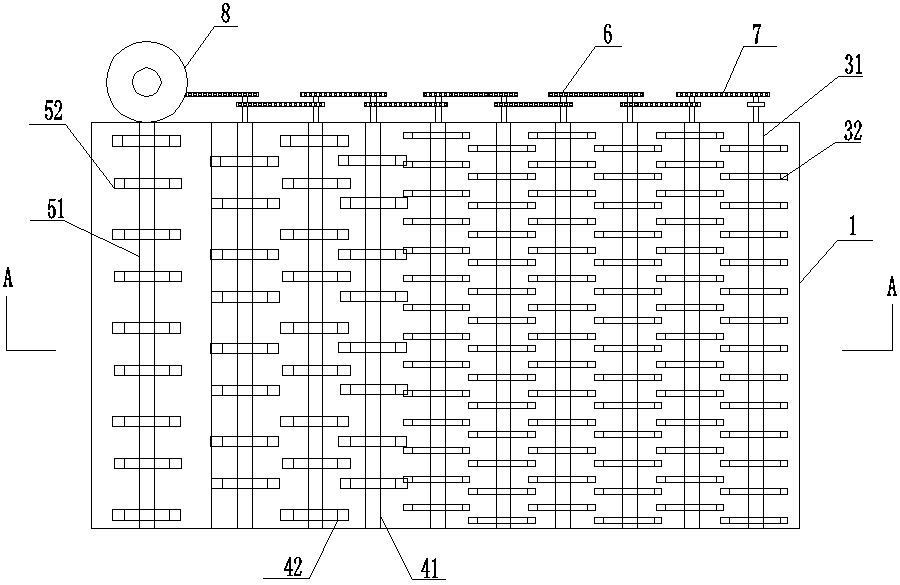

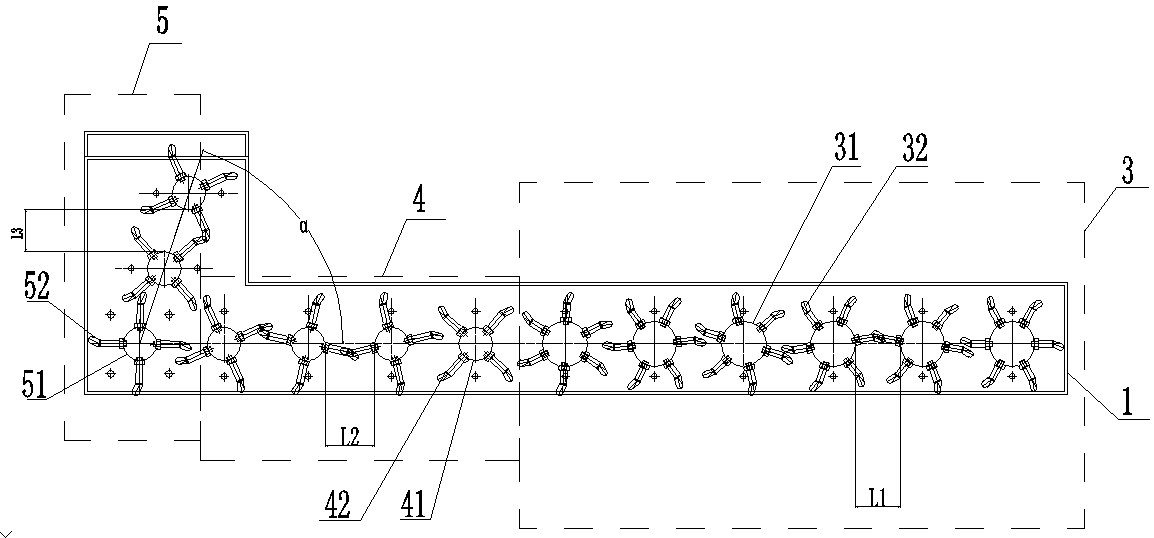

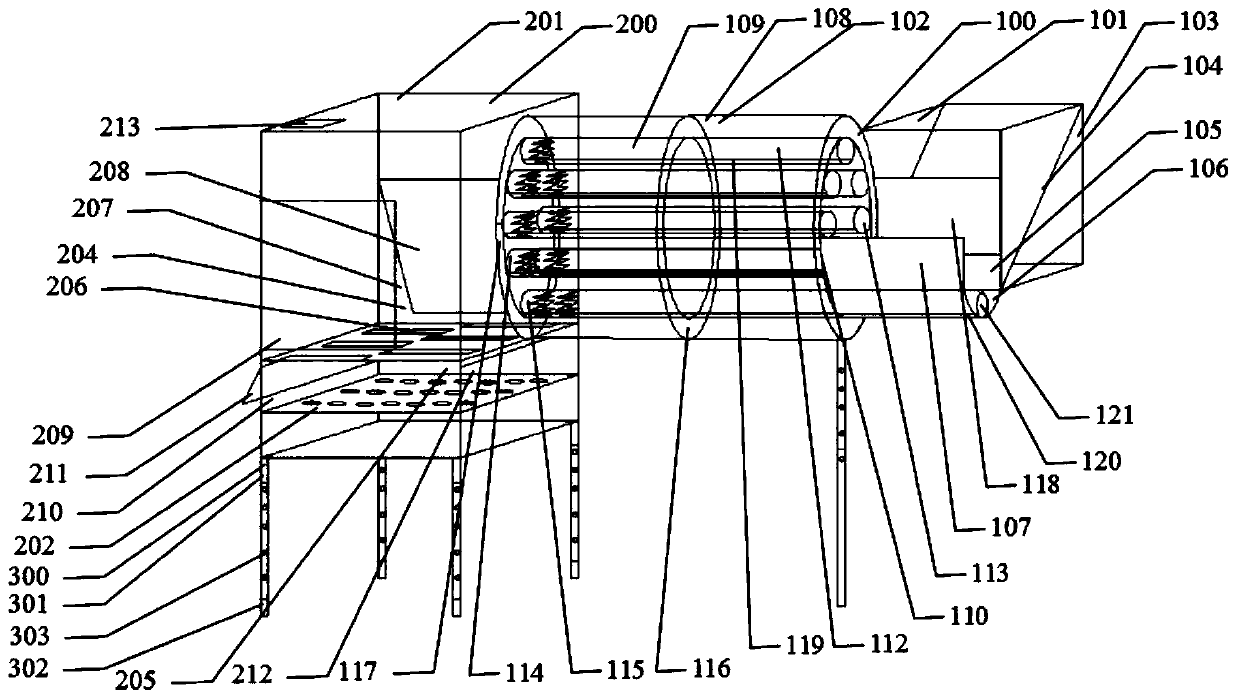

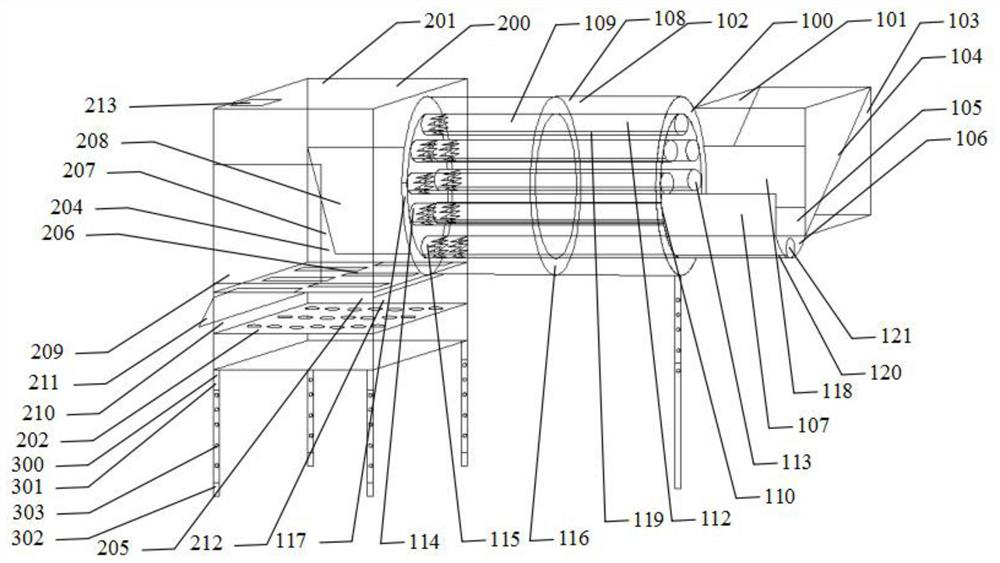

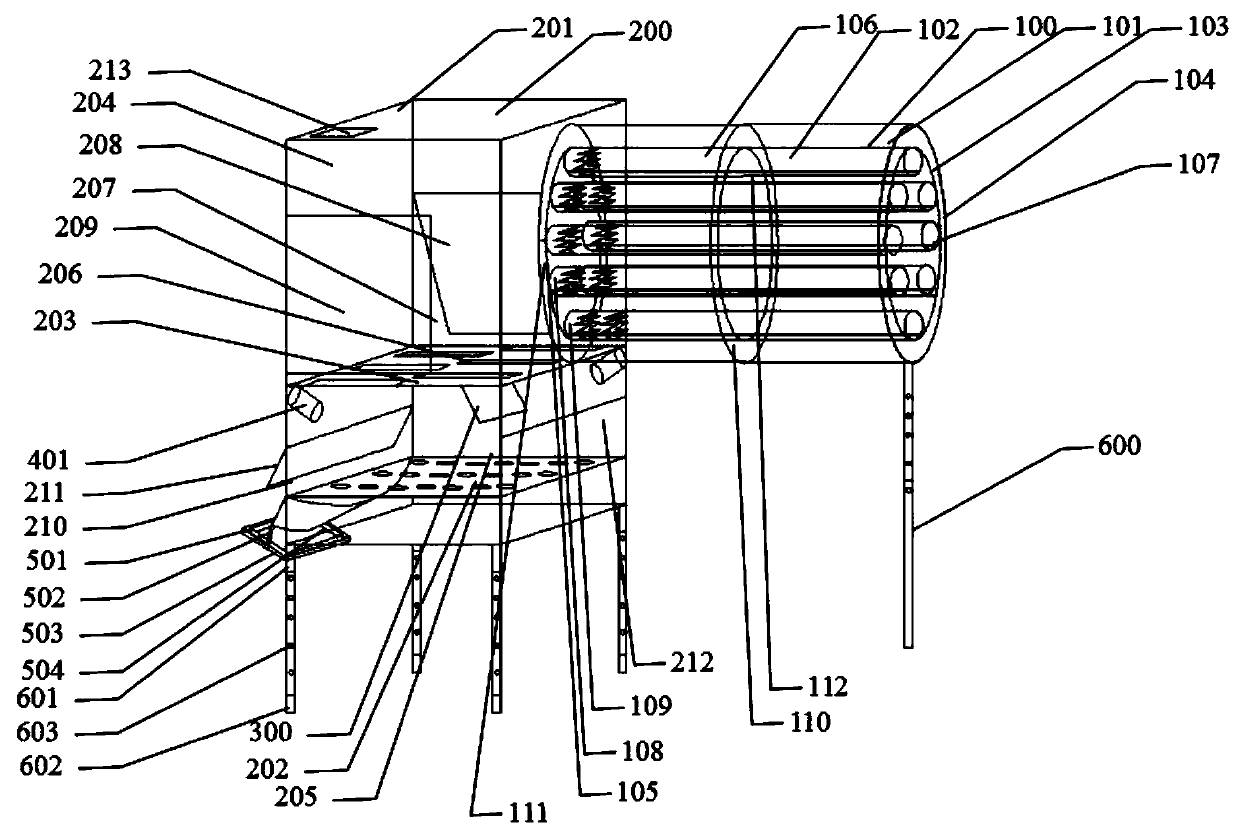

Cake tobacco sorting and loosening device

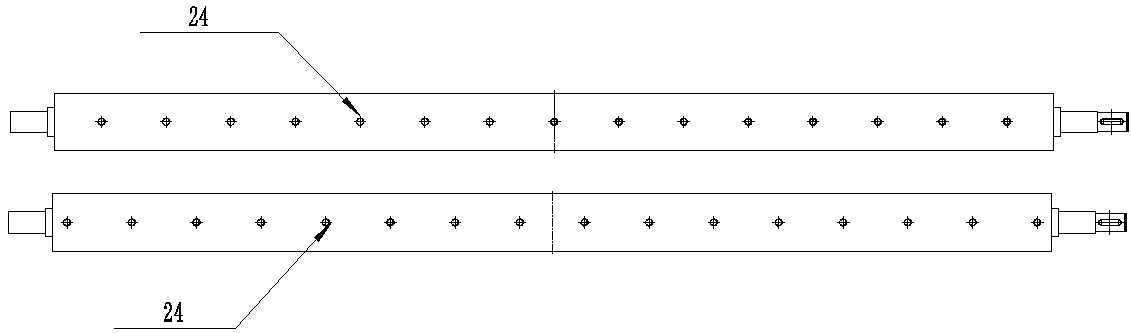

A cake tobacco sorting and loosening device comprises a frame. A conveyor for conveying sorted and loosened strips is arranged on the lower portion of the frame, a sorting area, a loosening area and aresistance area are sequentially arranged on the frame along the direction of materials, the sorting area and the loosening area are positioned on the same horizontal plane, the resistance area is higher than the loosening area, N1 sorting rollers are parallelly arranged in the sorting area, two ends of each sorting roller are fixedly mounted on the frame through bearings, the diameter of each sorting roller is R1, the distance between every two adjacent sorting rollers is L1, a plurality of rows of sorting clasp nails are axially mounted on each sorting roller, the number of each row of sorting clasp nails is M1, the length of each sorting clasp nail is P1, and the clasp nails of every two adjacent sorting rollers are mounted in a staggered manner. Unloosened lumped cake tobaccos in thestrips can be sorted from strip materials, the sorted cake tobaccos can be loosened into pieces, subsequent production requirements can be met, and the cake tobacco sorting and loosening device is simple in structure, convenient to use and good in loosening effect.

Owner:CHINA TOBACCO HENAN IND

Children water-writing interior wall paint capable of turning transparent while contacting water

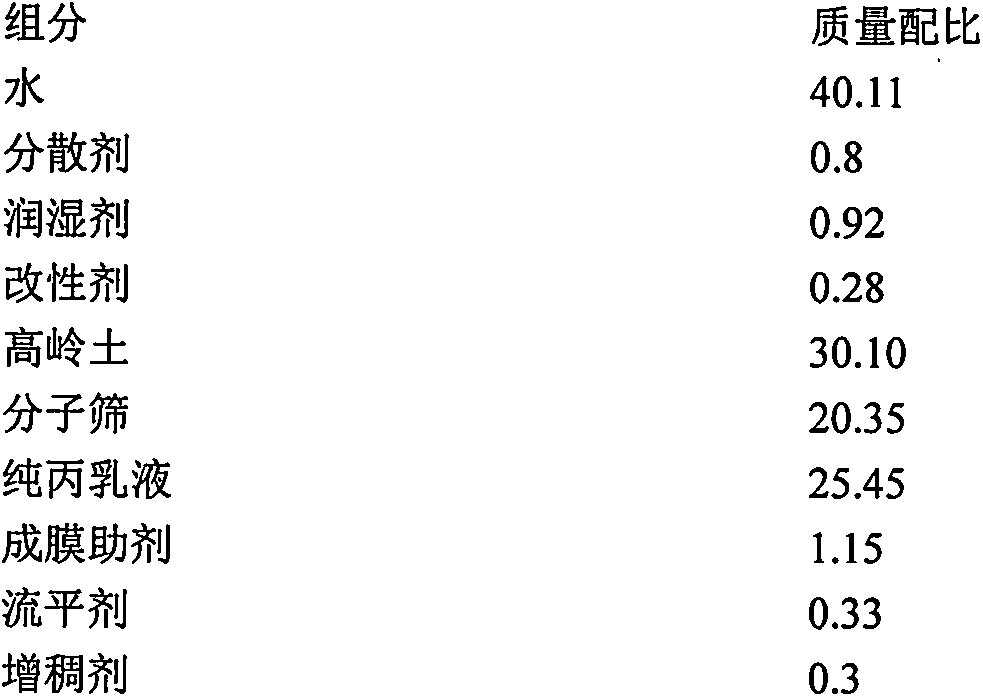

The invention discloses a children water-writing interior wall paint capable of turning transparent while contacting water. According to the paint, pure acrylic latex is adopted as a bonding agent, and kaolin and molecular sieve are adopted as main filling materials. The paint comprises other components of water, a dispersing agent, a wetting agent, a film-forming aid, a leveling agent, and a thickening agent. The components are well mixed and stirred according to a certain sequence and ratio, and the paint is obtained. The paint is sprayed on a wall or above a primer through a spraying or brushing process. The coating is air-dried or baked, such that the coating is cured into a film. The water-writing paint is mainly used for interior walls of rooms for children. With the characteristic that the paint is turned transparent while contacting water, children can draw on the wall with water as a pigment. With the evaporation of water, the wall can regain color, such that the inconvenience of cleaning is avoided.

