Electromagnetic type dynamic plate load test detecting device and method

A technology of plate load and detection equipment, which is applied in the direction of applying repeated force/pulsation force to test material strength, foundation structure test, construction, etc., and can solve the dynamic response properties of the foundation that cannot respond well to dynamic loads, and size effects. Errors, loads that are difficult to reach the value, etc., to eliminate the effect of size effect, improve the impact speed and impact energy, easy to carry and use quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

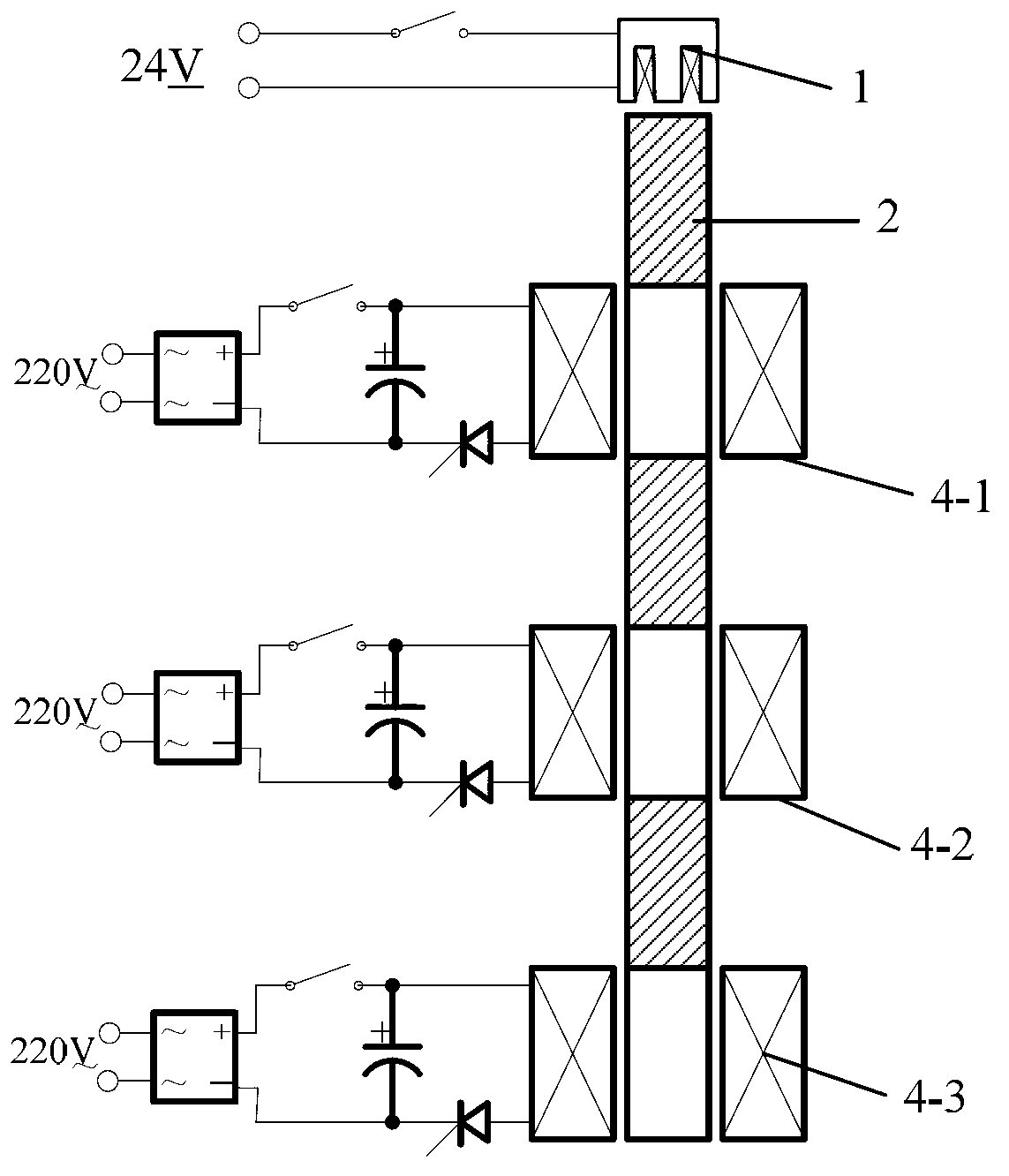

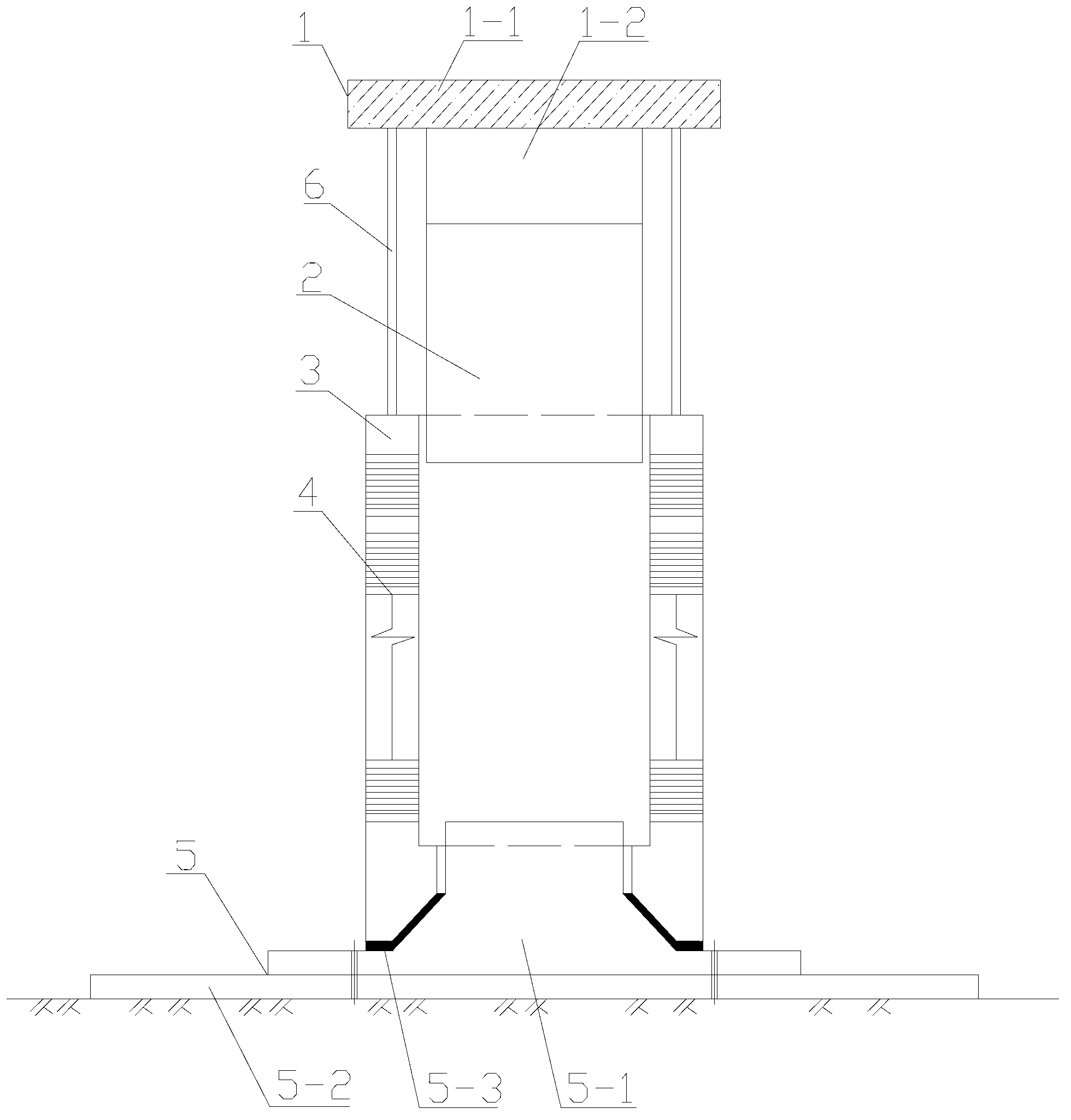

[0035] In this embodiment, a kind of electromagnetic dynamic plate load test detection equipment, such as figure 1 or figure 2 As shown, it includes an electromagnet assembly 1, an impact rod 2, an outer sleeve 3, an electromagnetic acceleration coil 4 and an impact seat plate assembly 5. The electromagnet assembly is arranged above the outer sleeve, the impact rod is arranged in the outer sleeve, and the impact seat The board assembly is arranged under the outer sleeve, and the inner wall of the outer sleeve is provided with multi-stage electromagnetic acceleration coils, and the electromagnetic acceleration coils at each level are respectively connected to the circuit control system; for example figure 2 As shown, the impact seat plate assembly 5 includes an impact seat 5-1 and a pressure-bearing plate 5-2, and the pressure-bearing plate is fixed on the bottom of the impact seat; Inside the outer sleeve.

[0036] In order to reduce the collision or friction between the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com