LED lamp bulb and manufacturing method thereof

A technology of LED light bulbs and manufacturing methods, which is applied in the direction of lampshades, components of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems of reducing the damage probability of driving power supply components, etc., to reduce the damage probability, reduce equipment costs, increase The effect of holding space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

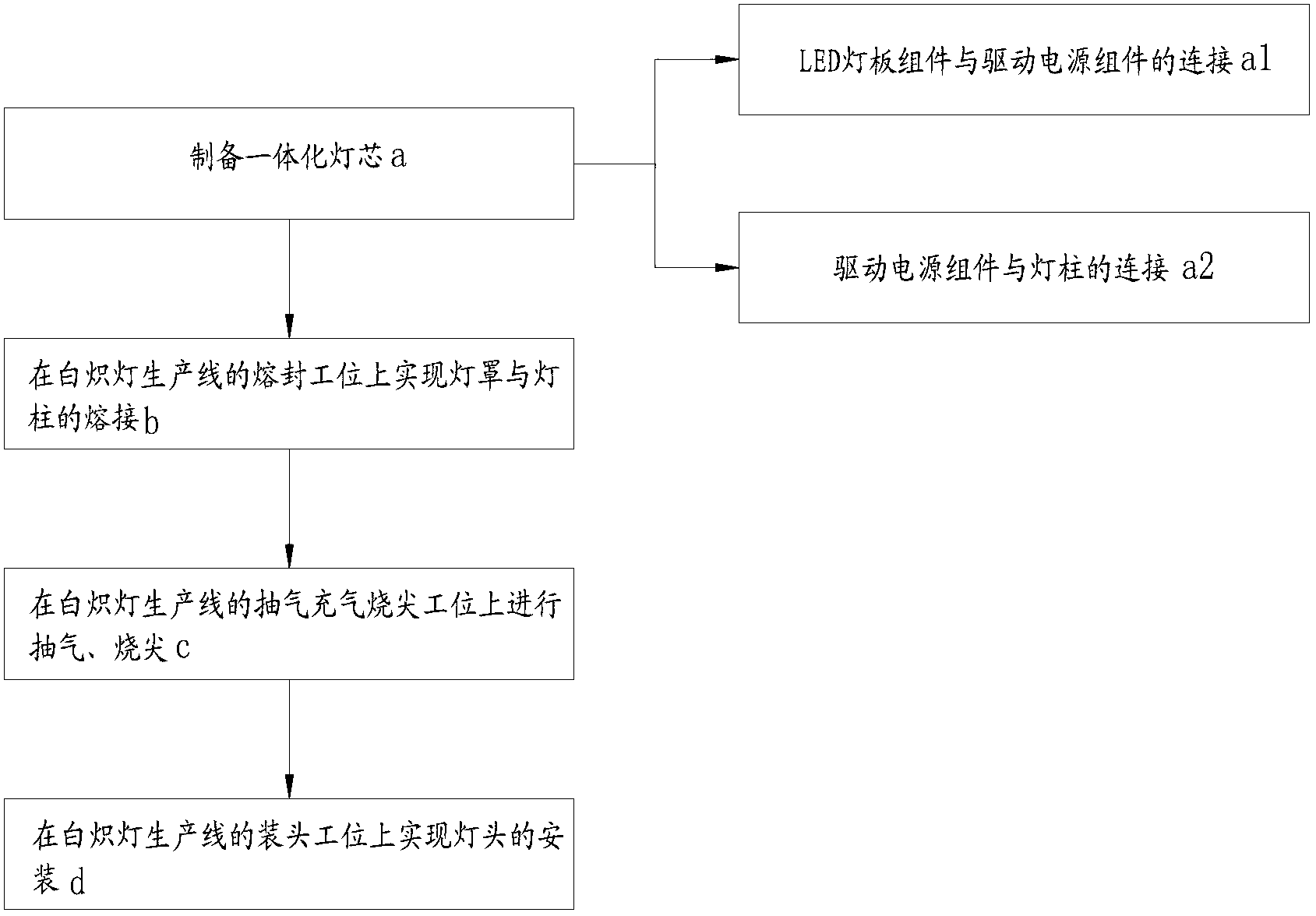

[0044] Such as figure 1 , 2 , 3, 4, 5, and 6 show the first embodiment of a method for making an LED light bulb of the present invention, comprising the following steps:

[0045] (a) preparing an integrated wick, including step (a1) and step (a2); wherein,

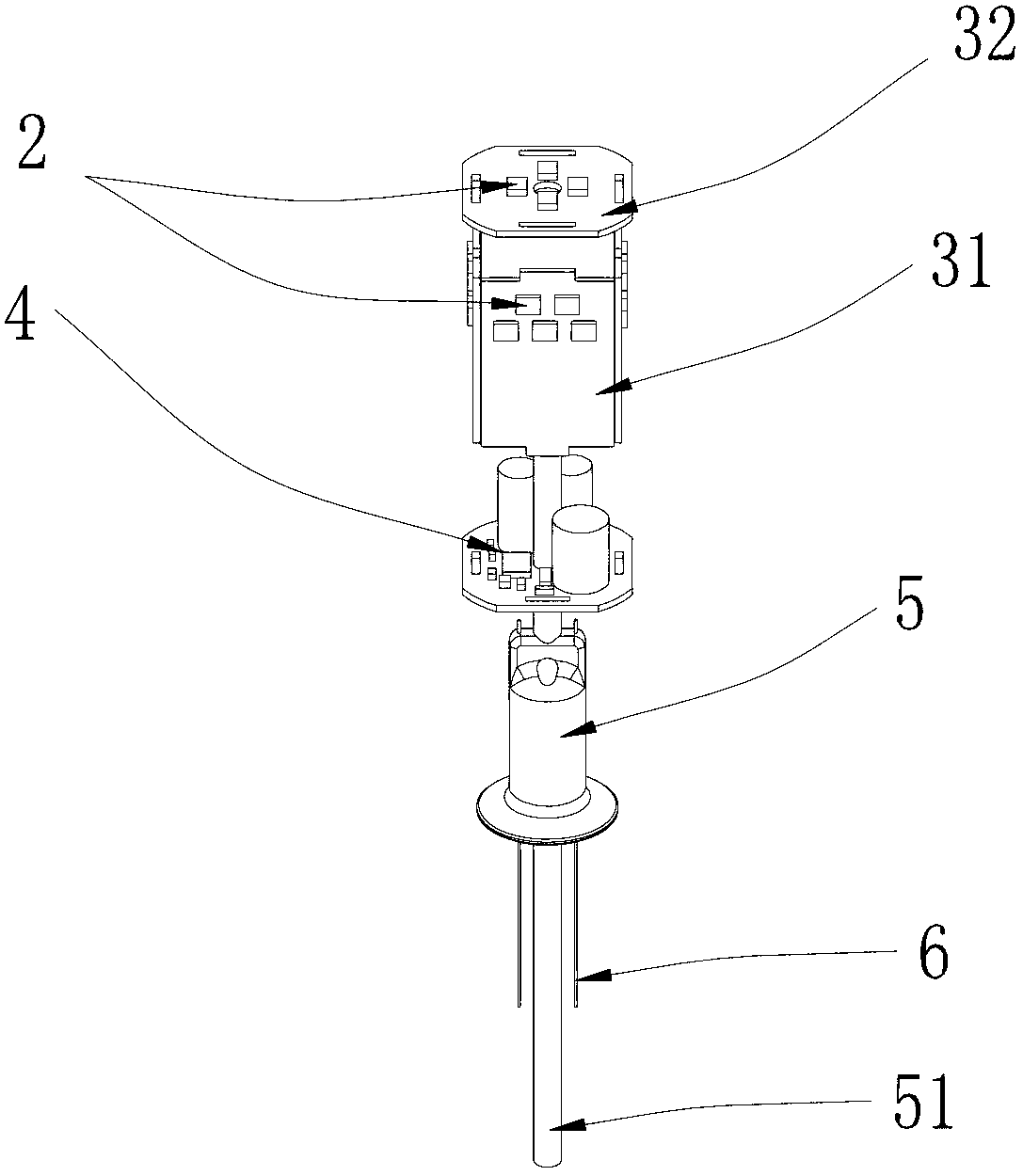

[0046] (a1) Connection of the LED light source component and the driving power component 4; fixing and electrically connecting the LED light source component to the driving power component 4;

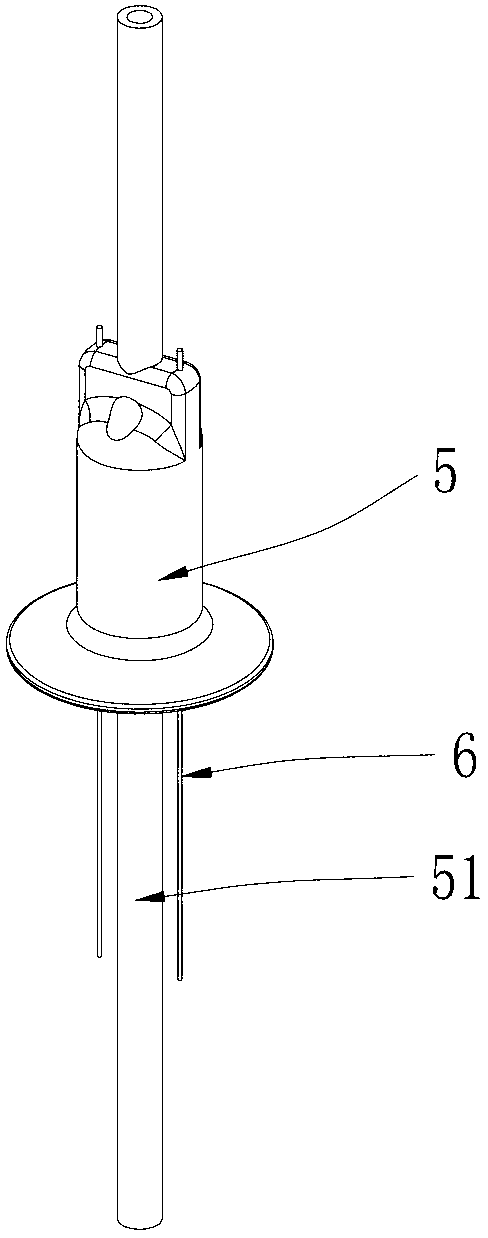

[0047] Such as image 3 As shown, the LED light source assembly includes several heat dissipation light source boards 31 and heat dissipation top boards 32, the LED light sources 2 are arranged on the heat dissipation light source boards 31 and the heat dissipation top boards 32, and the heat dissipation light source boards 31 and the heat dissipation top boards 32 can adopt Made of aluminum base material or heat conduction plate, and has both heat dissipation and bearing functions; in step (a1), each heat dissipation light sourc...

Embodiment 2

[0068] The difference between the second embodiment of the manufacturing method of the LED light bulb of the present invention and the first embodiment is only in step (a1), in step (a1), the LED light source assembly includes a small heat dissipation plate 82 and two heat dissipation lamp plates 81 , the two heat dissipation lamp boards 81 and the heat dissipation small board 82 are provided with LED light sources 2; in step (a1), the two heat dissipation lamp boards 81 are arranged on the driving power supply assembly 4 in a cross manner and form a cross-shaped section The support column, the heat dissipation small plate 82 is installed on the upper end surface of the support column to form a support lamp holder; wherein, the heat dissipation small plate 82 is fixed and electrically connected to the two heat dissipation lamp boards 81 by welding, the support lamp holder and the driving power supply assembly The output end of 4 is electrically connected.

[0069] Such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com