Owner:孟祥昀

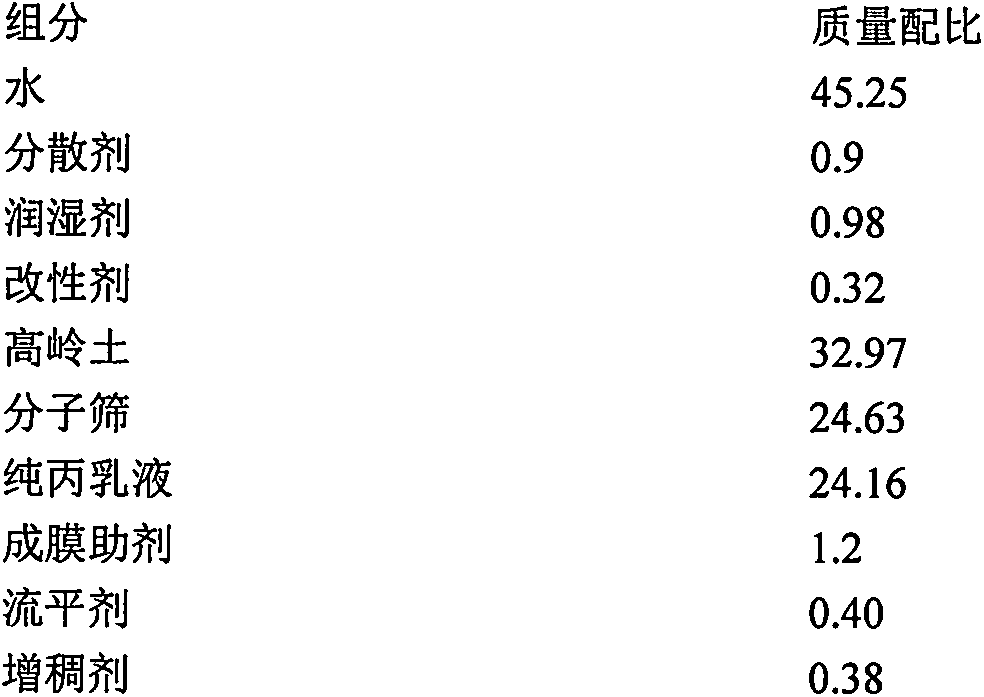

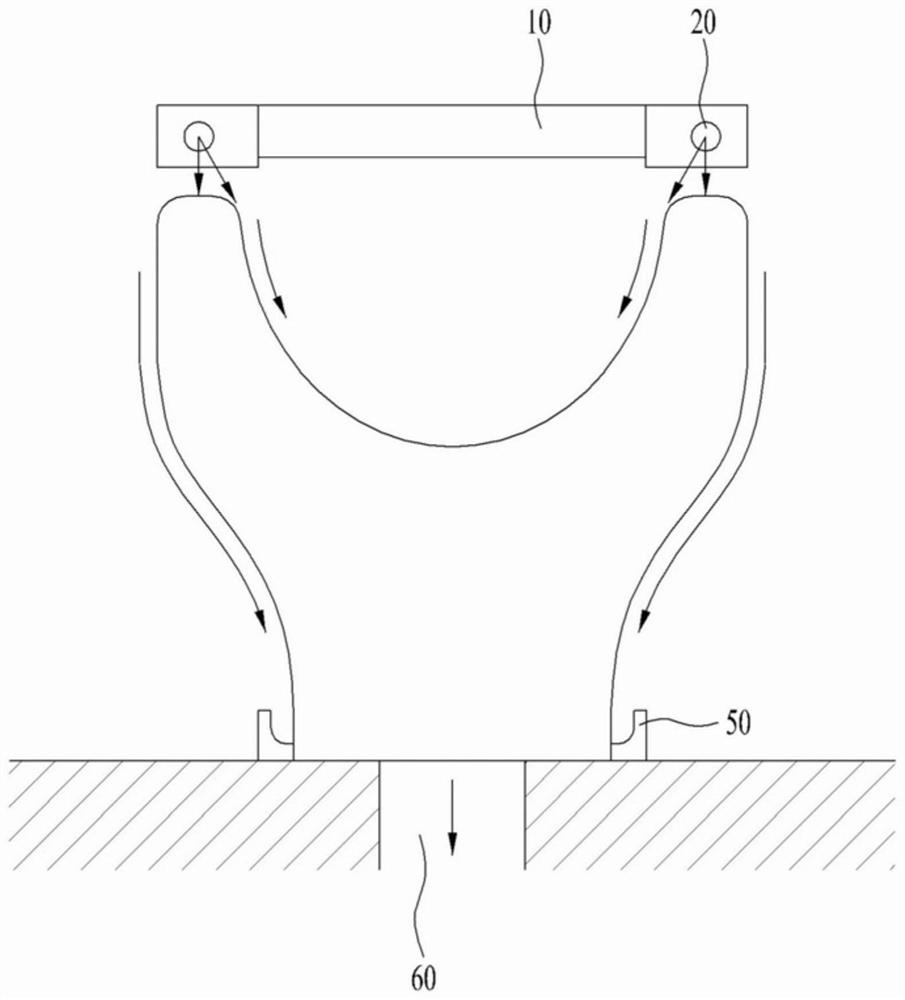

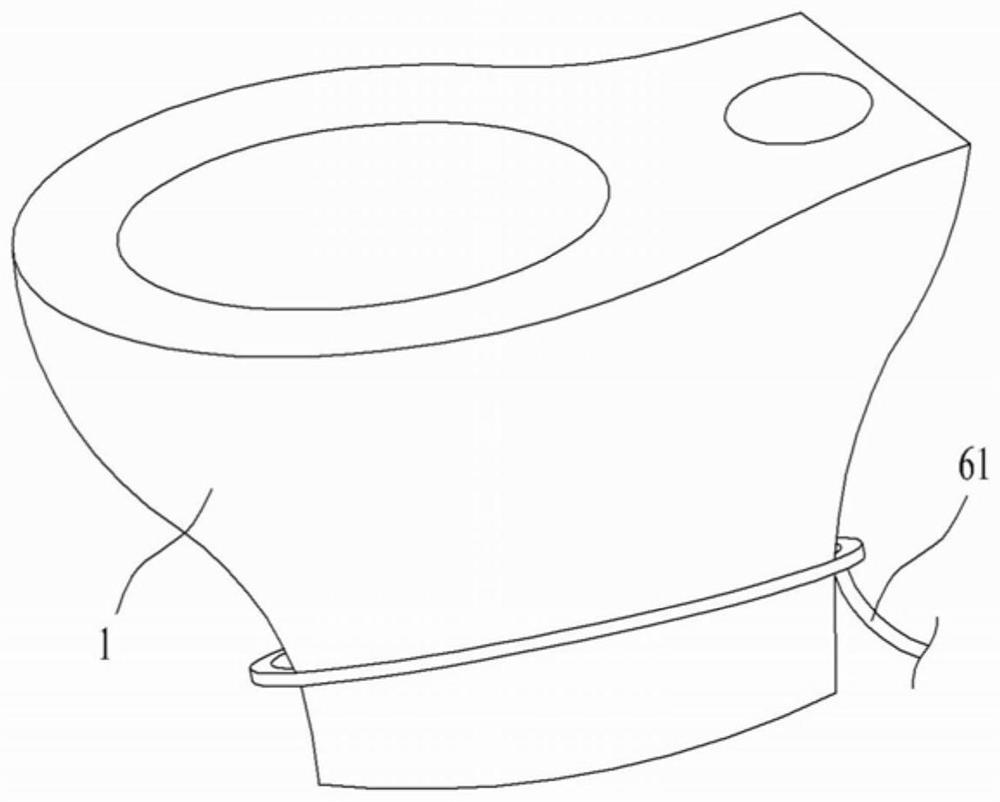

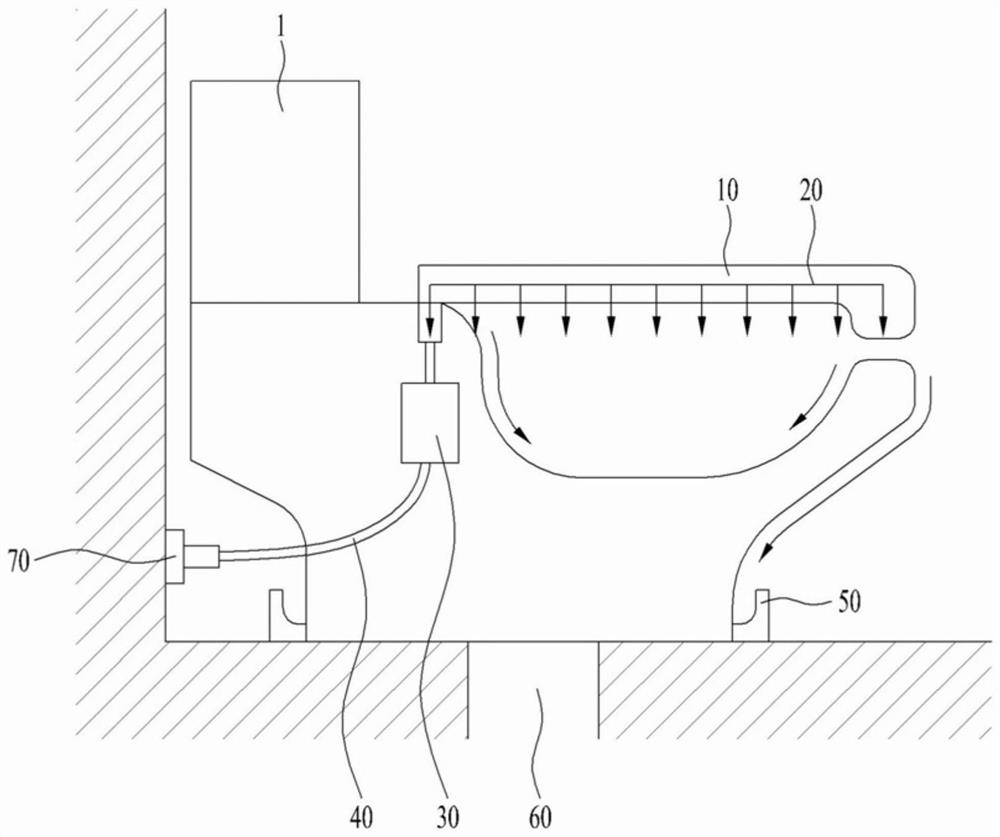

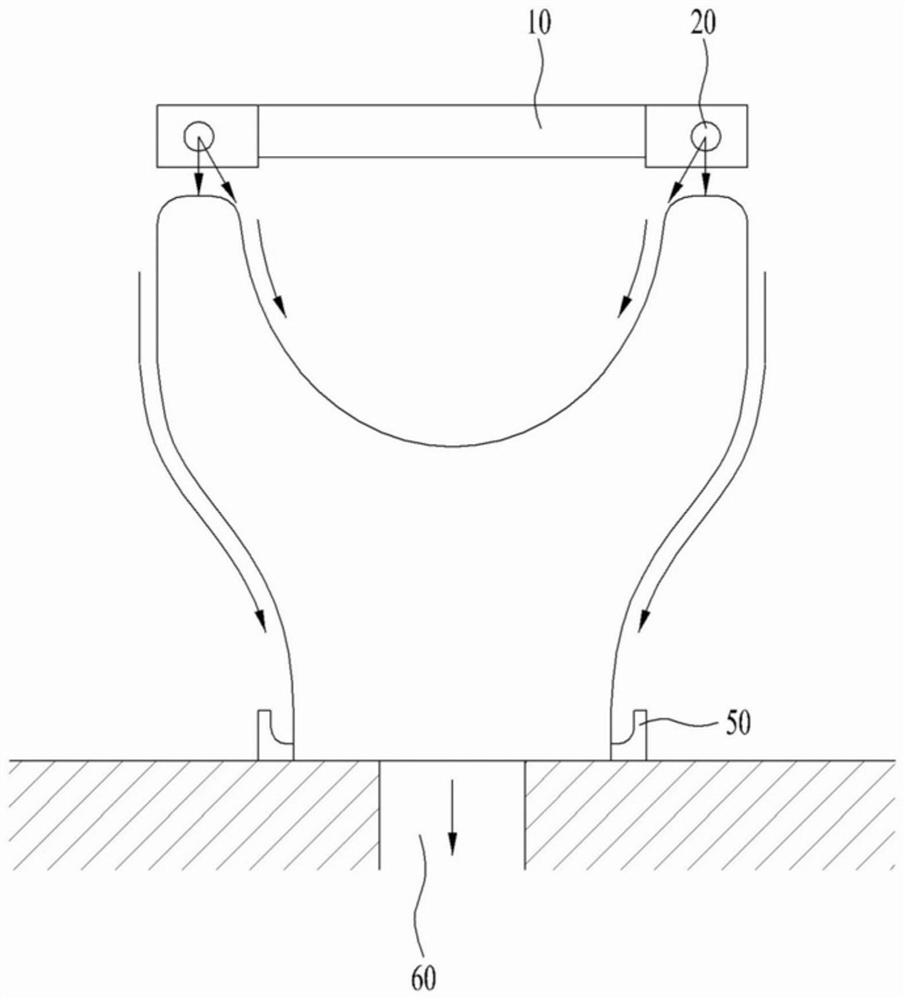

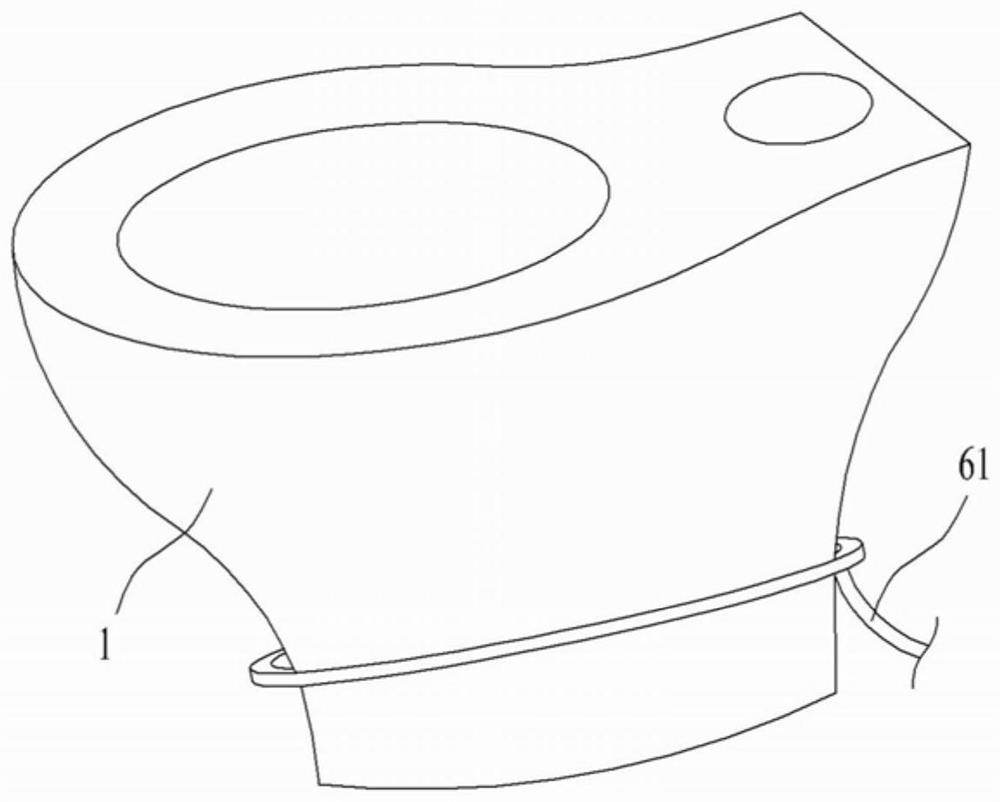

Automatic toilet cleaner and automatic cleaning toilet including same

ActiveCN112302126AKeep and manage cleanlinessLess Cleaning HassleWater closetsFlushing devicesTap waterMechanical engineering

An automatic toilet cleaner and an automatic cleaning toilet including the same are provided. In one aspect of the present disclosure, an automated toilet cleaner is provided. The automatic toilet cleaner may include: a cleaning solution tank configured to contain a cleaning solution; a spray pipe configured to be connected to the cleaning solution tank and to spray a cleaning solution onto an endportion of the toilet seat supporting unit of the toilet; and a cleaning solution tank configured to collect a portion of the sprayed cleaning solution flowing out of the toilet. In this case, the cleaning solution tank may be configured to be supplied with tap water by connection to the water supply pipe and to supply the cleaning solution to the spray pipe.

Owner:魏敬一

Noiseless aluminum alloy section cutting device

InactiveCN108746848ASolve noise pollutionReduce labor intensityMetal sawing devicesMetal sawing accessoriesInsulation layerDrive shaft

The invention discloses a noiseless aluminum alloy section cutting device. The noiseless aluminum alloy section cutting device comprises supporting columns, a sound insulation layer, a fixed clampingdevice, a front cover, a soundproof box, a rear cover, a first servo motor, a chain, a fragment box, a rotary shaft, a fixed block, a saw blade, rocking bars, moving plates, bases, grooves, fixed baffles, a rectangular hole, a lead screw, workbench slide rails, second servo motors, driving shafts, nut seats, bearings and a workbench. The four supporting columns are arranged at the four corners ofthe lower portion of the workbench. The fixed block is arranged below the workbench. One side of the fixed block is connected with one end of the rotary shaft. The saw blade is welded to the other endof the rotary shaft. A gear is arranged on the position, between the saw blade and the fixed block, of the rotary shaft. The first servo motor is arranged on one side of the fixed block. The output end of the first servo motor is connected with the gear on the rotary shaft through the chain. The sound insulation layer is arranged on the lower portion of the workbench. The fragment box is arrangedbelow the sound insulation layer. The soundproof box is arranged on the workbench.

