Mass-concrete cooling water recycling device and method

A large-volume concrete and cooling water technology, which is applied in the direction of gas/liquid distribution and storage, piping systems, mechanical equipment, etc., can solve the problems of low utilization rate of cooling water, waste, and increased drainage pressure of foundation pit pumping stations, etc., to achieve Reduce water resources and power consumption, improve actual efficiency, and reduce the effect of inlet water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

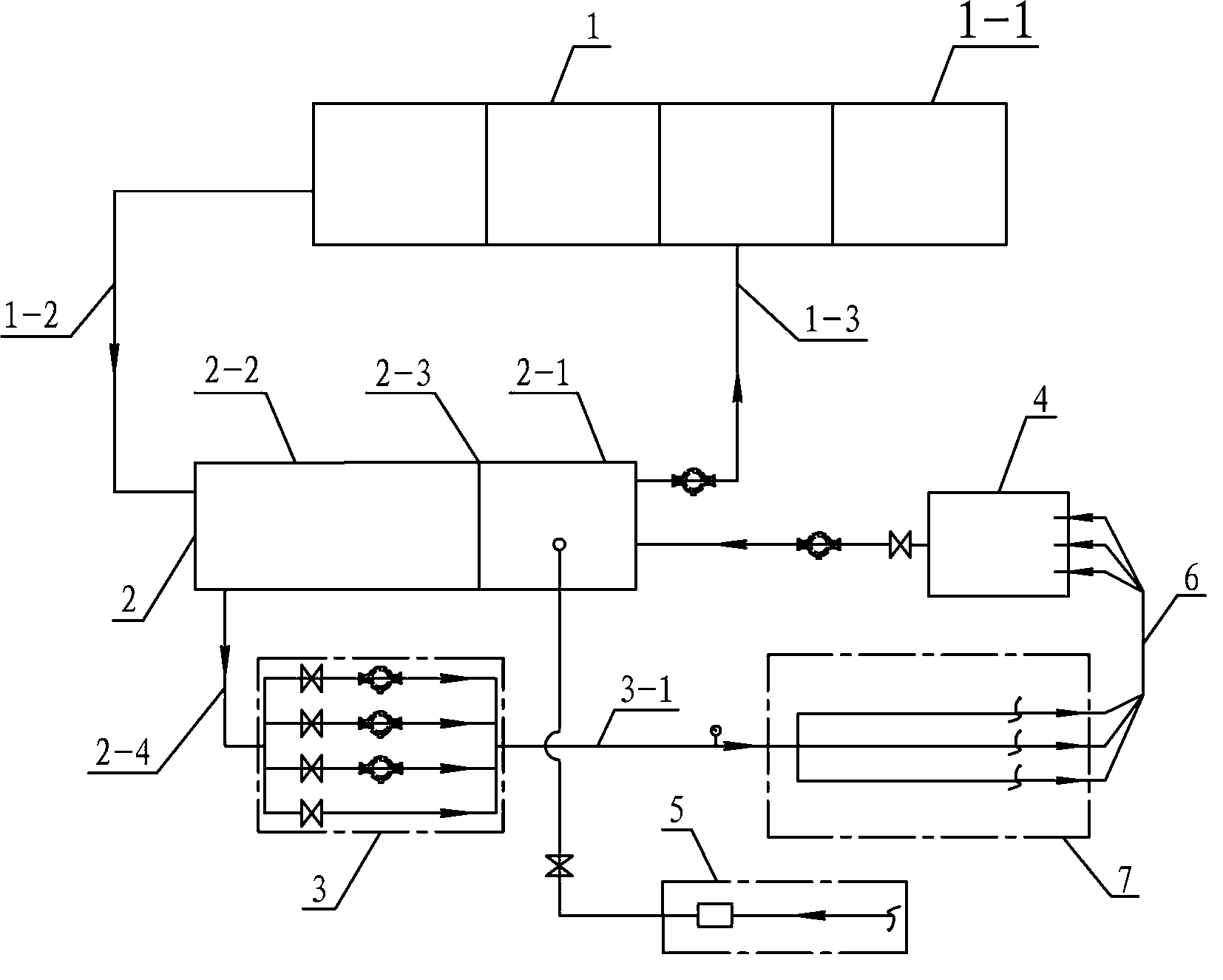

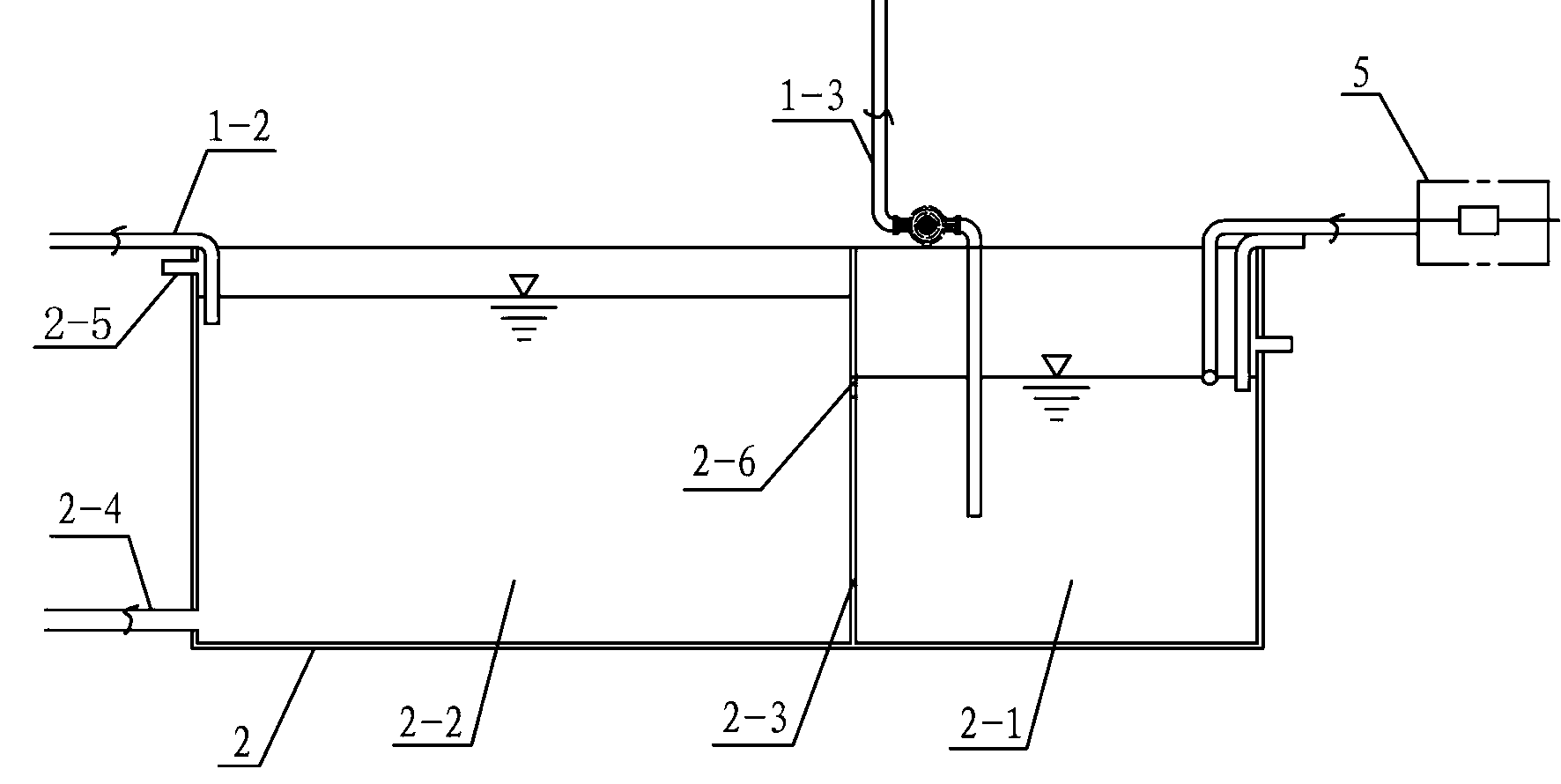

[0028] Such as Figure 1~2 As shown, a large-volume concrete cooling water reuse device includes a refrigeration system 1, a circulating water tank 2, a cold water delivery system 3, a return water collection tank 4, and a water replenishment system 5. The refrigeration system 1 is connected to the circulating water tank through the outlet pipe 1-2 2 is connected, the circulating water tank 2 is connected with the cold water delivery system 3 through the water inlet pipe 2-4, the cold water delivery system 3 is connected with the cooling pipe of the mass concrete cooling zone 7 through the water outlet pipe 3-1, and the cooling pipe is connected with the return water through the return pipe 6 The water collection tanks 4 communicate with each other, and the return water collection tank 4 sends the collected cooling return water to the circulating water tank 2 through a water pump.

[0029] The circulating water tank 2 is composed of a mixed water tank 2-1 and a finished water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com