Moisture-proof and wear-resistant corrugated paper and production method thereof

A technology for corrugated paper and corrugated paper, which is applied in the field of papermaking, can solve problems such as affecting commodities, falling out, and commodity damage, and achieves the effects of reducing moisture absorption, preventing losses, and preventing penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

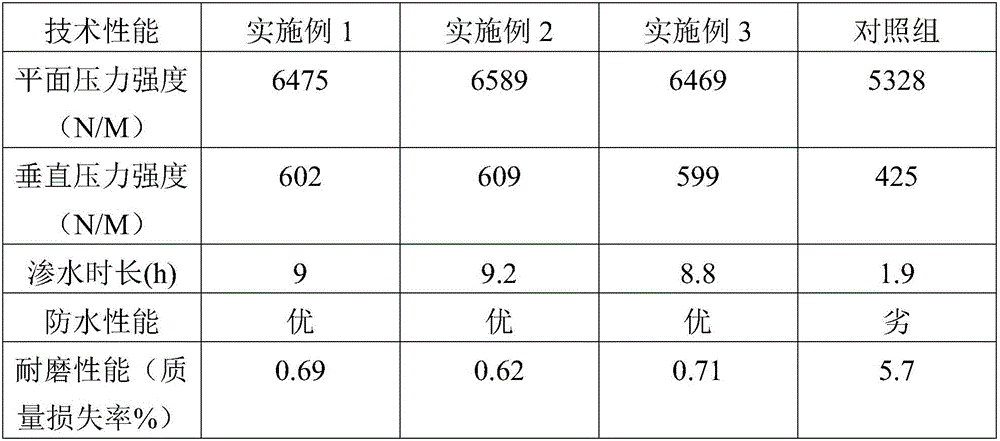

Embodiment 1

[0025] A moisture-proof and wear-resistant corrugated paper, including the following raw materials in various mass fractions:

[0026] 200 parts of waste paper, 50 parts of non-woven fabric, 60 parts of super absorbent resin, 70 parts of polyester staple fiber, 30 parts of oyster shell powder, 15 parts of dextrin, 1.2 parts of borax, 25 parts of paraffin emulsion, 3 parts of silicon dioxide, 3 parts of corundum powder, 8 parts of talc powder, 3 parts of aluminum oxide, 30 parts of oxidized starch, 2 parts of allyloxy nonylphenol polyoxyethylene ether ammonium sulfate, 10 parts of styrene, 7 parts of butyl acrylate, potassium persulfate 7 parts, 315 parts of water.

[0027] A method for preparing the above-mentioned moisture-proof and wear-resistant corrugated paper, comprising the steps of:

[0028] S1: Take 200 parts of waste paper and pulverize it with a shredder, put it in the soaking tank for 6 hours to soak until it becomes weak, then pass through a desander to remove im...

Embodiment 2

[0037] A moisture-proof and wear-resistant corrugated paper, including the following raw materials in various mass fractions:

[0038]250 parts of waste paper, 60 parts of non-woven fabric, 75 parts of super absorbent resin, 90 parts of polyester staple fiber, 40 parts of oyster shell powder, 20 parts of dextrin, 2 parts of borax, 30 parts of paraffin emulsion, 6 parts of silicon dioxide, 2 parts of corundum powder, 5 parts of talc powder, 5 parts of aluminum oxide, 45 parts of oxidized starch, 4 parts of allyloxy nonylphenol polyoxyethylene ether ammonium sulfate, 11 parts of styrene, 9 parts of butyl acrylate, potassium persulfate 10 parts, 450 parts of water.

[0039] A method for preparing the above-mentioned moisture-proof and wear-resistant corrugated paper, comprising the steps of:

[0040] S1: Take 250 parts of waste paper and grind them with a shredder. After crushing, put them in the soaking tank for 7 hours to soak until they become weak, then remove impurities thr...

Embodiment 3

[0049] A moisture-proof and wear-resistant corrugated paper, including the following raw materials in various mass fractions:

[0050] 235 parts of waste paper, 56 parts of non-woven fabric, 80 parts of super absorbent resin, 82 parts of polyester staple fiber, 38 parts of oyster shell powder, 18 parts of dextrin, 1.8 parts of borax, 20 parts of paraffin emulsion, 5 parts of silicon dioxide, 4 parts of corundum powder, 7 parts of talc powder, 4 parts of aluminum oxide, 40 parts of oxidized starch, 3 parts of allyloxynonylphenol polyoxyethylene ether ammonium sulfate, 8 parts of styrene, 12 parts of butyl acrylate, potassium persulfate 5 parts, 418 parts of water.

[0051] A method for preparing the above-mentioned moisture-proof and wear-resistant corrugated paper is characterized in that it comprises the following steps:

[0052] S1: Take 235 parts of waste paper and grind them with a shredder. After crushing, put them in the soaking tank for 6 hours to soak until they becom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com