Owner:浙江长兴鼎昌金属制品有限公司

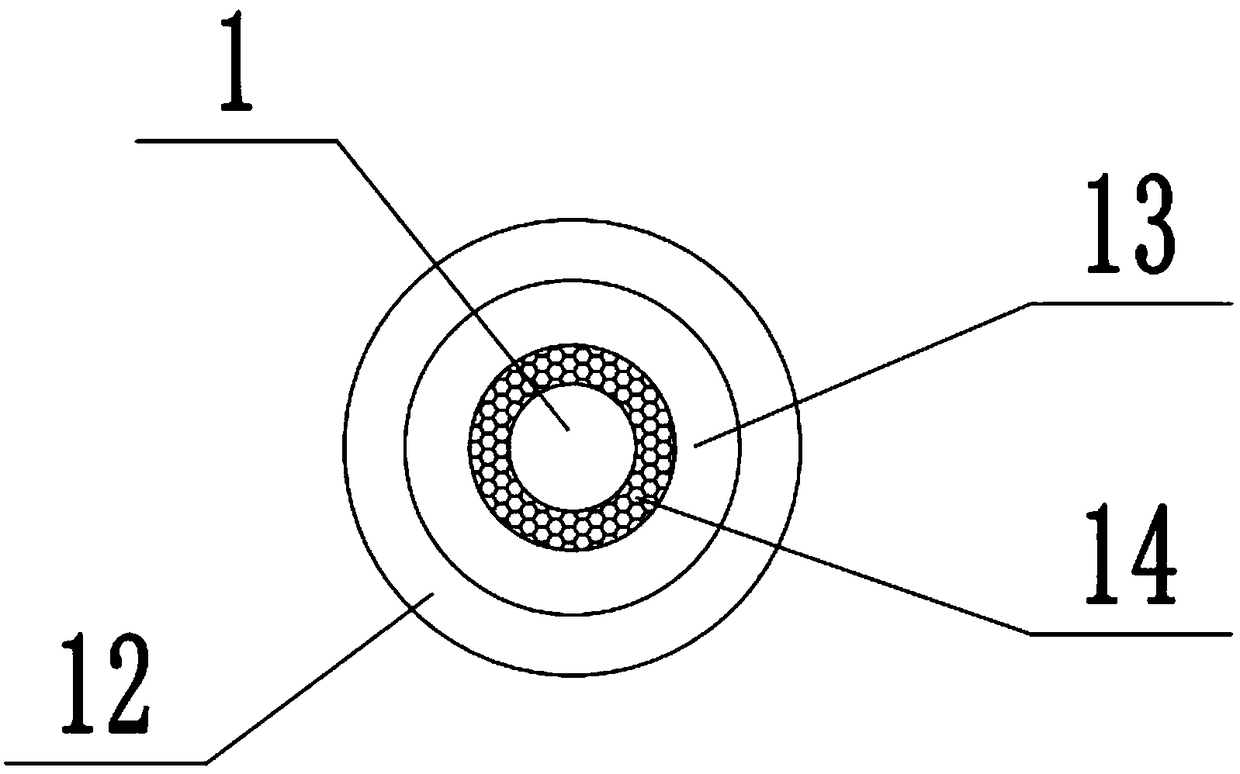

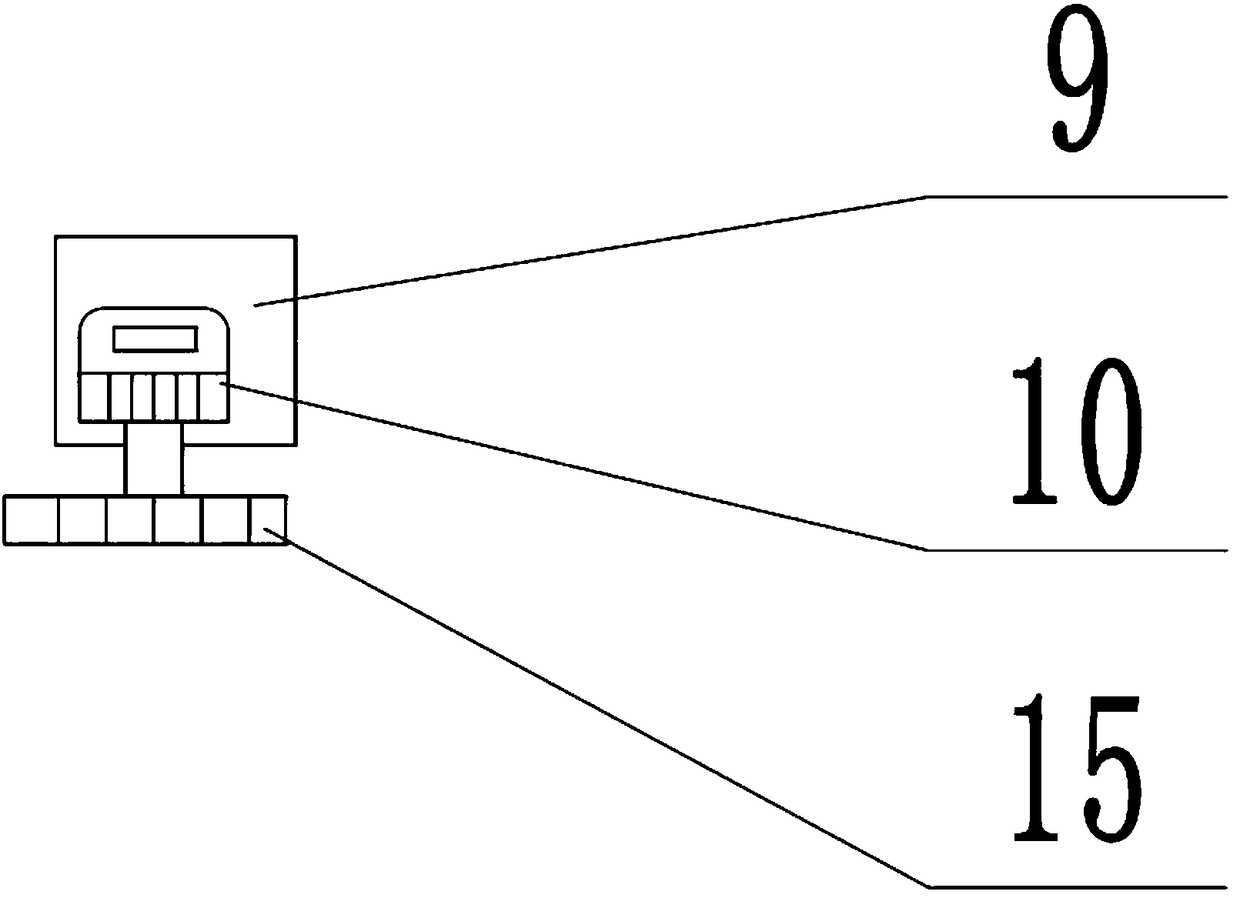

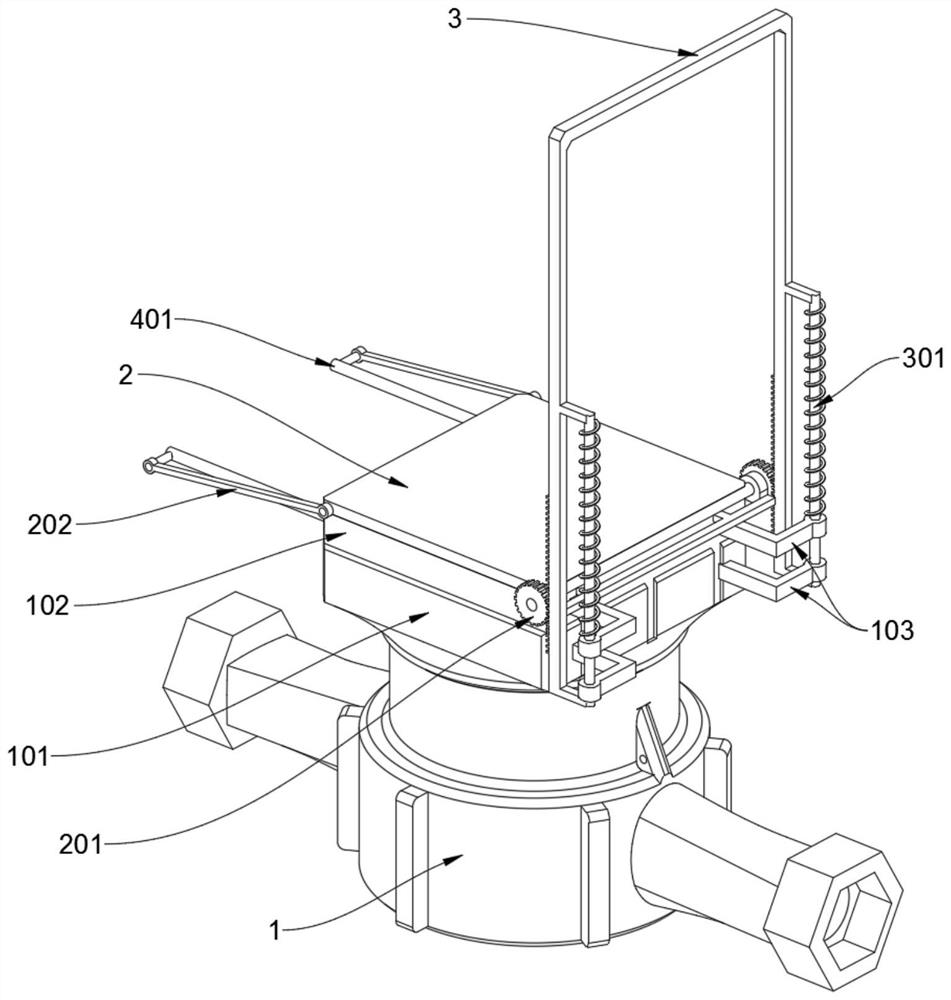

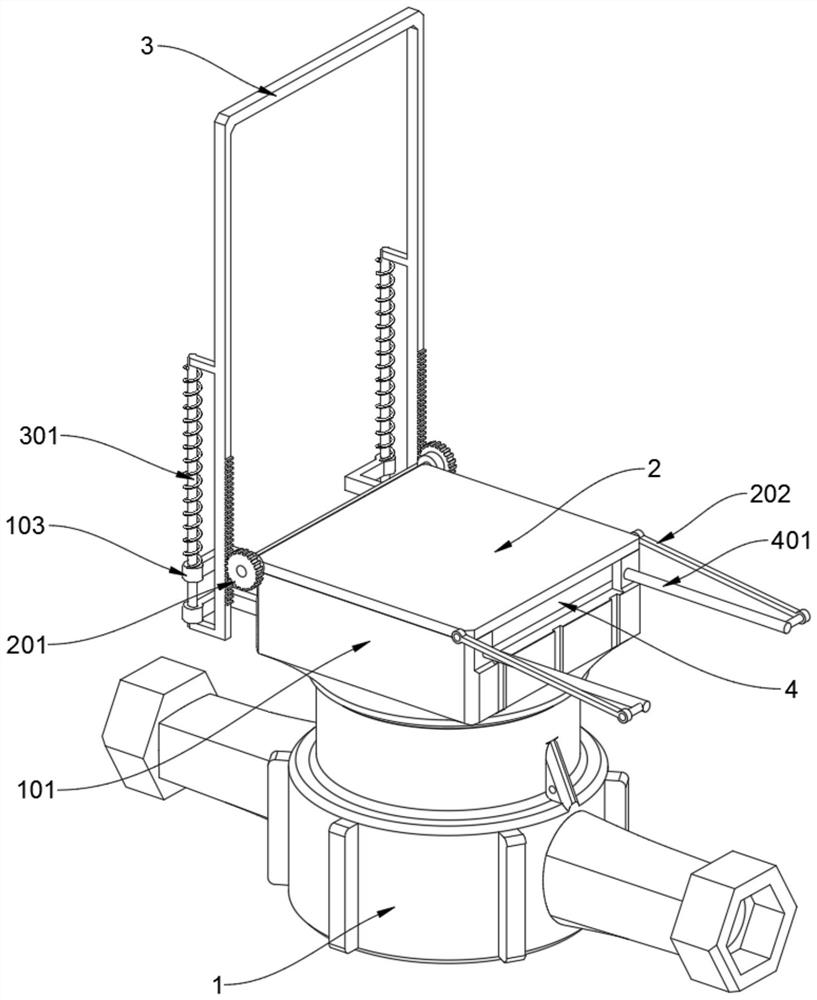

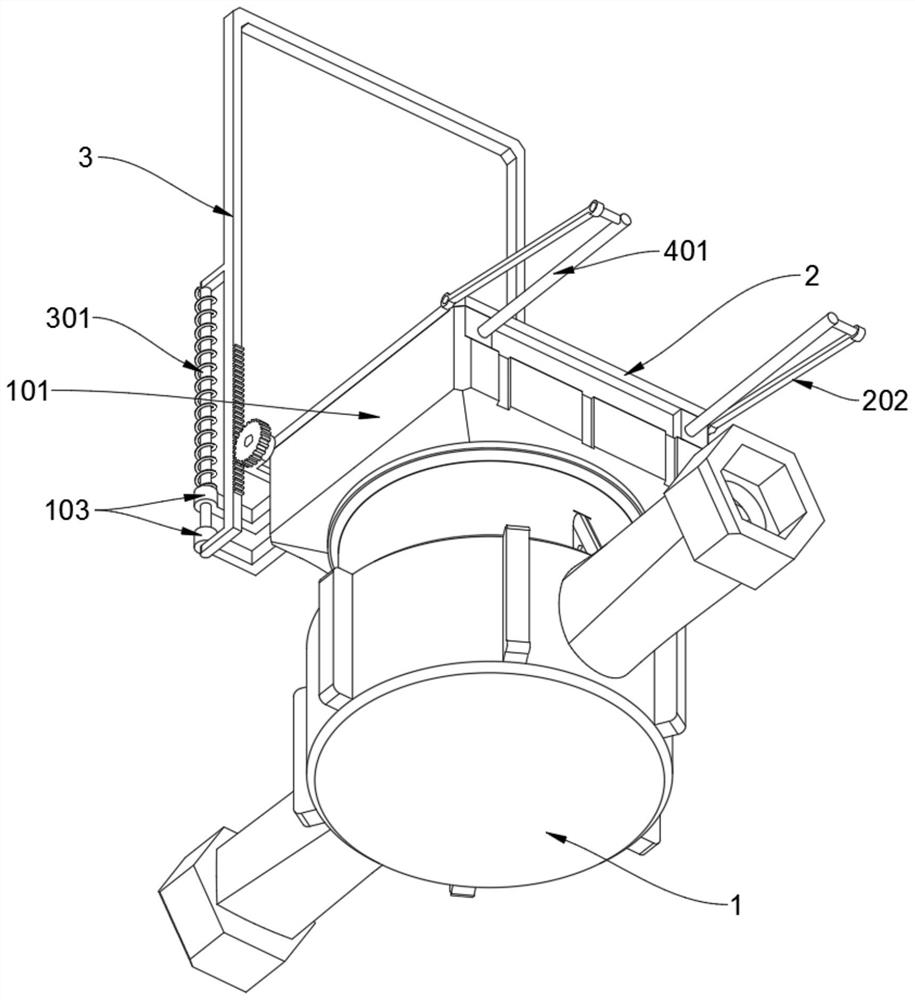

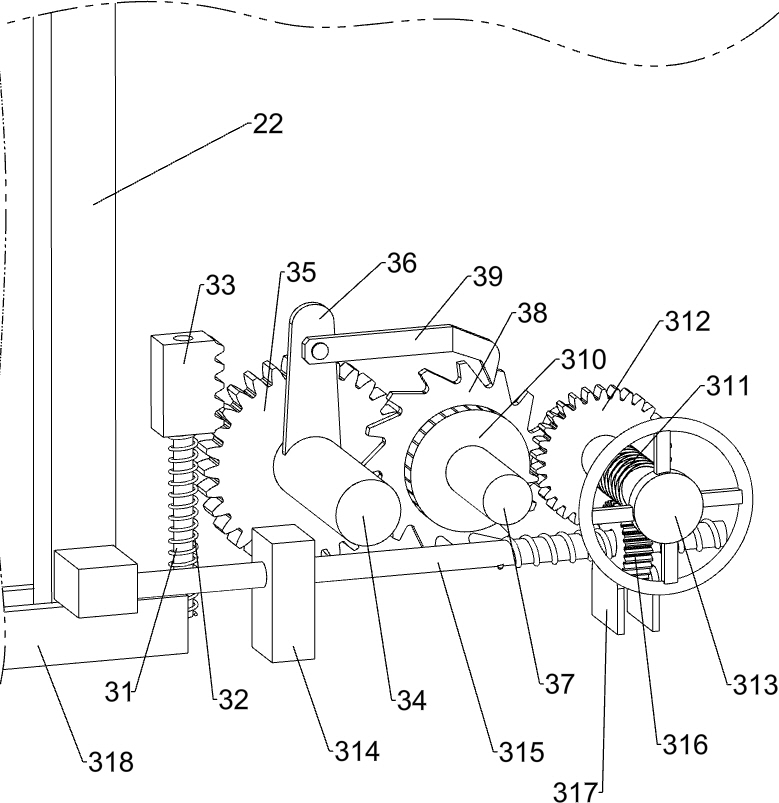

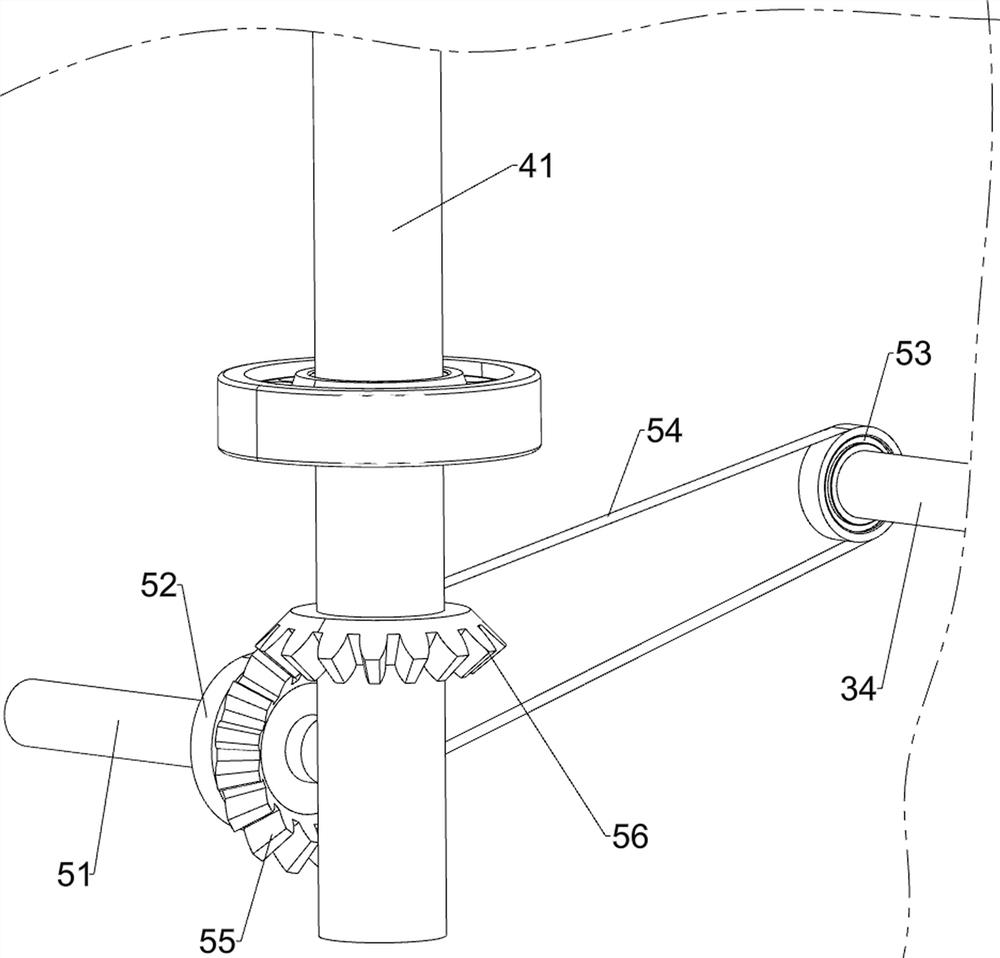

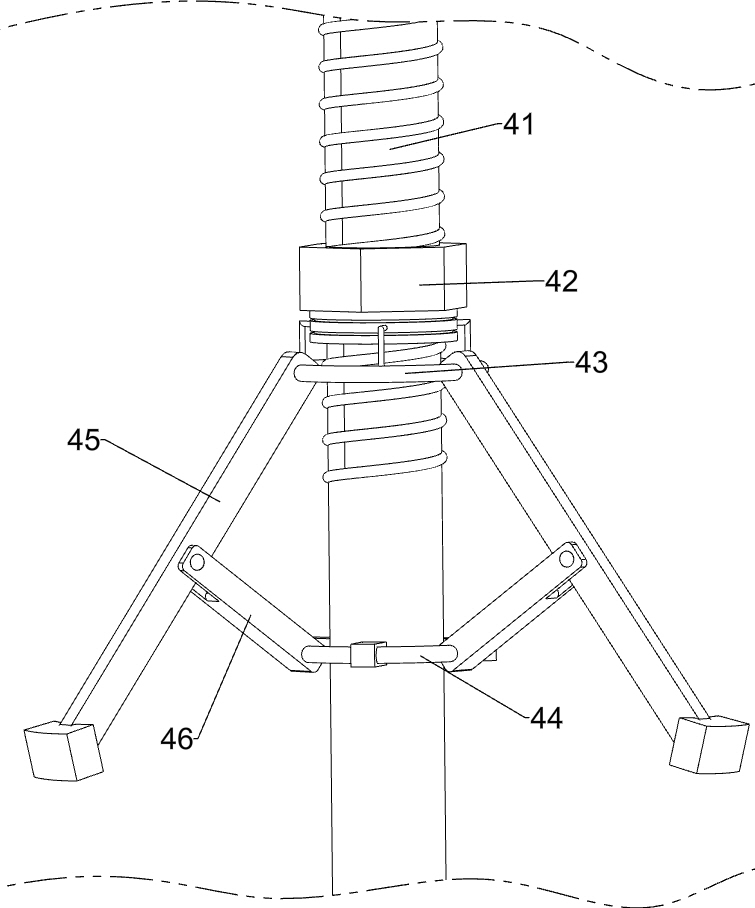

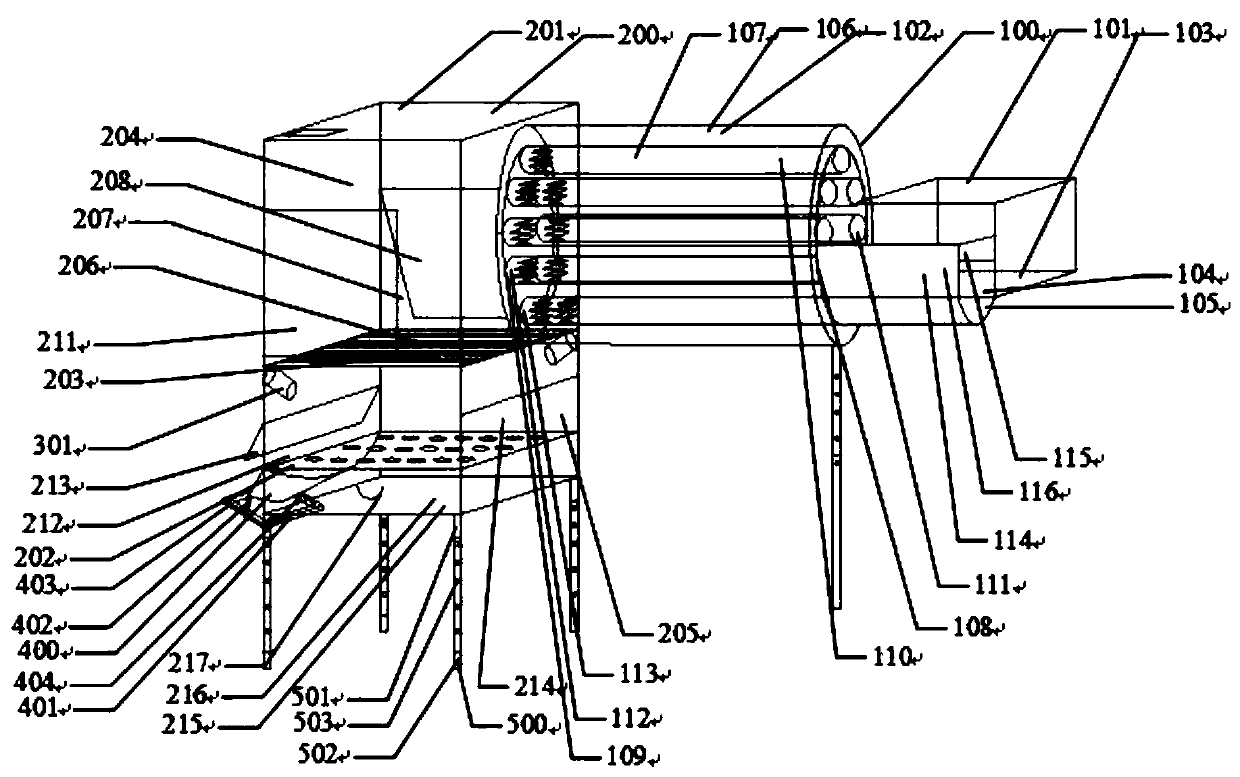

Water meter

The invention discloses a water meter, relates to the technical field of water meters, and solves the problems that according to an existing household water meter, due to the fact that sandy soil is easily accumulated on sealing glass of a dial plate and water drops are condensed, normal reading checking is obstructed by shielding, manual cleaning by personnel in a deep pit is needed, and operation is difficult and strenuous. A water meter comprises a water meter body. The water meter body comprises a dial plate and a surrounding frame, the whole water meter body is of a circular structure, the square dial plate is arranged at the top of the water meter body, the surrounding frame is upwards welded to the top end of the dial plate, and a square meter cover rotationally covers an opening in the top end of the surrounding frame; the two vertical positioning shafts are each sleeved with a spring, and the two rows of tooth pieces on the lower half sections of the two driving mechanisms are correspondingly in meshing transmission with the two driven gears. The long-strip-shaped grooves in the enclosure frame can be convenient for the sponge strips to scrape out gravel and mud accumulated in the enclosure frame, so that excessive gravel and mud are prevented from being accumulated in the enclosure frame, and the trouble of additionally manually applying force to clean the gravel and mud is saved.

