A shift gear driver of a flywheel synchronous transmission

A kind of transmission and synchronous technology, which is applied in transmission devices, gear transmission devices, clutches, etc., can solve the problems of cumbersome manufacturing of transmission structures, and achieve the effects of simple and reliable pre-synchronization, simple manufacturing, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

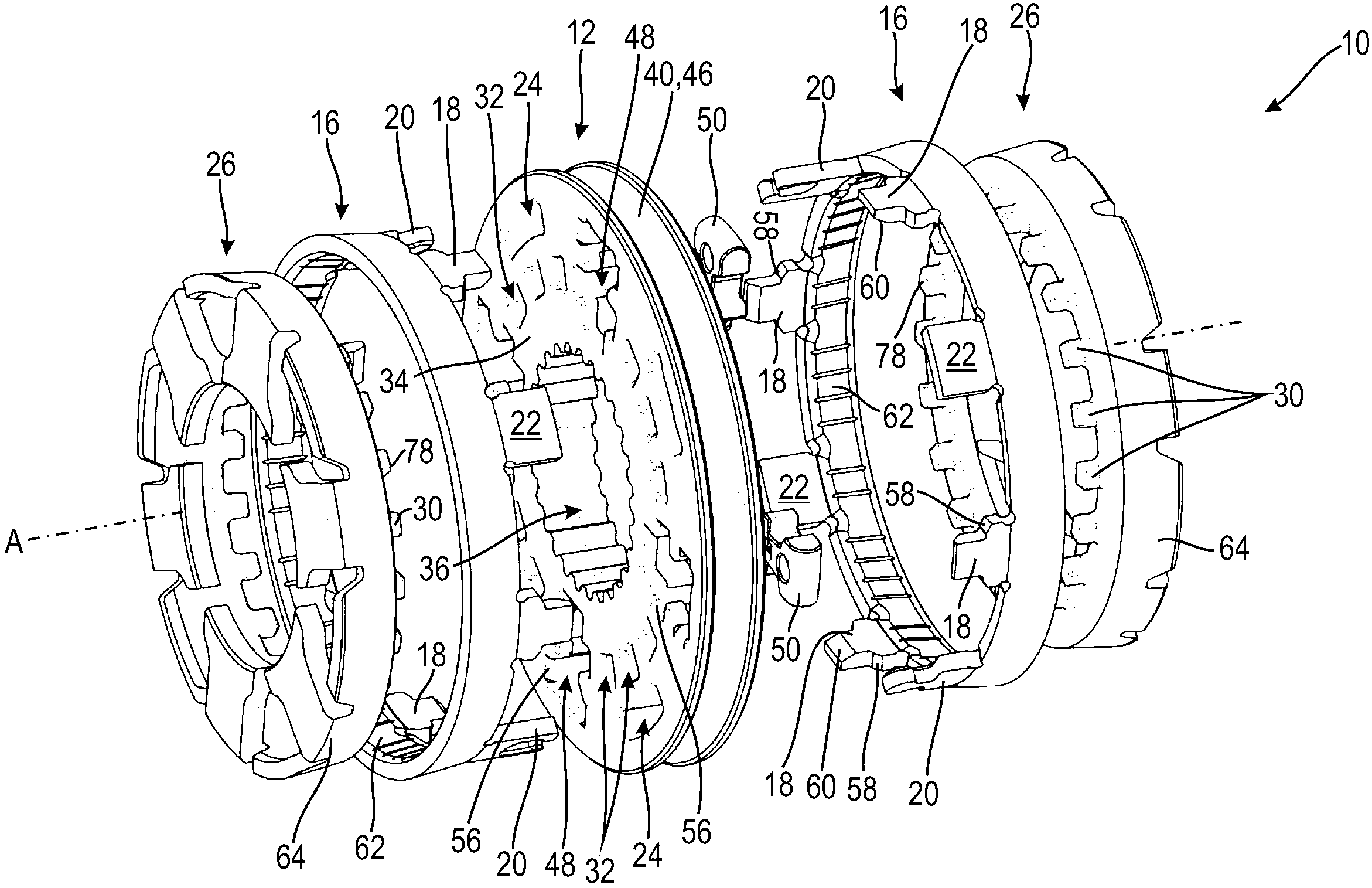

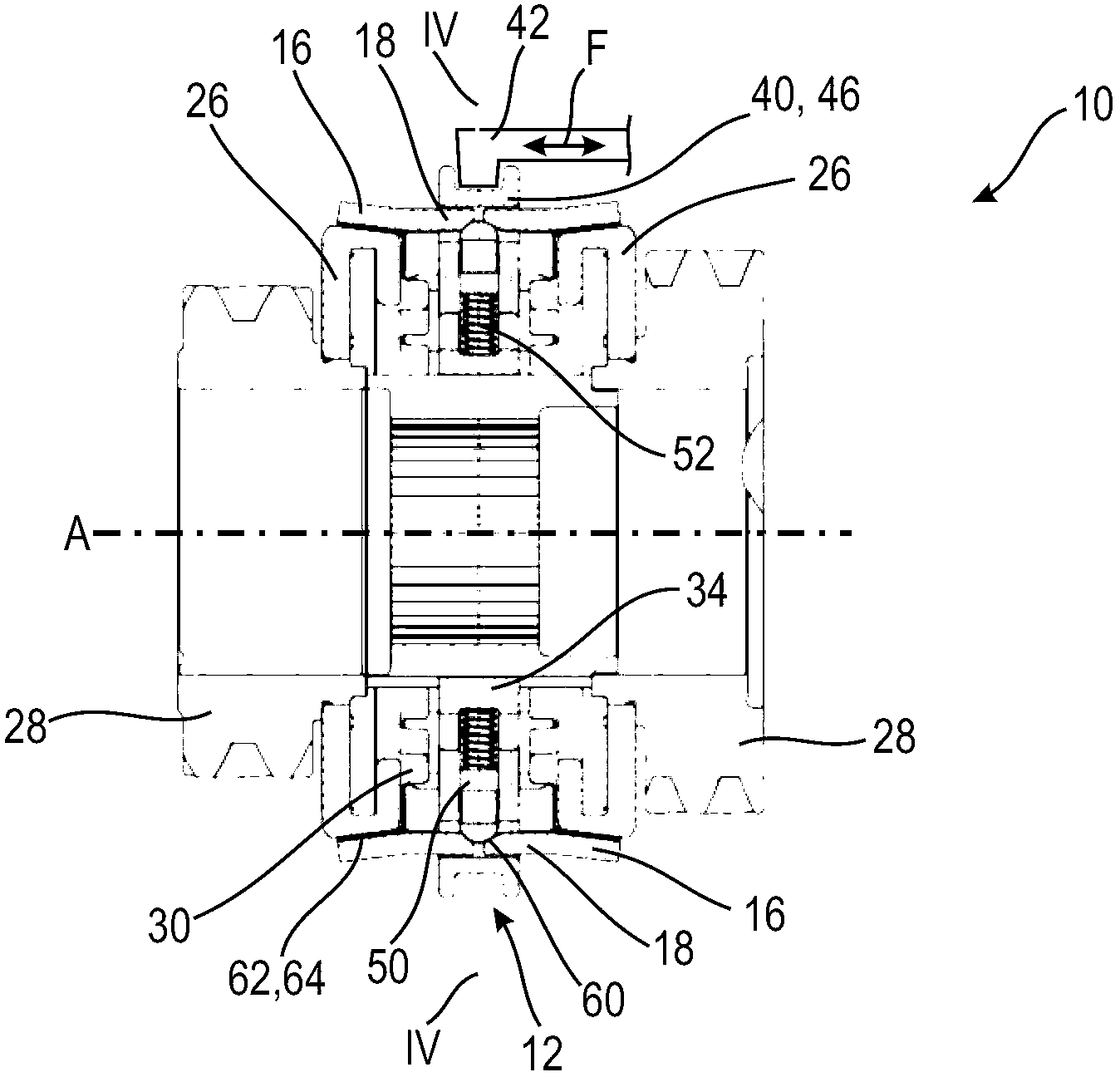

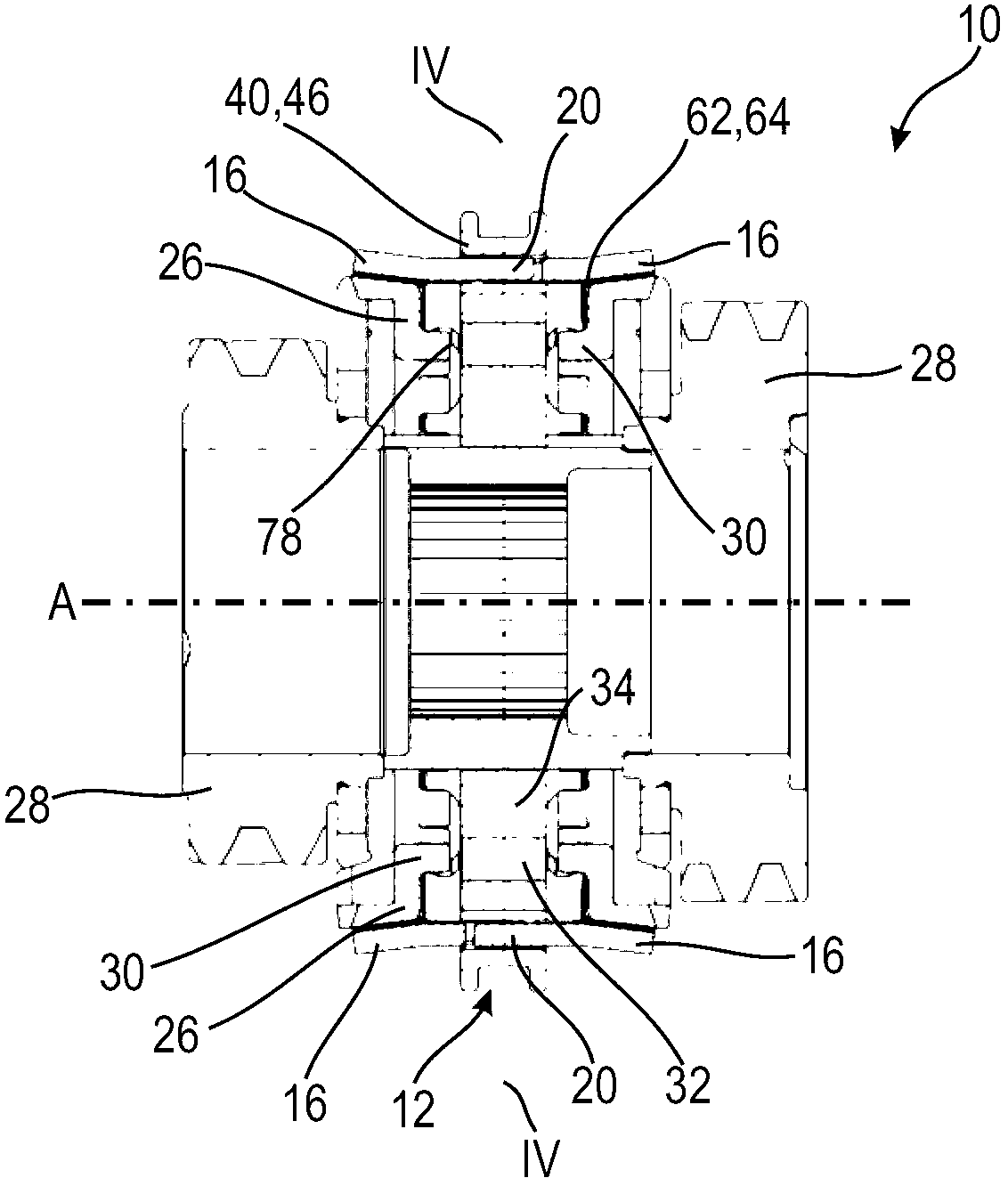

[0036] Figures 1 to 6 A first embodiment of an inertia-synchronous transmission 10 for a motor vehicle is shown, said transmission having an axially displaceable shift drive 12 according to the first embodiment, arranged on axially opposite sides of the shift drive 12 The two clutch bodies 26 on the side, and the two friction rings 16 that are also arranged on both axial sides of the shifting transmission 12 and coupled with the shifting transmission 12 along the circumferential direction 14, the clutch bodies can be arranged along the circumferential direction 14 Coupled in a rotationally fixed manner to the shifting drive 12 , the friction ring has axial projections 18 , 20 , 22 which can protrude into synchronizing recesses 24 of the shifting drive 12 .

[0037] Clutch body 26 is independent, but is respectively fixedly with the follower wheel 28 (referring to figure 2 and 3 ) connected components. In particular, the clutch body 26 is a profiled sheet metal part and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com