Owner:沛县科鲁新能源技术服务中心

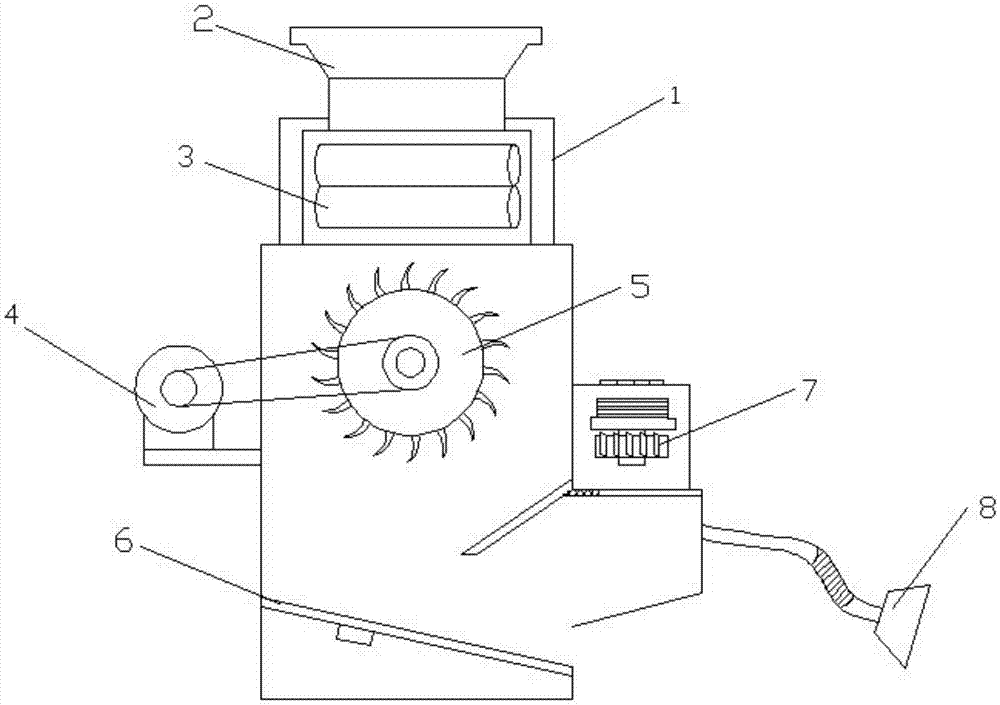

Straw pulverizer absorbing crushed straw

The invention discloses a straw pulverizer absorbing crushed straws. The straw pulverizer comprises a machine body. The upper part of the machine body is provided with a feed port. Two rolling wheels which rotate in reverse directions are arranged below the feed port. A belt pulley of a drive motor on the outer side of the machine body is connected with a belt pulley on a smashing roll rotating shaft in the machine body through a belt. A smashing roll is below the rolling wheels. A long plate which is in an inclined manner and connected with a discharge port is arranged below the smashing roll. One side of the machine body, above the discharge port, protrudes a housing, and is provided with a fan. The side surface of the machine body, protruding the housing, is connected with a material absorbing cover through a pipe. The fan and a pipe mouth which is connected with the protruded housing of the machine body are separated by a separating plate. The lower part of the fan and a smashing cavity of the smashing roll are separated by an inclined plate. The straw pulverizer absorbing crushed straws can roll extra air out of the straws in advance, so as to improve smashing efficiency. The straw pulverizer absorbing crushed straw can absorb fallen crushed straws into the discharge port to discharge the crushed straws, so as to reduce troubles of cleaning.

Owner:CHONGQING KUNQI BUILDING MATERIALS CO LTD

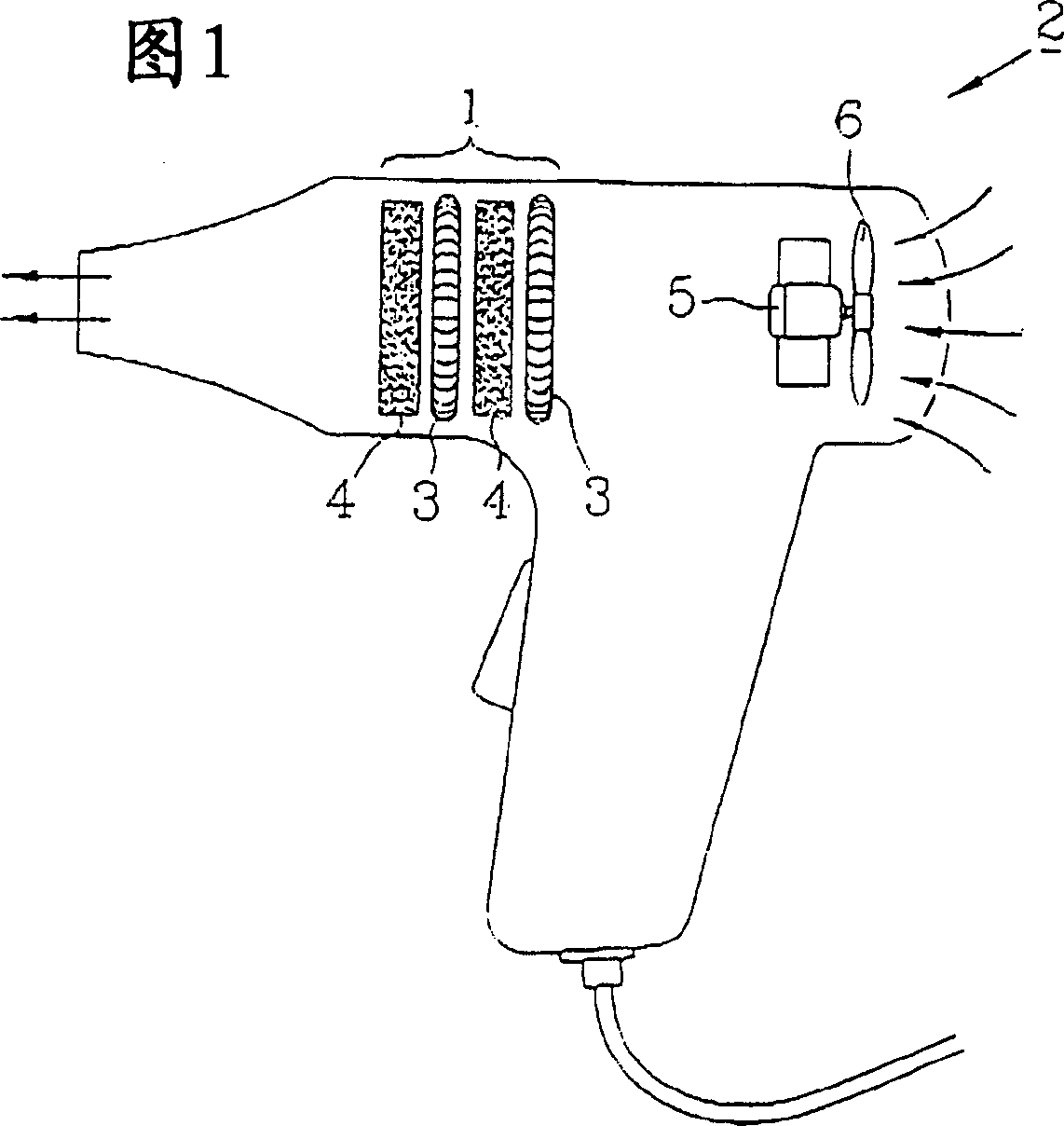

Household electric appliances

InactiveCN1620235AGood effectStay semi-permanentSelf-cleaning stoves/rangesPhysical/chemical process catalystsHome applianceTitanium oxide

Owner:NAGATA GIKEN CO LTD +1

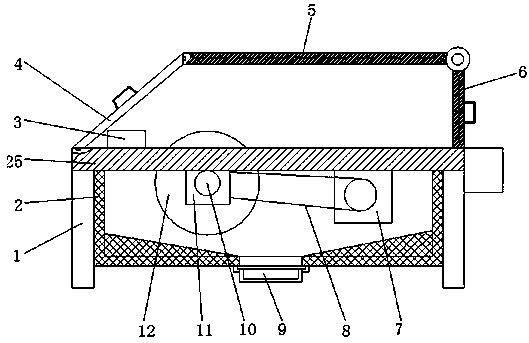

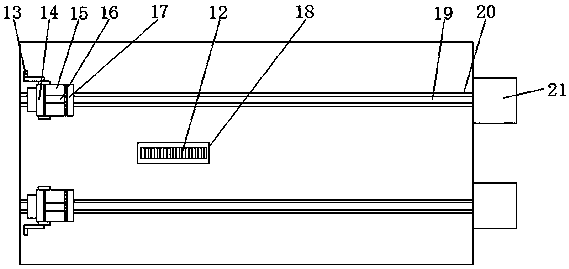

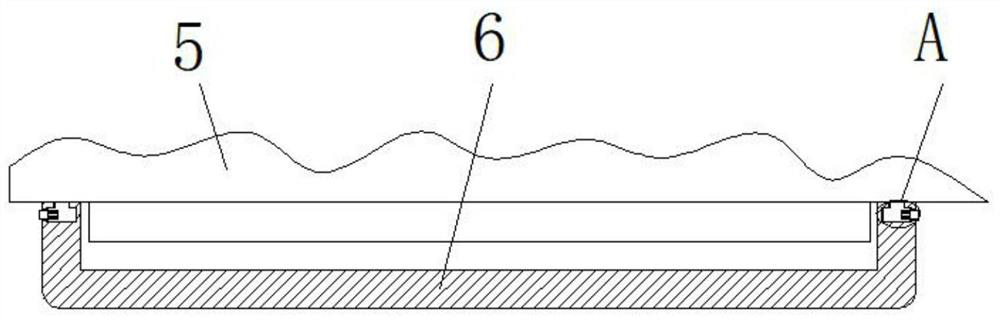

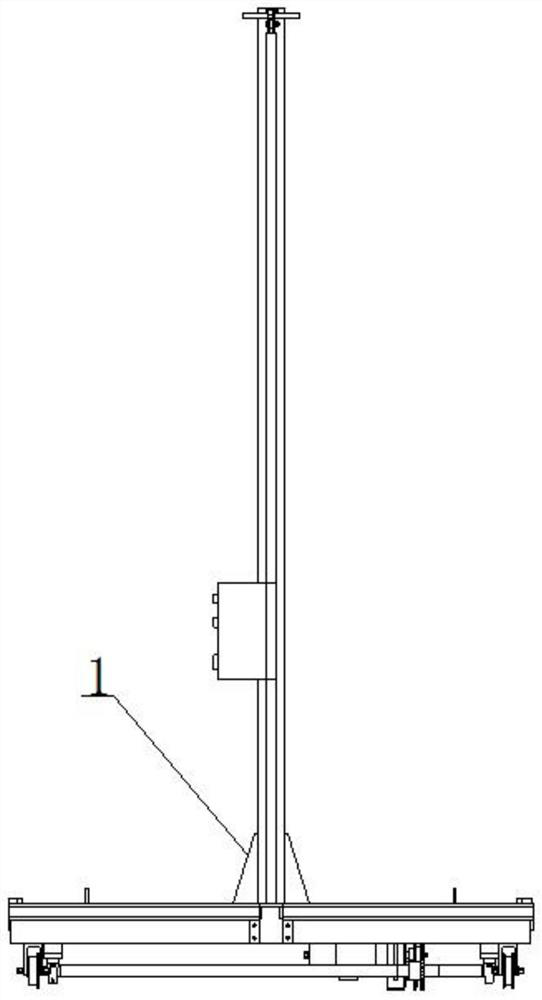

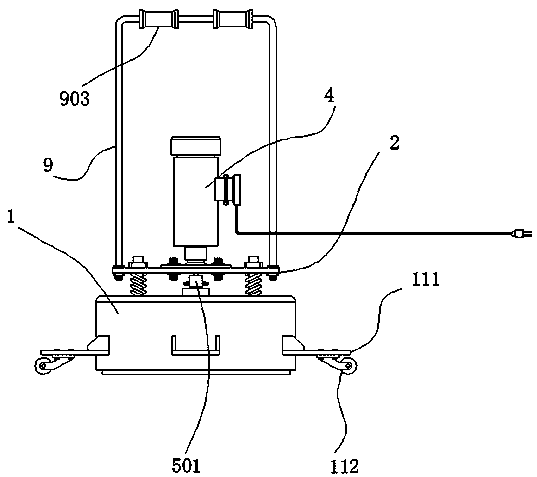

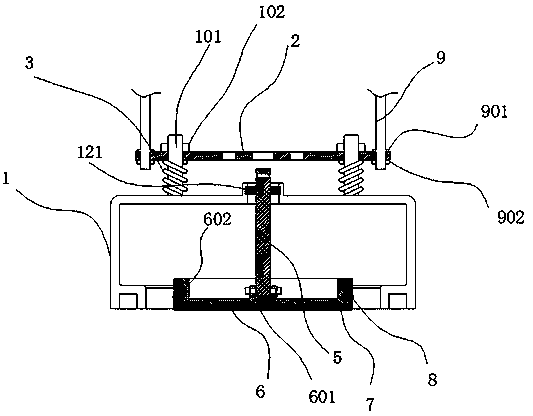

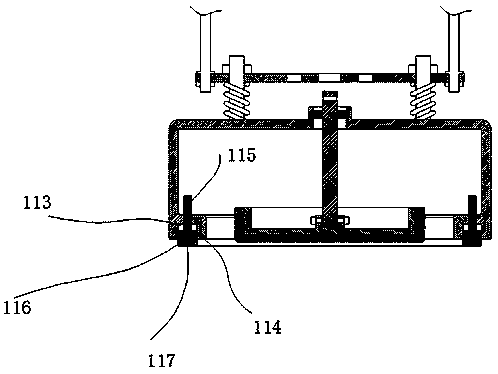

Energy-saving and environment-friendly clothing material non-contact type lifting, positioning and drying equipment

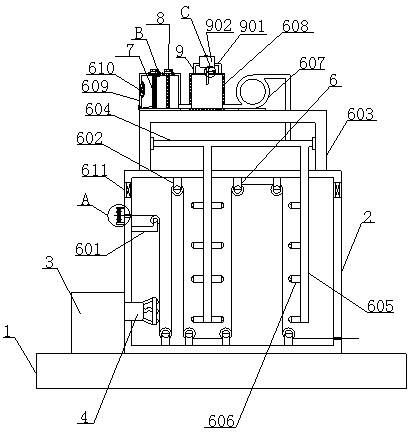

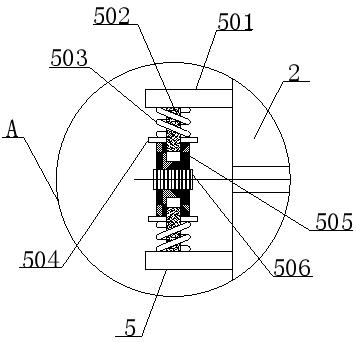

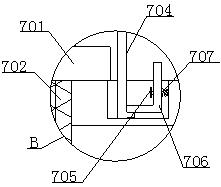

InactiveCN112197558AWill not be damagedLess Cleaning HassleMechanical cleaningPressure cleaningYarnProcess engineering

The invention discloses an energy-saving and environment-friendly clothing material non-contact lifting, positioning and drying equipment. The energy-saving and environment-friendly clothing materialnon-contact lifting, positioning and drying equipment comprises a base, a drying box, a steam generation box, an ironing head, a cleaning mechanism, a drying mechanism, a dust filtering assembly, a moisture filtering assembly and an aroma adding mechanism, wherein the drying box is fixedly installed at the top of the base, the steam generation box is fixedly installed on the left side of the drying box, the ironing head is fixedly installed on the right side of the steam generation box, and the cleaning mechanism is fixedly installed on the left side of the drying box. According to the energy-saving and environment-friendly clothing material non-contact lifting, positioning and drying equipment, the dust filtering assembly and the moisture filtering assembly are arranged, the device can filter dust, wool yarn and moisture in outside air during the use of the equipment, meanwhile, the dust filtering assembly and the moisture filtering assembly are convenient to mount and dismount, by arranging the aroma adding mechanism, the moisture can heat and vaporize aroma liquid through a heating box during use, and the vaporized aroma liquid is mixed with air through a conveying pump and sprayed on the surface of a clothing material.

Owner:温州宇岚科技有限公司

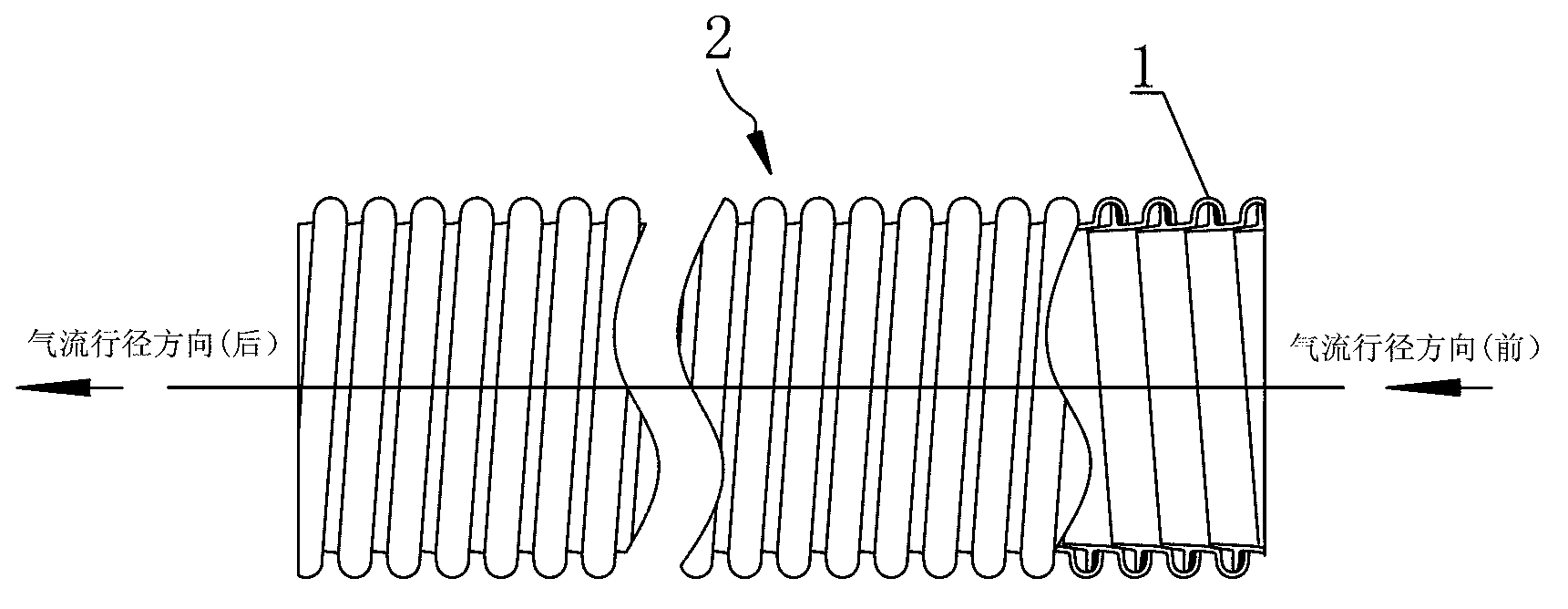

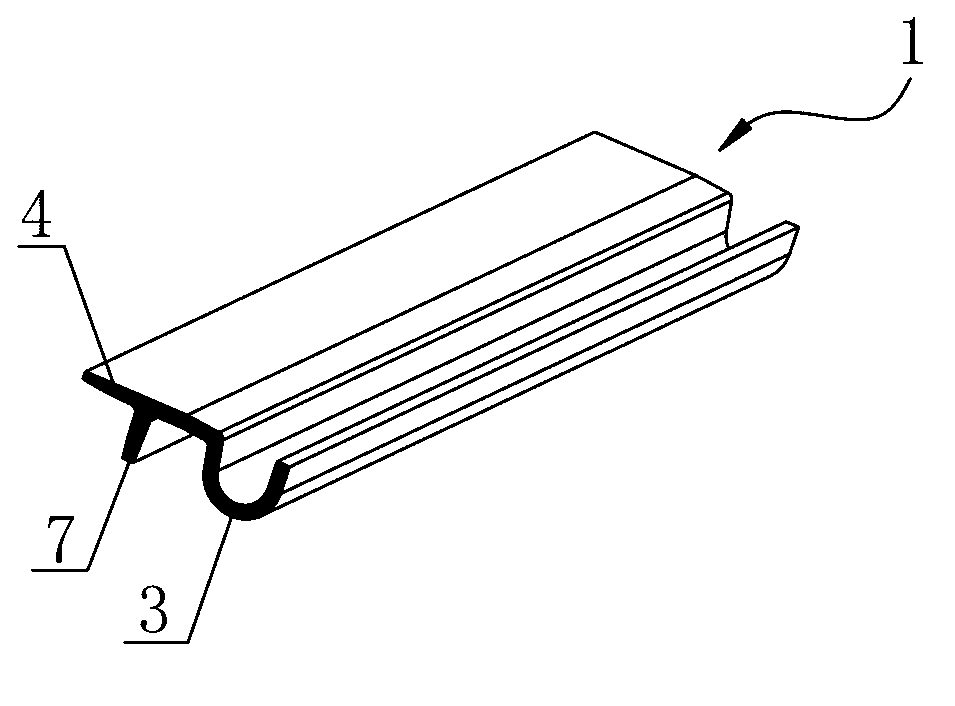

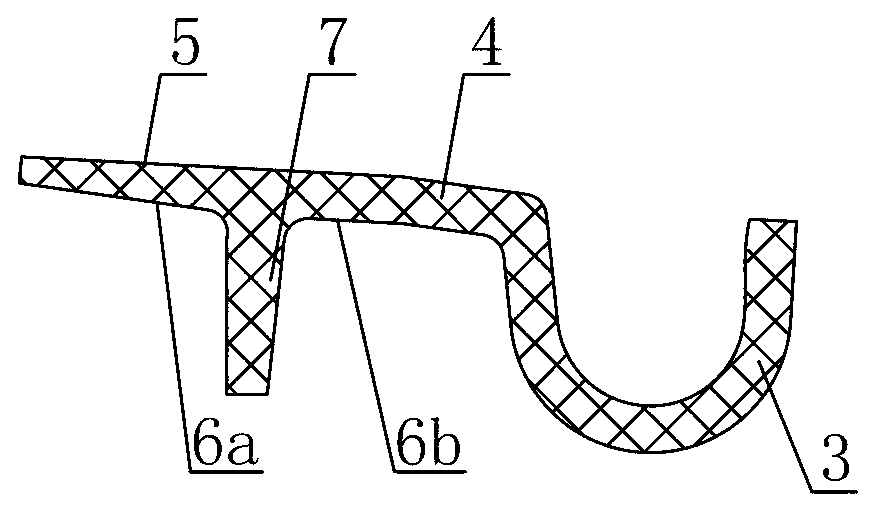

Hose pipe of dust collector

InactiveCN103222835ALess Cleaning HassleReduce extrusion pressureSuction hosesLap jointRelative motion

The invention relates to a hose pipe of a dust collector. The hose pipe comprises a strip-shaped soft bars, wherein the strip-shaped soft bar is spirally adhered to form a pipe body; the strip-shaped soft bar comprises a groove part and a lap joint part connected with one port of the groove part; the lap joint part is provided with an inner surface and an outer surface; the lap joint part slantwise extends from one port of the groove part to the direction away from one side of the port; when the strip-shaped soft bar is spirally adhered to form the pipe body, the outer surface of the lap joint part of a previous ring is in lap joint on the inner surface of the lap joint part of a next ring along two adjacent rings in the front and back directions of an airflow path to shield the groove part; and the inner surface of the lap joint part of the previous ring is higher than that of the lap joint part of the next ring, so that a laminated inner surface of the pipe body is formed by the inner surface of the lap joint part. As a groove in the inner surface of the hose pipe is shielded, dust does not accumulate in the groove part; as the lap joint parts of the previous and next rings can generate relative movement, bending, stretching and compression are not affected; and as the inner surface of the hose pipe is laminated, the air flow resistance is reduced, the energy loss is decreased, and the noise is reduced.

Owner:SUZHOU HOWELL ELECTRIC APPLIANCES

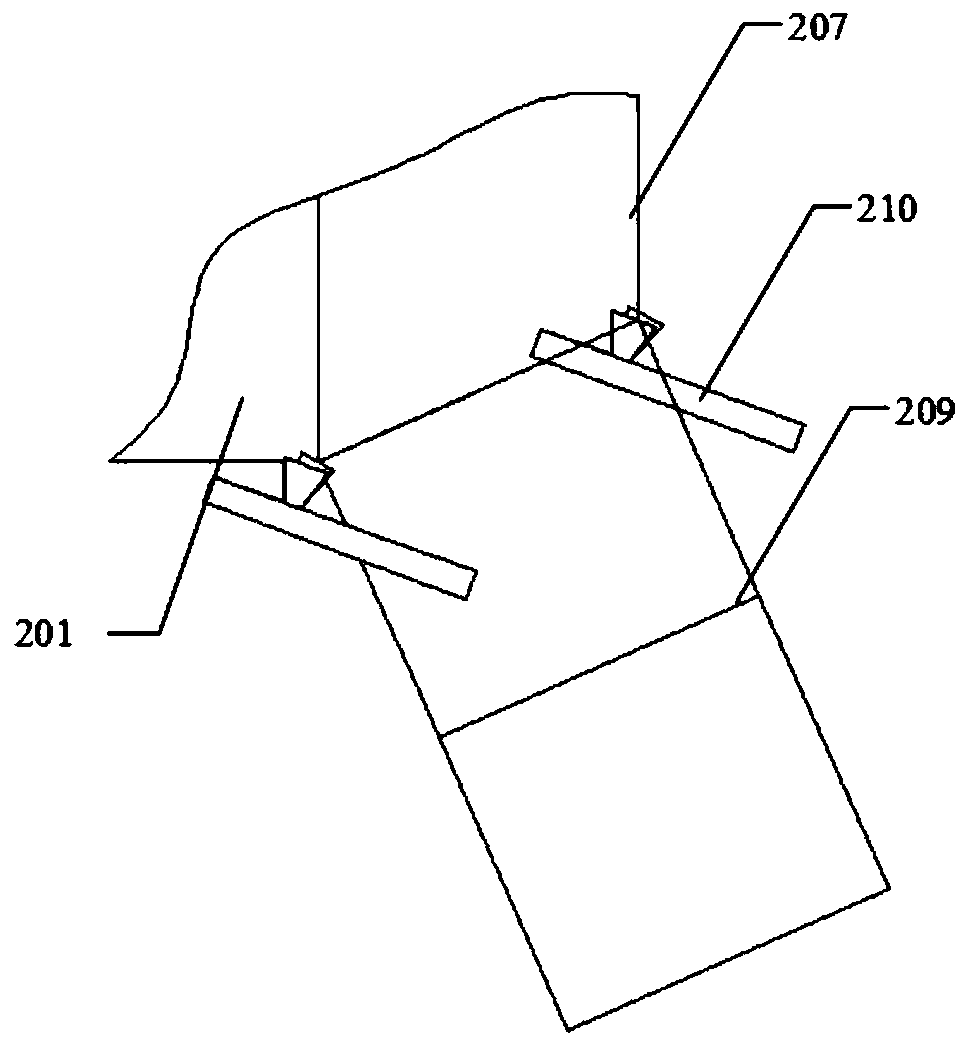

A Spray Gun with Adjustable Angle for Easy Collection of Powder

ActiveCN110614182BRealize the collectionImprove collection efficiencySpray boothsEngineeringStructural engineering

Owner:苏州肯美特设备集成股份有限公司

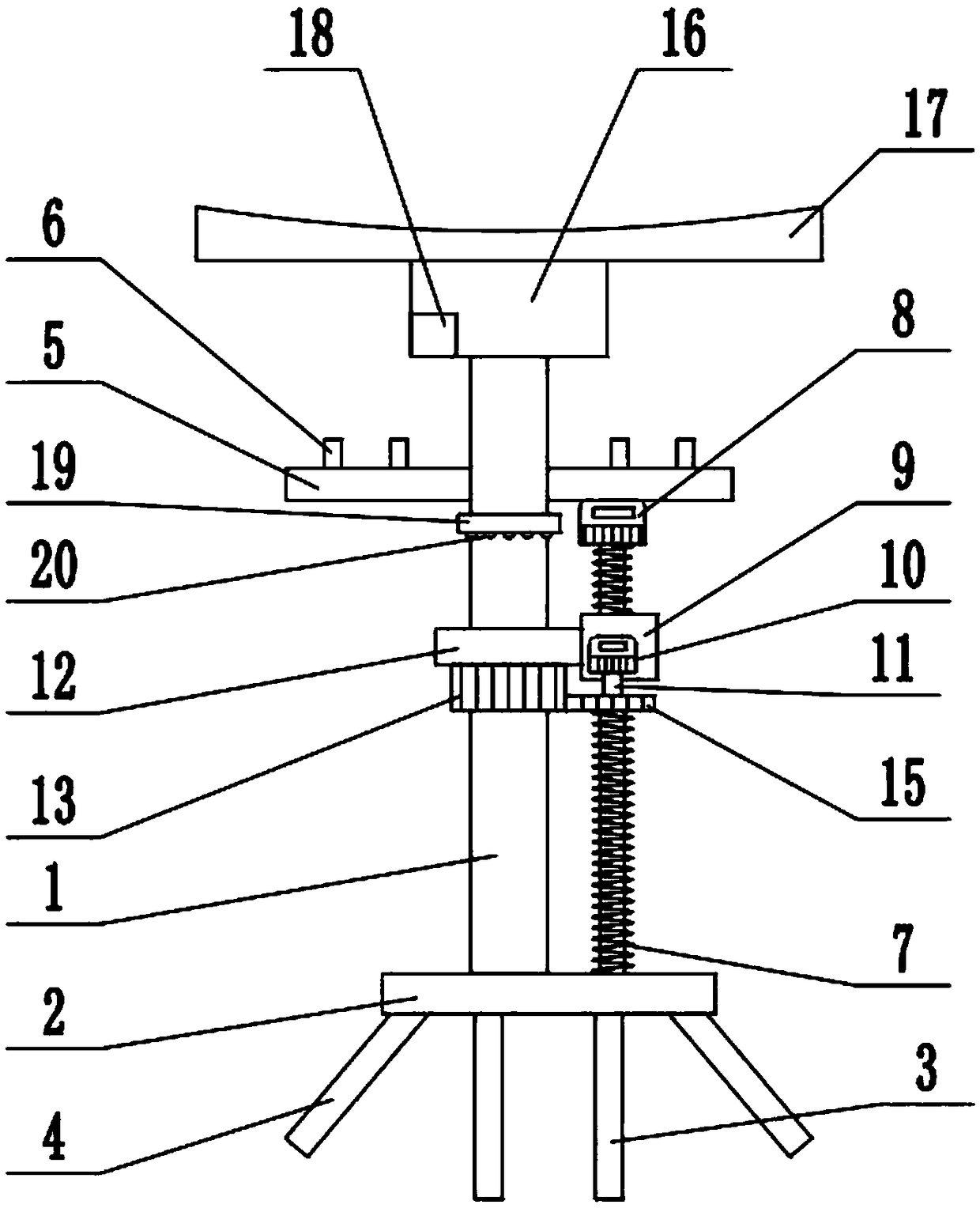

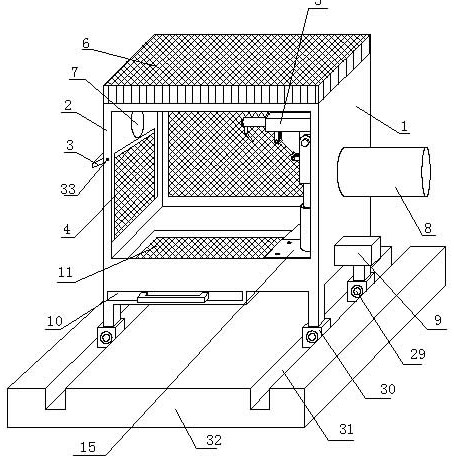

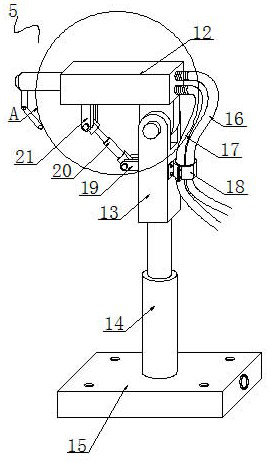

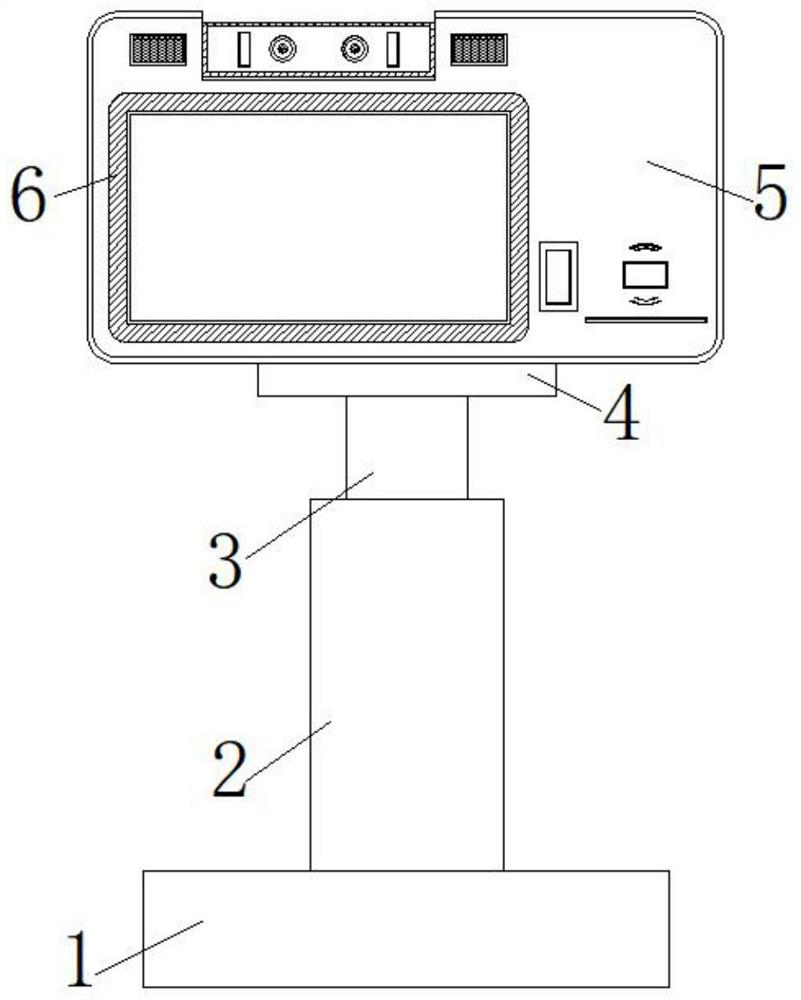

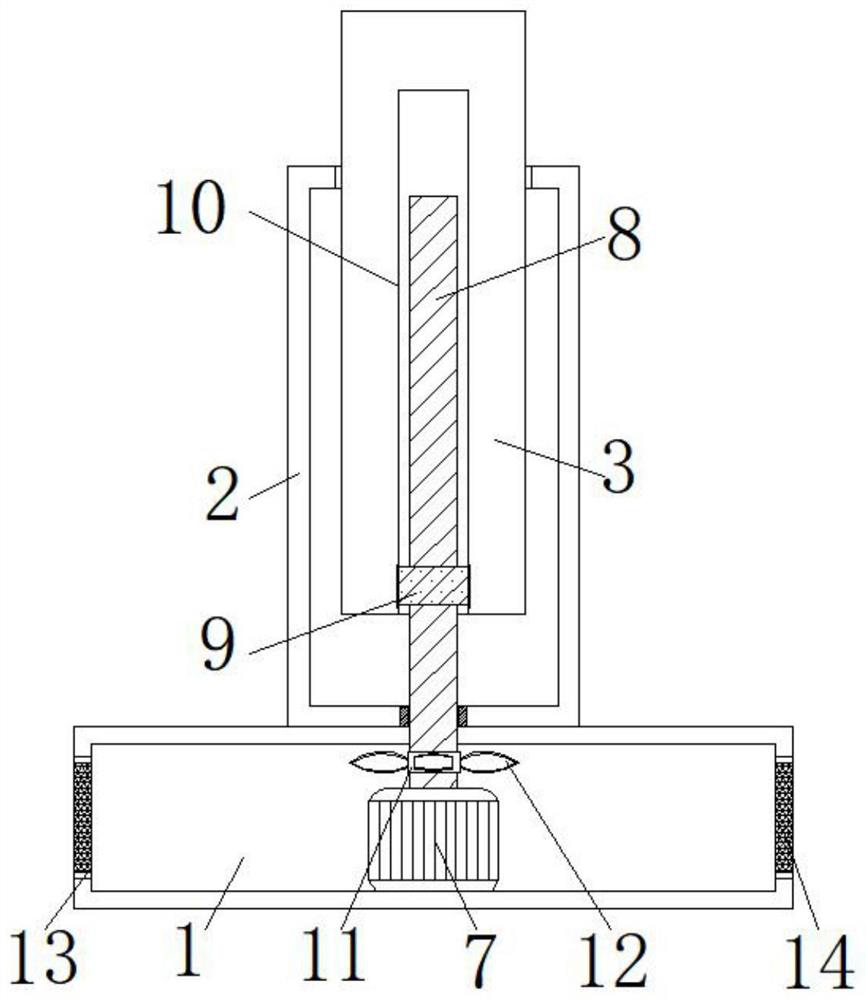

Terminal equipment based on solution of enterprise informatization

InactiveCN112032516AExtended service lifeAvoid loss of productivityFouling preventionStands/trestlesElectric machineBusiness enterprise

The invention discloses terminal equipment based on solution of enterprise informatization. The terminal equipment comprises a base; a fixing cylinder is fixed to the top end of the base; a supportingcolumn movably penetrates through the inner side of the fixing cylinder and extends to the outer wall of the top end of the fixing cylinder; a terminal device host is fixed to the top of the supporting column; a sliding groove is formed in the bottom of the supporting column; a forward and reverse rotation motor is fixed in the cavity of the base; an output shaft of the forward and reverse rotation motor is rotationally connected with a threaded rod; the threaded rod rotationally penetrates through the outer wall of the bottom end of the fixing cylinder; the threaded rod extends into the sliding groove; the outer wall of the threaded rod is rotationally sleeved with a ball nut; the ball nut is fixed to the surface of the inner side of the sliding groove; the outer wall of the forward andreverse rotation motor is fixedly sleeved with a fixing casing pipe; fan blades distributed at equal intervals are fixed to the outer surface of the fixing casing pipe; heat dissipation windows are formed in the surfaces of the two sides of the base; and dustproof nets are fixed in the heat dissipation windows through bolts. By the aid of the arranged forward and reverse rotation motor, the heightof the equipment can be adjusted quickly, and meanwhile, heat dissipation can be performed on the forward and reverse rotation motor.

Owner:上海梓方信息科技有限公司

Rice steamer planing device

ActiveCN112157729APlaned evenlySame thicknessFlat surfacing machinesBark-zones/chip/dust/waste removalAgricultural scienceAgricultural engineering

The invention relates to planing equipment, and particularly relates to a rice steamer planing device. The rice steamer planing device can automatically plane a rice steamer without wasting labor or hurting hands. The rice steamer planing device comprises a support, a planing assembly, a pushing assembly and a placing assembly, wherein the planing assembly is installed on the support, the pushingassembly is installed on the support, and the placing assembly is installed on the support. The rice steamer planing device is provided with a rotating assembly, so that the rice steamer can be planedmore uniformly, the thickness degree is the same, and the quality of the rice steamer is better; the rice steamer planing device is provided with a collecting frame, so that falling wood chips can becompletely collected, the trouble of later cleaning is reduced, and a user is more free from worry; and the rice steamer planing device is simple and convenient to operate, the hands do not need to be in contact with an edge tool, and people are not prone to being injured.

Owner:临沂临港国有资产运营集团有限公司

A corn thresher that can realize threshing and packaging in one

ActiveCN107896649BImprove threshing efficiencyGuaranteed outputThreshersCircular discAgricultural engineering

The invention discloses a corn thresher capable of integrating threshing and separate packaging. The corn thresher comprises a feeding device, a material shaking device and a second clapboard arrangedin a second shell; the feeding device comprises a shelving basket and a feeding cylinder, and the feeding cylinder includes a first shell and a feeding mechanism; the feeding mechanism comprises a first disk, a second disk and a transfer cylinder; the first disk is arranged at an inlet of the first shell and provided with a first circular hole, the second disk is arranged at the rear end of the first shell and provided with a second circular hole, and the second circular hole is internally provided with annular blades; the transfer cylinder is arranged between the first circular hole and thesecond circular hole; the material shaking device is arranged at the rear end of the feeding cylinder and comprises the second shell, a mesh sieve, a first vibrating mechanism and a second vibrating mechanism; the second clapboard partitions the second shell into an upper chamber and a lower chamber, the upper chamber separates corn kernels and corn cobs, and the lower chamber separates the corn kernels and impurities. By means of the corn thresher, automatic threshing can be achieved, the core kernels, the corn cobs and the impurities are separately treated to facilitate later packaging.

Owner:何亮

Filtering device for medicine research and development

The invention discloses a filtering device for medicine research and development, and relates to the technical field of medicine research and development, the filtering device comprises a filtering assembly, the top end of the filtering assembly is fixedly connected with a feeding assembly, the rear end of the filtering assembly is fixedly connected with a vibration motor, and the front end of the filtering assembly is provided with a filtering groove; a plurality of filter screens are connected to the inner wall of the filter tank through bolts, a slope is fixedly connected to the lower portion of the inner wall of the filter tank, and compared with an existing filter device, the device is smaller in size, better in effect and more convenient to move and carry, various dry materials possibly used in the medicine research and development process can be effectively filtered, and the use effect of the device is improved. Meanwhile, the device drives the materials to vibrate through the vibration motor and drives the materials to move up and down through the supporting base, the material filtering efficiency can be effectively improved, the situation that the materials are stacked on the filter screen is reduced, the distance between the filtering assembly and the ground is kept, and the possible influence of the ground situation on the filtering assembly is reduced.

Owner:孙敏

Plastic dish grid draining rack

InactiveCN105167679APrevent the growth of bacteriaGuarantee a healthy dietKitchen equipmentEngineeringMechanical engineering

The invention discloses a plastic dish grid draining rack, which is convenient in draining; the plastic dish grid draining rack comprises a plastic grid draining rack main body and a base, wherein the plastic grid draining rack main body is clamped in a water collecting cavity inside a base; the base is supported on a table by virtue of supporting legs; an inclined water outlet which is communicated with the water collecting cavity is formed in one side of the base; and a dish holding groove, a chopstick holding groove and a spoon holding groove are formed inside the plastic grid draining rack main body. The draining rack disclosed by the invention has the advantages that the draining rack is capable of removing residual water on tableware timely, so as to effectively prevent the growth of bacteria and to guarantee healthy diet of people; and meanwhile, by aligning the inclined water outlet in the base with a pool, drained water directly flows into the pool instead of flowing onto a table board or floor, so as to avoid a trouble of sweeping.

Owner:唐冬萍

Corn thresher with auto-threshing function

The invention discloses a corn thresher with an auto-threshing function, comprising; a feeding device that includes a storage basket and a feeding barrel, wherein the feeding barrel includes a first shell and a feeding mechanism, the feeding mechanism includes a first disc, a second disc and a transfer barrel, the first disc is arranged at an inlet of the first shell and is provided with a first round hole, the second disc is arranged at the rear end of the first shell and is provided with a second round hole, a circular blade is arranged in the second round hole, and the transfer barrel is arranged between the first round hole and the second round hole; a shaking device that is arranged at the rear end of the feeding barrel and comprises a second shell, a wire screen, a first vibrating mechanism and a second vibrating mechanism, wherein a second partition is arranged in the second shell and divides the second shell into an upper chamber and a lower chamber, the upper chamber is used for separating corn kernels and corncobs, and the lower chamber is used for separating corn kernels and impurity. The corn thresher can provide automatic threshing and ensure corn kernel purity, so that packaging in later stage is facilitated.

Owner:靳职雄

Automatic threshing corn thresher

ActiveCN107912152BImprove threshing efficiencyEffective yieldThreshersCircular discAgricultural engineering

Owner:靳职雄

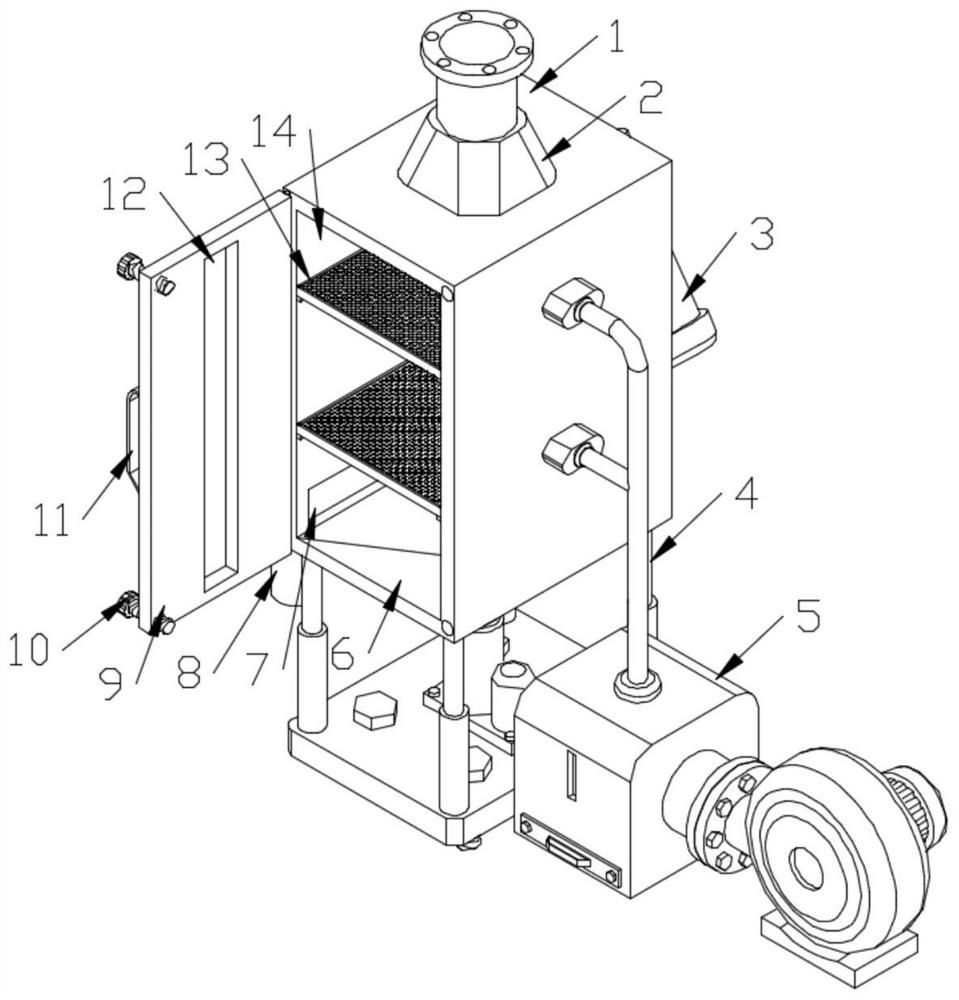

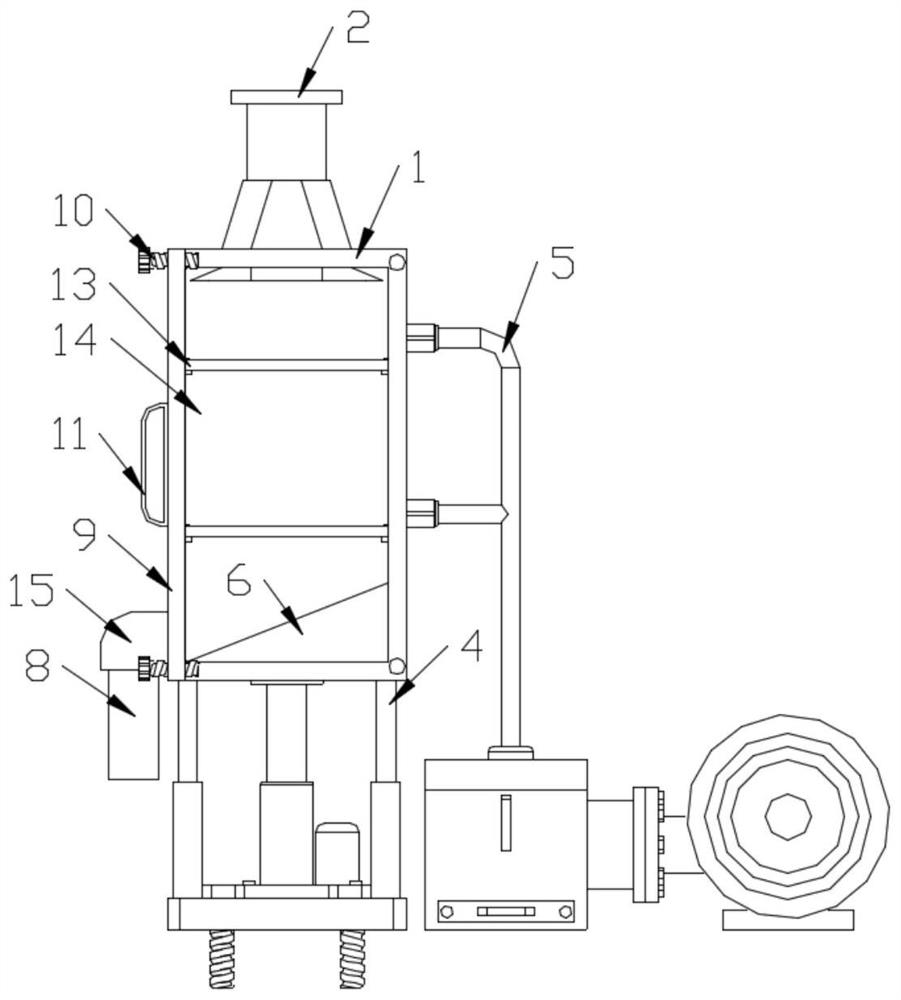

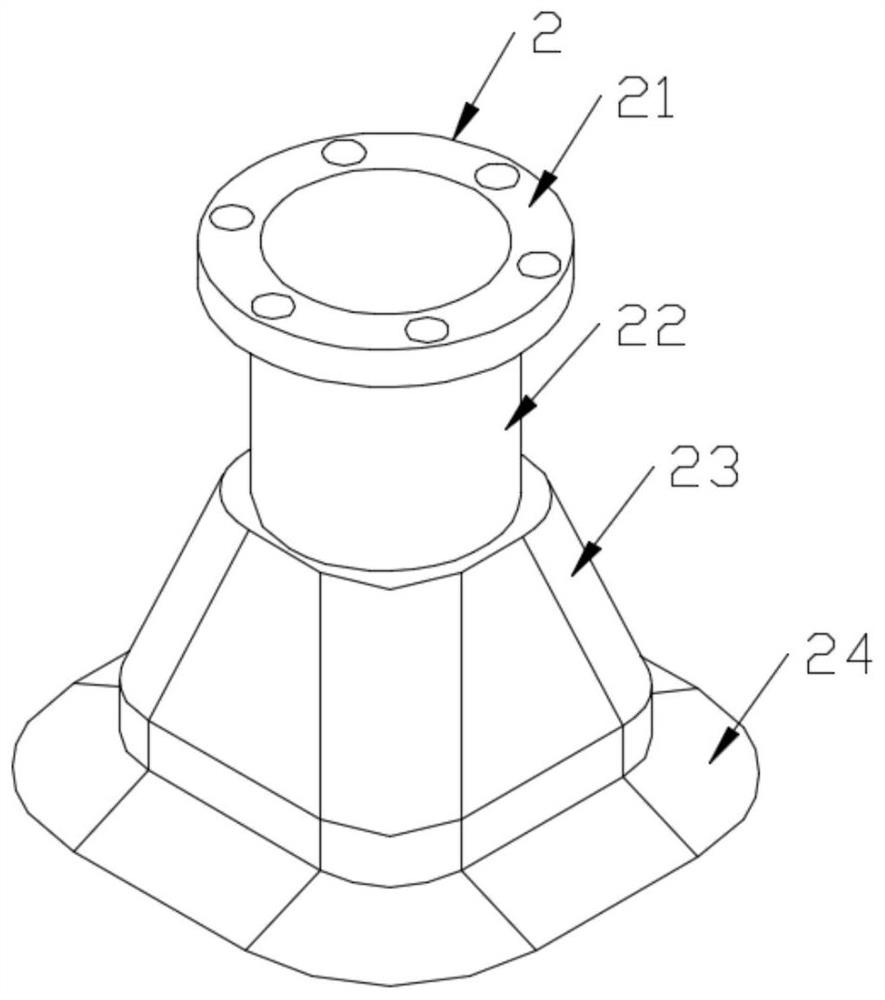

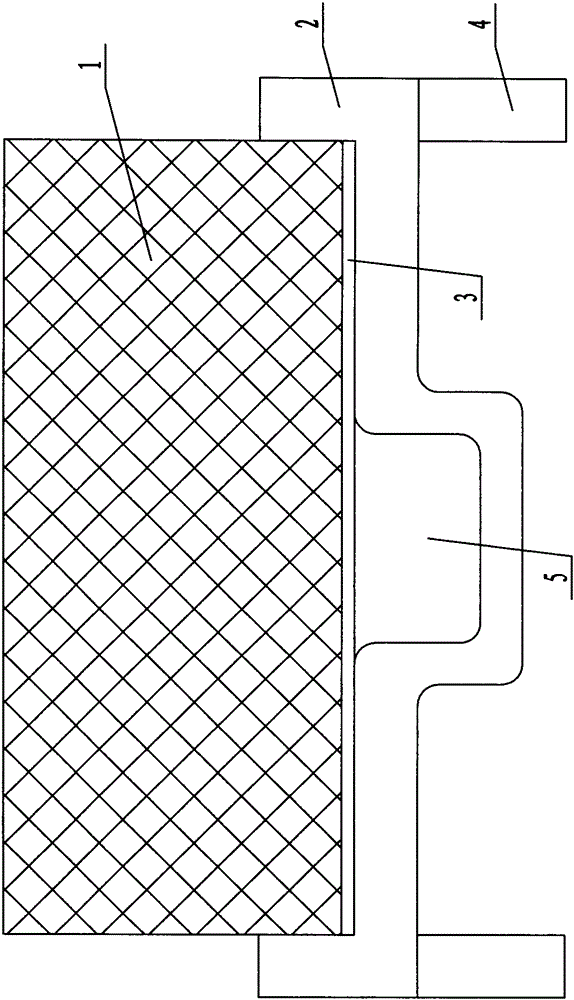

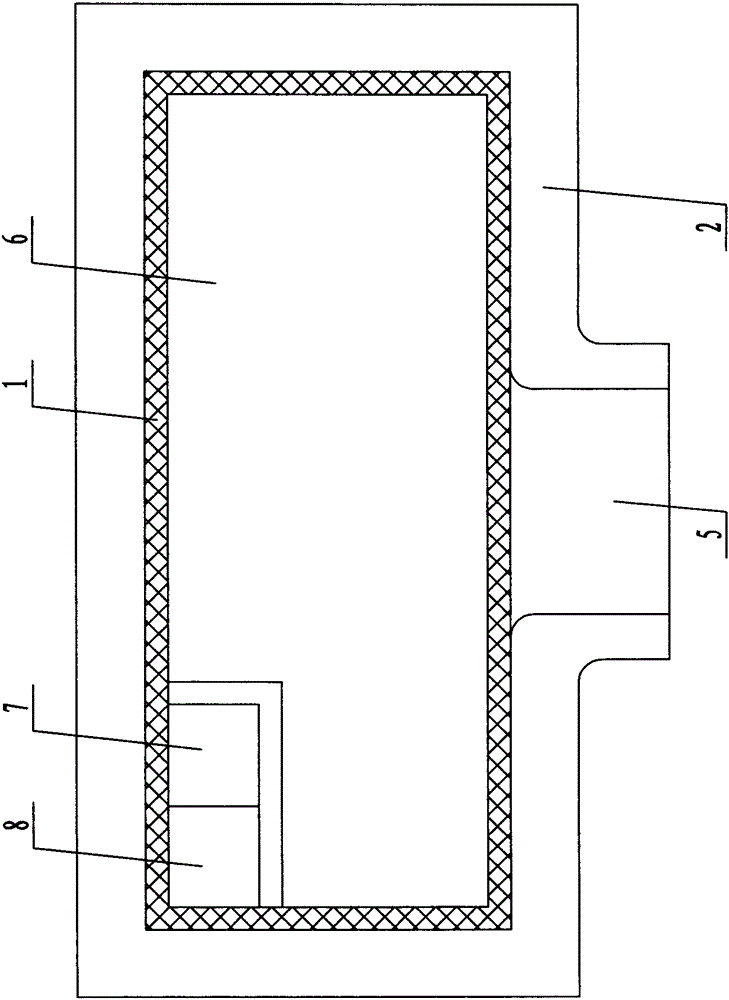

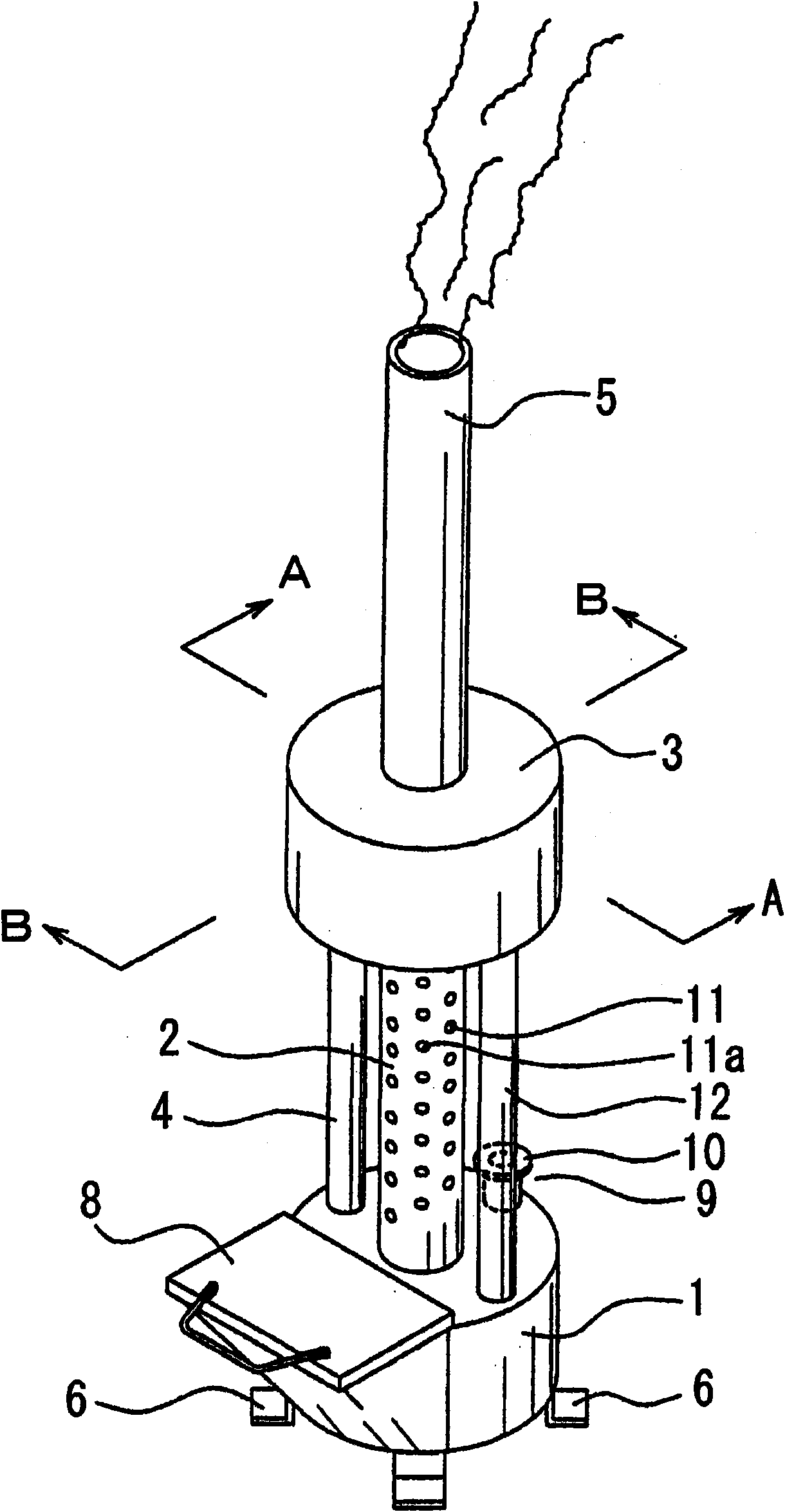

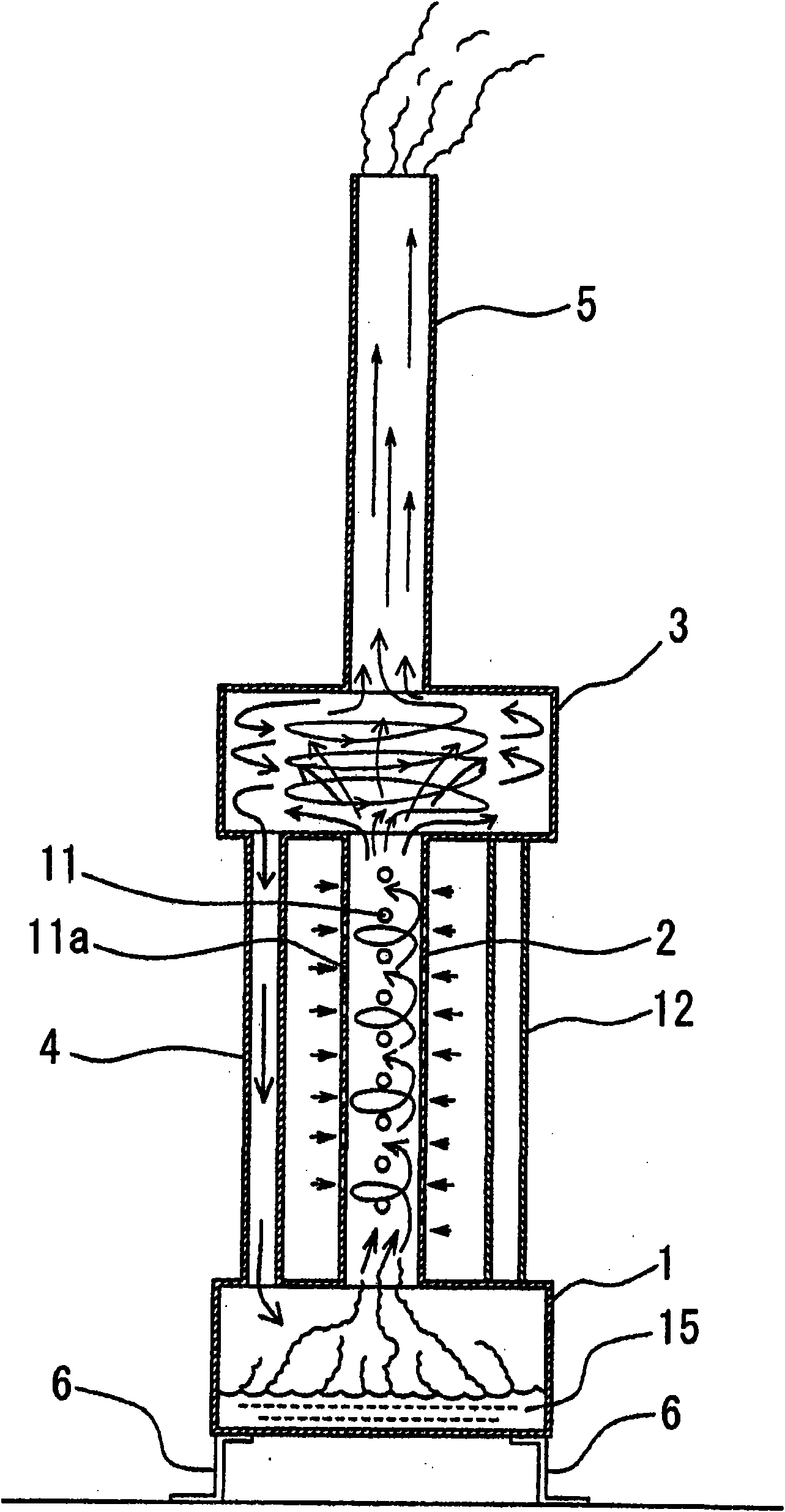

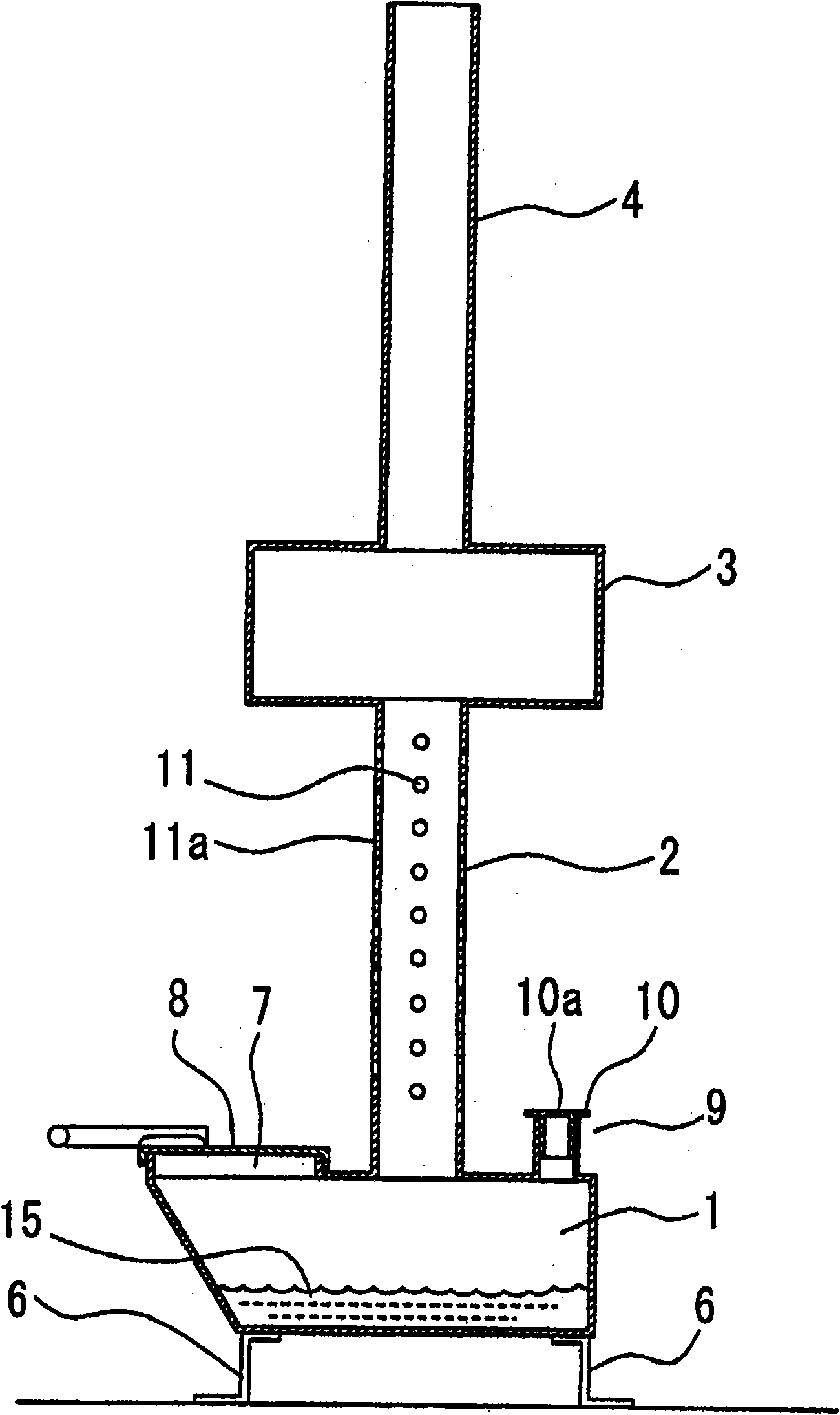

Natural combustion waste oil incinerator

A relatively inexpensive natural combustion waste oil incinerator having a compact and simple arrangement not using the power of an air supply mechanism employing a fan which can combust waste oil completely and suitable as a private facility in small factory or general home or as auxiliary heating of agricultural house or emergency facility at the time of disaster. The natural combustion waste oil incinerator comprises a combustion chamber (1) having a waste oil dumping port and an air inlet (9), a combustion pipe (2) of tubular body having a large number of air suction openings (11, 11a) in the circumferential surface and rising from the central opening in the upper surface of the combustion chamber (1), a circulation chamber (3) installed above the combustion pipe (2) in communication therewith and having a diameter wider than that of the combustion pipe (2), a circulation pipe (4) extending from the base of the circulation chamber (3) to the upper surface of the combustion chamber (1) and interconnecting the circulation chamber (3) and the combustion chamber (1), and an exhaust pipe (5) rising from the central opening in the upper surface of the circulation chamber (3).

Owner:GREEN & ARTS +2

High-efficiency corn thresher

ActiveCN107801493BImprove threshing efficiencyGuaranteed outputThreshersAgricultural engineeringStructural engineering

The invention discloses an efficient corn thresher. The thresher comprises a feeding device and a material shaking device; the feeding device comprises a first shell and a feeding mechanism, and the feeding mechanism comprises a first disc, a second disc and a transition liner; the first disc is arranged at an inlet of the first shell, a first round hole is formed in the first disc, and the seconddisc is arranged at the rear end of the first shell; a second round hole is formed in the second disc, and an annular blade is arranged in the second round hole; the transition liner is arranged between the first round hole and the second round hole; the material shaking device is arranged at the rear end of a feeding tube and comprises a second shell, a mesh screen, a first vibration mechanism and a second vibration mechanism; a partition plate is arranged in the second shell and divides the second shell into an upper chamber and a lower chamber, the upper chamber is used for separating cornkernels with corncob, and the lower chamber is used for separating the corn kernels with impurities; a drying device is arranged at the bottom of the partition plate. Accordingly, threshing of multiple pieces of corn can be conducted simultaneously, and the corn threshing efficiency is improved.

Owner:何亮

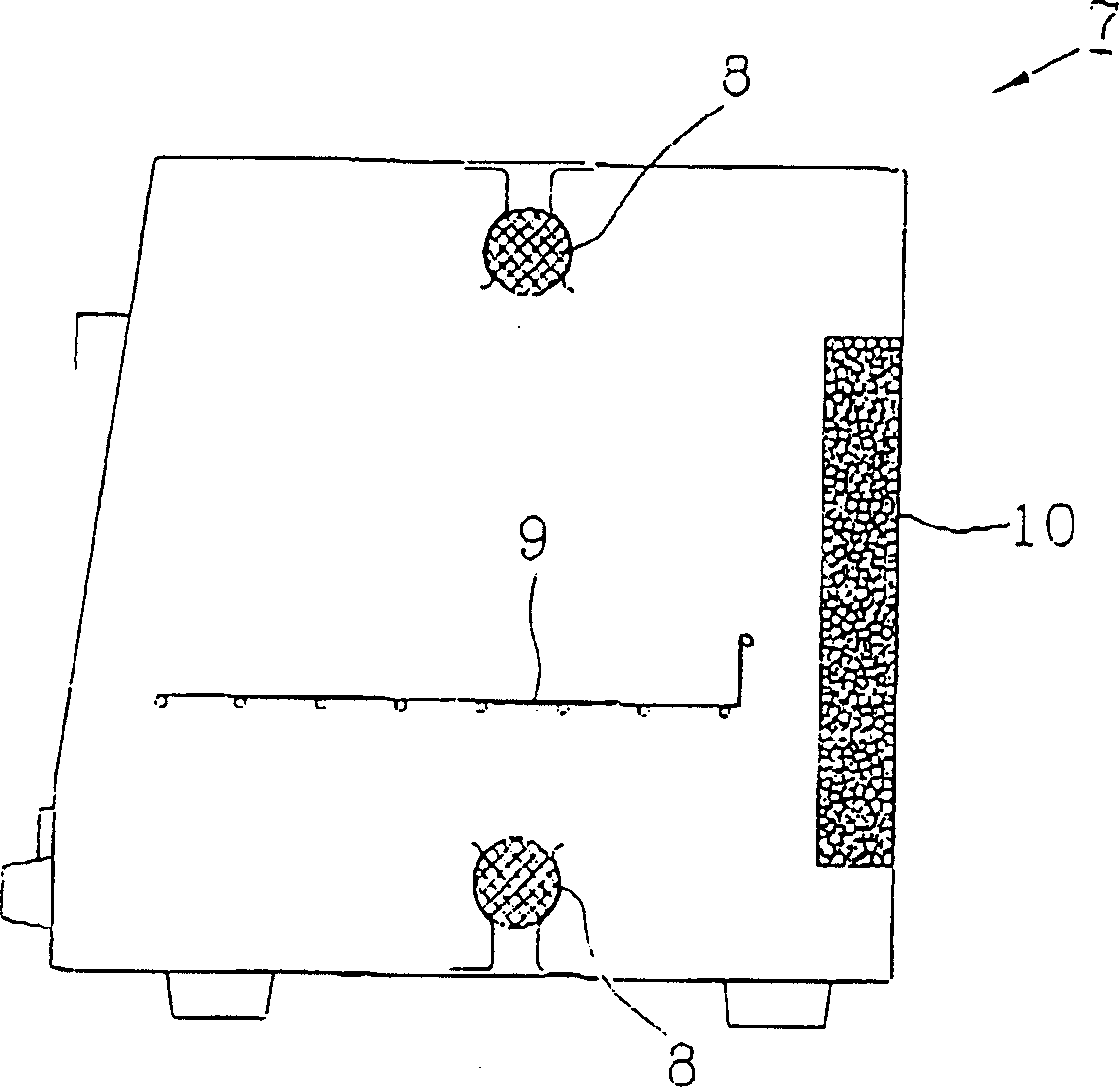

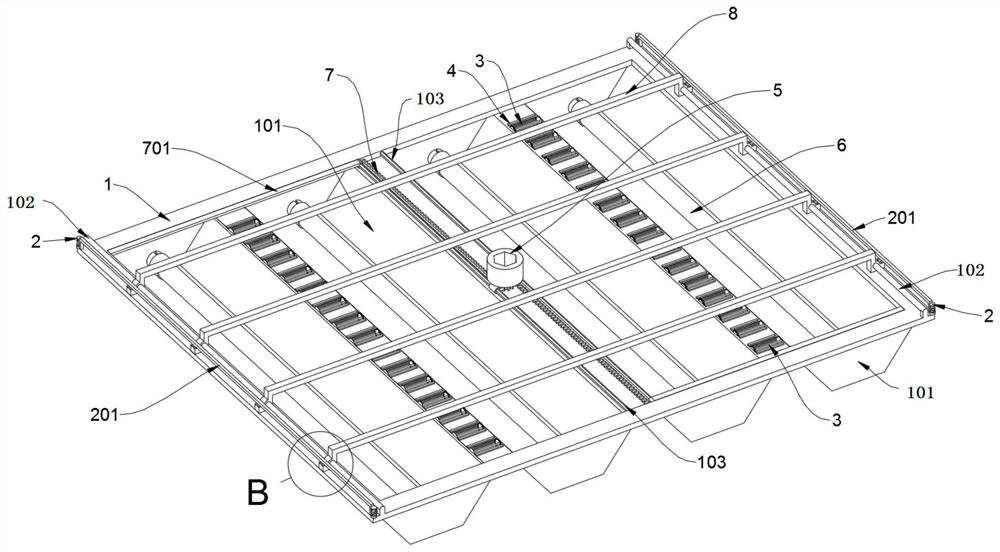

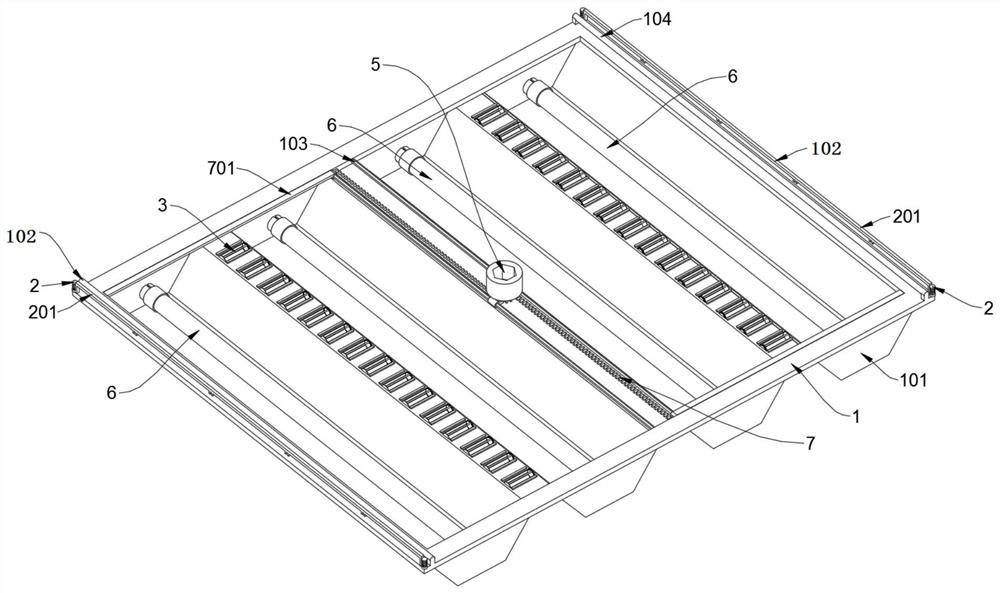

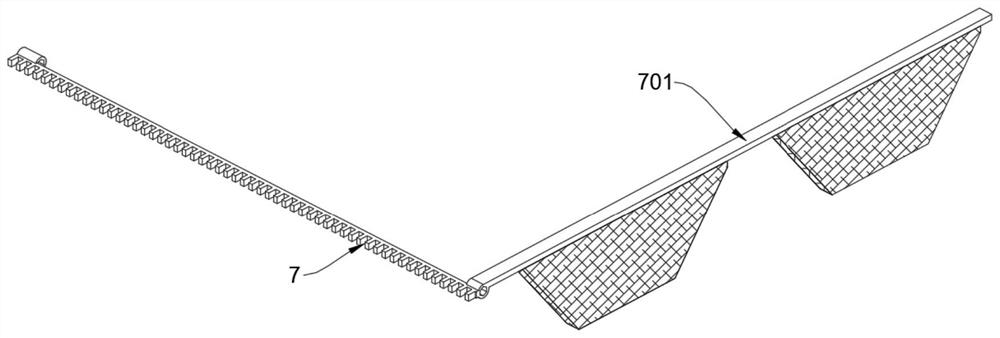

Air guiding structure of light steel frame for constructional engineering

ActiveCN112139083AEfficient and convenient cleaning operationAvoid safety hazardsDispersed particle filtrationTransportation and packagingOpticsSteel frame

The invention discloses an air guiding structure of a light steel frame for constructional engineering, relates to the technical field of building light steel frames, and solves the problems that according to an existing air guiding structure, a user needs to climb high and manually output force to sequentially sweep and clean a filter screen, a lampshade and other components, operation is tediousand inconvenient, and climbing operation has certain potential safety hazards. The air guiding structure of the light steel frame for the constructional engineering comprises a main body frame, the main body frame comprises trapezoidal lampshades and hexagonal prism rods, the whole main body frame is of a square structure, four trapezoidal lampshades are arranged in the main body frame at equal intervals, and a long strip plate is welded and blocked in each of three spaced long strips among the four trapezoidal lampshades; and a row of rectangular vent holes are arranged on each of the threelong strip plates, and a filter roller is rotationally inserted into each of the two rows of rectangular vent holes. In the rotating process of the filter roller, bristles on brush plates on the frontside and the rear side of the filter roller can sweep and clean a metal filter screen on the filter roller, so that the cleaning operation of the filter roller is efficient and convenient.

Owner:安徽嘉玮建设有限公司

ABS resin material with self-cleaned surface and preparation method thereof

The invention provides an acrylonitrile-butadiene-styrene (ABS) resin material with a self-cleaned surface and a preparation method thereof. The ABS resin material consists of the following raw materials in percentage by mass: 0.1 to 5 percent of micron and nanometer aluminum powder, and 95 to 99.9 percent of ABS particles. Pits with micron and nanometer structures can be formed on the surface ofan ABS sheet, and partial air is left in the pits to ensure that liquid drops fail to completely fill into the pits because sizes of the pits are smaller than those of the liquid drops, so that the ABS resin material has hydrophobic property; moreover, the micron and nanometer aluminum powder is used as a template, diluted hydrochloric acid is used as a dissolving agent, and raw materials are readily available; and a manufacturing process is simple, the operation is simple and convenient, the investment is low, and the operation cost is low.

Owner:KUNMING UNIV OF SCI & TECH

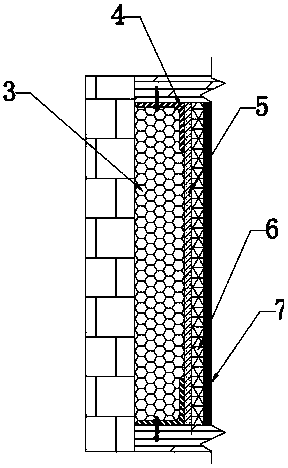

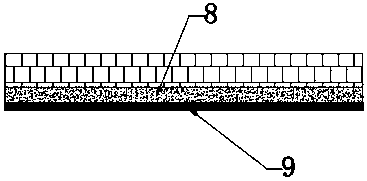

Double-layer Fire Door Gap Structure and Its Construction Technology

ActiveCN106761172BEffect of fire protectionAvoid enteringFireproof doorsJoints tightening/coveringEngineeringFire retardant

The invention discloses a double-deck fireproof door crack structure and a construction process thereof. Particularly, the construction process of the double-deck fireproof door crack structure comprises the following steps that S1, corner clips are fixedly mounted at the four corners of the crack correspondingly; S2, a fire retardant cotton layer with the width the same as that of the crack is filled between the upper and lower corner clips on the left side as well as between the upper and lower corner clips on the right side; S3, a gypsum board is mounted on each fire retardant cotton layer; S4, three putty layers are coated on each gypsum board sequentially; S5, three decoration material layers are coated on every three adjacent putty layers sequentially; and S6, after decoration materials are air-dried, concrete is blended and pasted into transverse crack bodies in the crack, and finally ceramic tiles or coating materials are pasted on concrete layers, so that the outer end face of the crack is located in the same plane as the end face of an outer layer door frame or the end face of an inner layer door frame. The obtained construction process of the double-deck fireproof door crack structure is easy to operate, and the constructed double-deck fireproof door crack structure has the advantages of being firm in structure, attractive in appearance, and good in fireproof performance.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Liquid leakage monitoring equipment for bagged liquid food package

InactiveCN113022994AAvoid pollutionPlay the role of leak reminderPackaging automatic controlEngineeringMechanical engineering

The invention relates to the technical field of automatic packaging, in particular to liquid leakage monitoring equipment for bagged liquid food package. The equipment comprises a first bracket and a second bracket fixedly connected with the first bracket in parallel, the bottom end of the outer surface of the first bracket is fixedly connected with a positive plate, and the bottom end of the outer surface of the second bracket is fixedly connected with a negative plate. One end of the positive plate and one end of the negative plate are fixedly connected with first guide plates, one end of each first guide plate is fixedly connected with a conductive wire, one end of each conductive wire is fixedly connected with a second guide plate, the outer surface of the first bracket is movably connected with a supporting plate, and the outer surface of the supporting plate is fixedly connected with a sponge plate. When the second guide plates slidably connected to the two sides of a pressing plate are pushed from connection to separation, the positive plate and the negative plate in the equipment are disconnected, the equipment is not electrified any more, the equipment stops running, sealing is stopped, a large amount of follow-up pollution to packaging bags can be prevented, and the liquid leakage prompting effect can be achieved.

Owner:南京心厨供应链管理有限公司

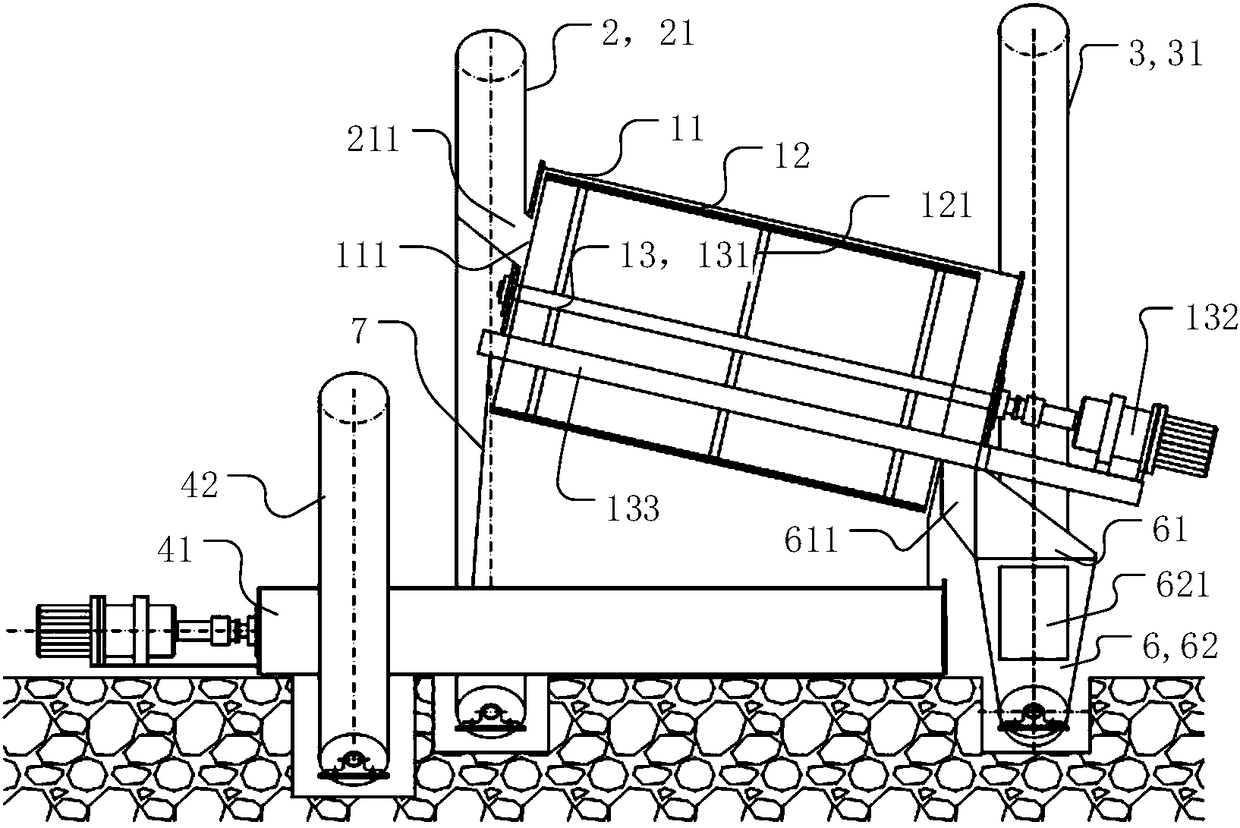

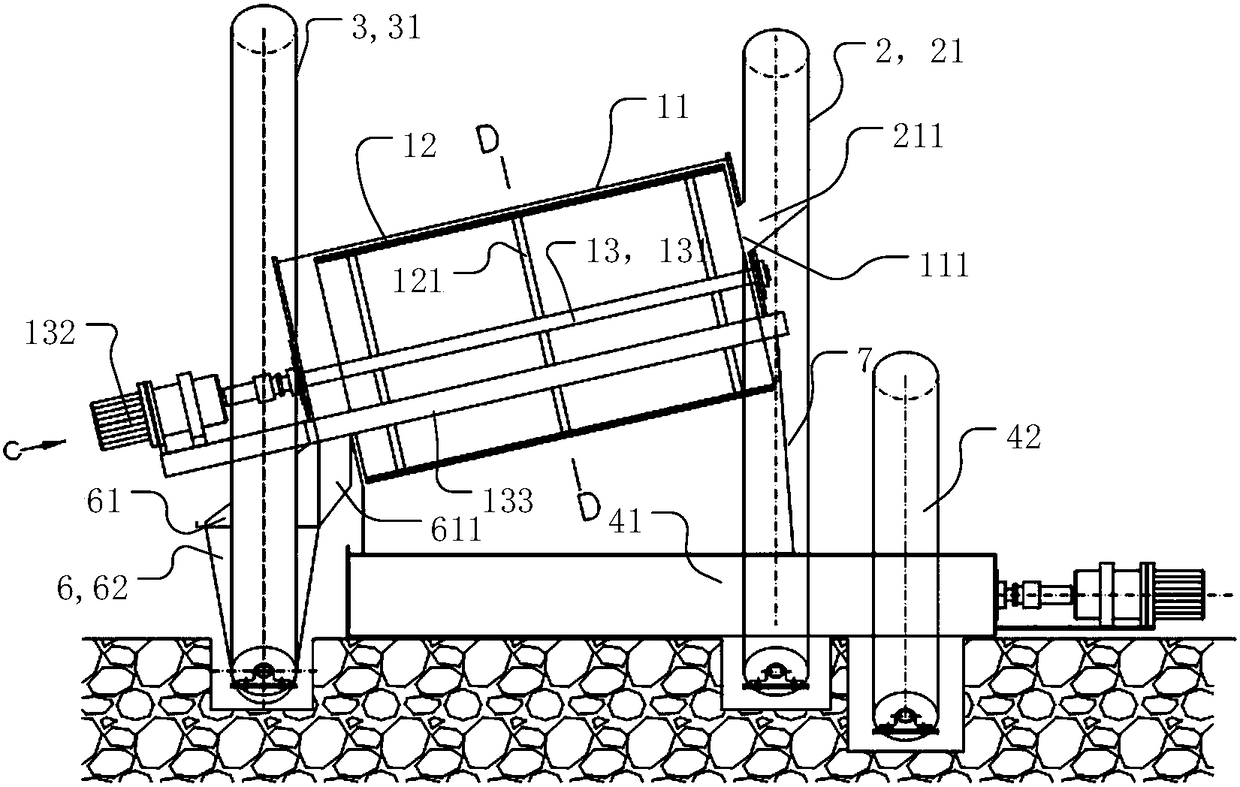

Separation screen module

The invention provides a separation screen module. The separation screen module comprises a separation screen, and a conveying mechanism connected with the separation screen. The separation screen module is characterized in that a first end of the separation screen is connected with a feed spiral conveying mechanism; a second end of the separation screen is connected with a first discharge spiralconveying mechanism; a second discharge spiral conveying mechanism is connected under the separation screen; and the connected places of the separation screen with the feed spiral conveying mechanism,the first discharge spiral conveying mechanism and the second discharge spiral conveying mechanism are all of closed connecting structures. The separation screen module can achieve effective dust prevention and higher automation degree and production efficiency.

Owner:黑龙江如柏科技有限公司

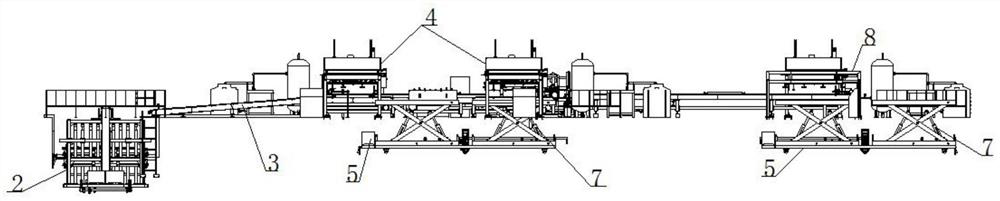

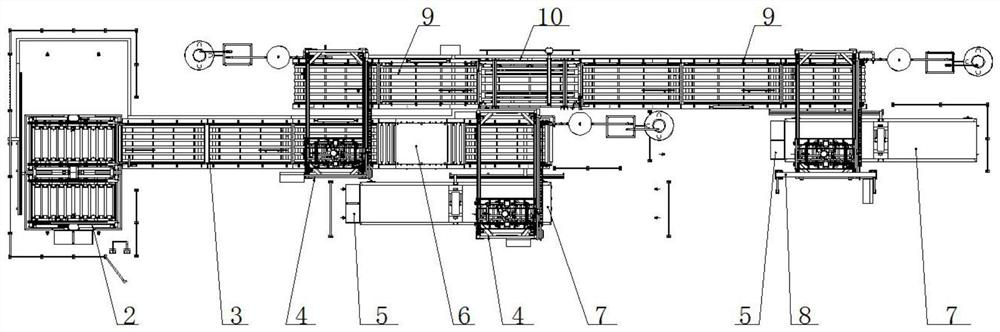

Double-line assembly production line with de-molding function

PendingCN112123526AIncrease productivityImprove practicalityDischarging arrangementAuxillary shaping apparatusManufacturing lineManufacturing engineering

The invention discloses a double-line assembly production line with a de-molding function. The double-line assembly production line comprises a 2.2-meter ferry push car, a plate unloader, a conveyingline A, a dual-station disc sucking machine, a lifter ferry push car, a mold clearing machine, a 5T fork type lifter, a single-side widening leg of the dual-station disc sucking machine, a conveying line B and a plate turnover machine, wherein the plate unloader is arranged at the right side of the 2.2-meter ferry push car; the conveying line A is arranged at the right side of the plate unloader;the dual-station disc sucking machine is arranged on the top of the conveying line A; the mold clearing machine is arranged on the top surface of the conveying line A; the conveying line B is arrangedon the back surface of the conveying line A; and the single-side widening leg of the dual-station disc sucking machine is arranged on the top of the right end of the conveying line B. The double-lineassembly production line with the de-molding function can realize automatically separating product plates from molding boards, is high in non-stop efficiency, can achieve effects of clearing the molding boards, protecting the product plates and the like, is easy to operate, is simple in structure, is high in safety, and is low in manufacturing cost and operation cost.

Owner:青岛美中建材机械有限公司

Building ground polishing device

PendingCN111588308AProtect the bodyReduce spreadGrinding carriagesPolishing machinesElectric machineArchitectural engineering

The invention discloses a building ground polishing device. The device comprises a shell, two or more guide rods are annularly arranged at the upper end of the shell, a movable plate is assembled between the two or more guide rods, the upper ends of the guide rods penetrate through the movable plate and are provided with limiting nuts, the guide rods are sleeved with springs, the springs act between the shell and the movable plate, and a motor is connected to the axis of the upper end of the movable plate through a flange. Kneeling polishing is not needed, meanwhile, the polishing efficiency is high, and dust can be prevented from being scattered all around.

Owner:山东诚祥建设集团股份有限公司

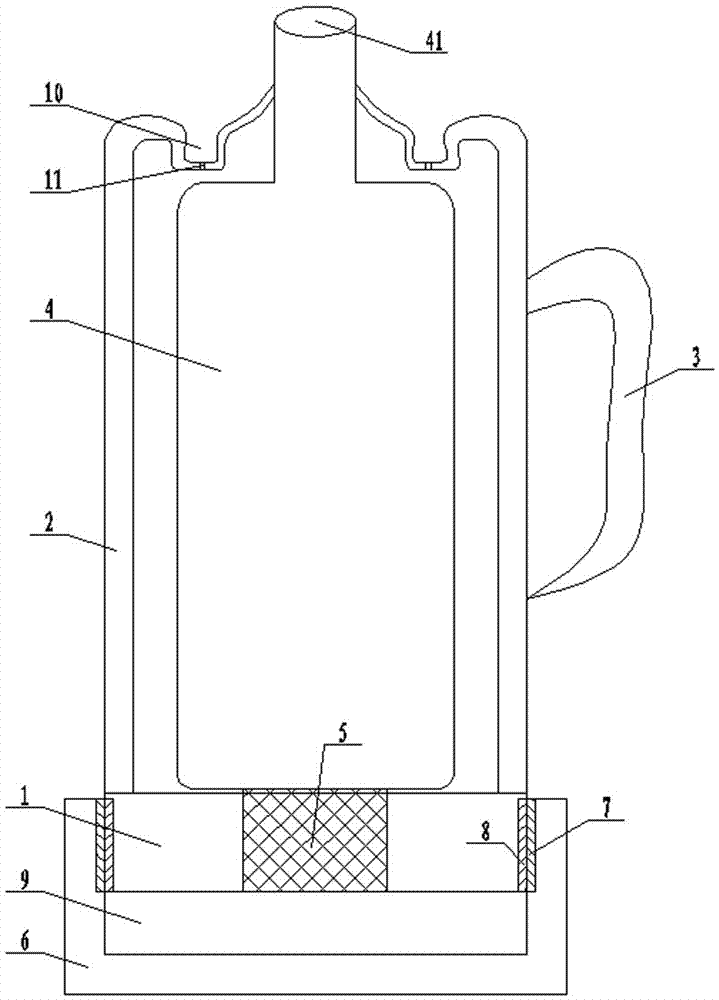

Tea bottle

The invention discloses a tea bottle, which comprises: a base, a tea bottle shell set on the base, a handle set on one side of the tea bottle shell, a vacuum liner set in the tea bottle shell, and a base at the lower end of the vacuum liner. The grid rotation locking plugs that cooperate with each other in the vacuum liner are provided with a water injection port at the upper end of the vacuum liner, and the water injection port extends out of the tea bottle shell, and a water receiving base is provided at the lower end of the tea bottle shell, and the tea bottle External threads are provided on the outside of the lower end of the shell, internal threads that cooperate with the external threads are provided on the inside of the upper end of the water receiving base, a water receiving tank is provided between the water receiving base and the base, and a water receiving tank is provided outside the water injection port. An annular water receiving groove is arranged on the outer shell of the tea bottle, and a plurality of flow holes communicating with the interior of the tea bottle outer shell are uniformly arranged at the bottom of the annular water receiving groove.

Owner:华茂东

Automatic toilet cleaners and self-cleaning toilets including automatic toilet cleaners

ActiveCN112302126BKeep and manage cleanlinessLess Cleaning HassleWater closetsFlushing devicesTap waterMechanical engineering

Automatic toilet cleaners and self-cleaning toilets including automatic toilet cleaners are provided. In one aspect of the present disclosure, an automatic toilet cleaner is provided. The automatic toilet cleaner may include: a cleaning solution tank configured to contain the cleaning solution; a spray tube configured to connect to the cleaning solution tank and spray the cleaning solution onto an end of the toilet supporting the toilet seat unit; and a cleaning solution tank configured to collect a portion of the sprayed cleaning solution that flows out of the toilet. In this case, the cleaning solution tank may be configured to be supplied with tap water through connection with a water supply pipe, and to supply the cleaning solution to the nozzle.

Owner:魏敬一

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com