Automatic real-time tracking method and tracking system for housing construction progress

A technology for building construction and real-time tracking, applied to instruments, data processing applications, resources, etc., can solve problems such as lack of data integrity, neglect of integrity and relevance, and untimely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention is an automatic real-time tracking method for building construction progress, comprising the following steps:

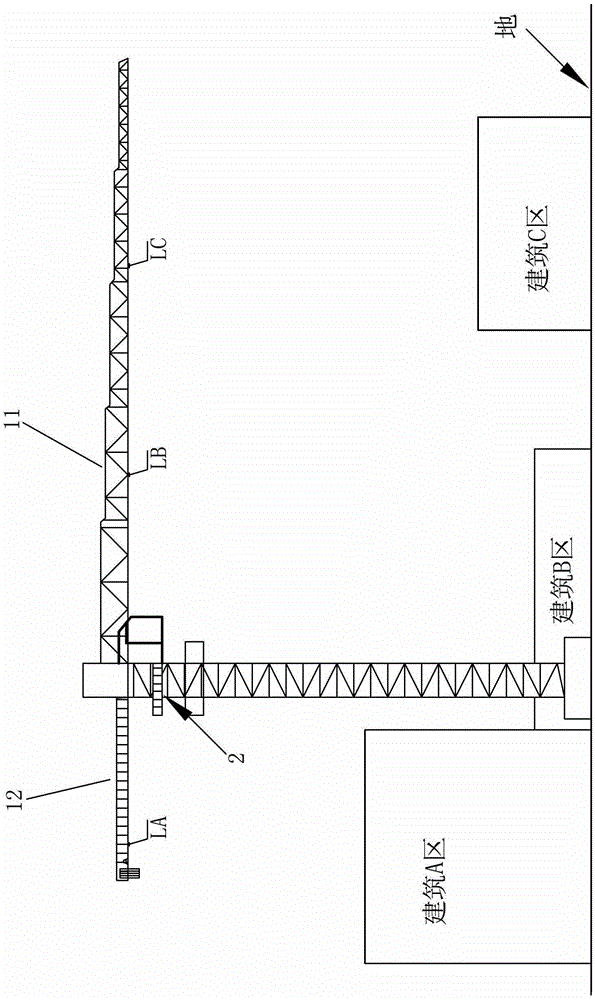

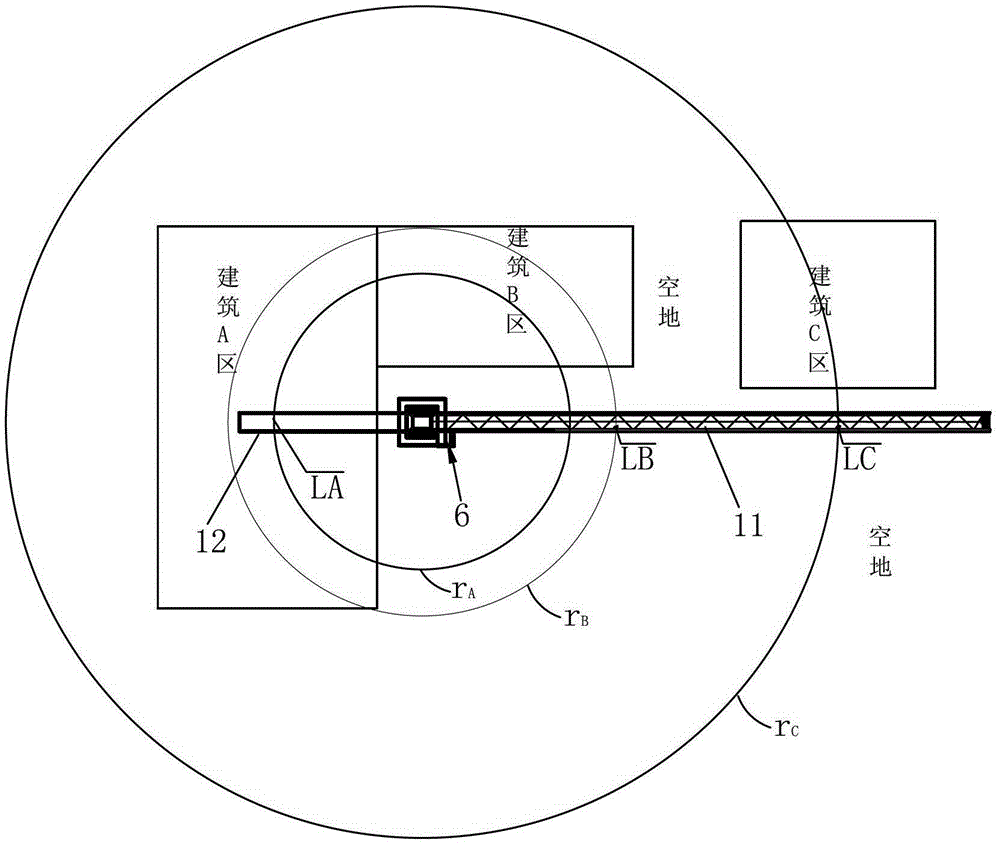

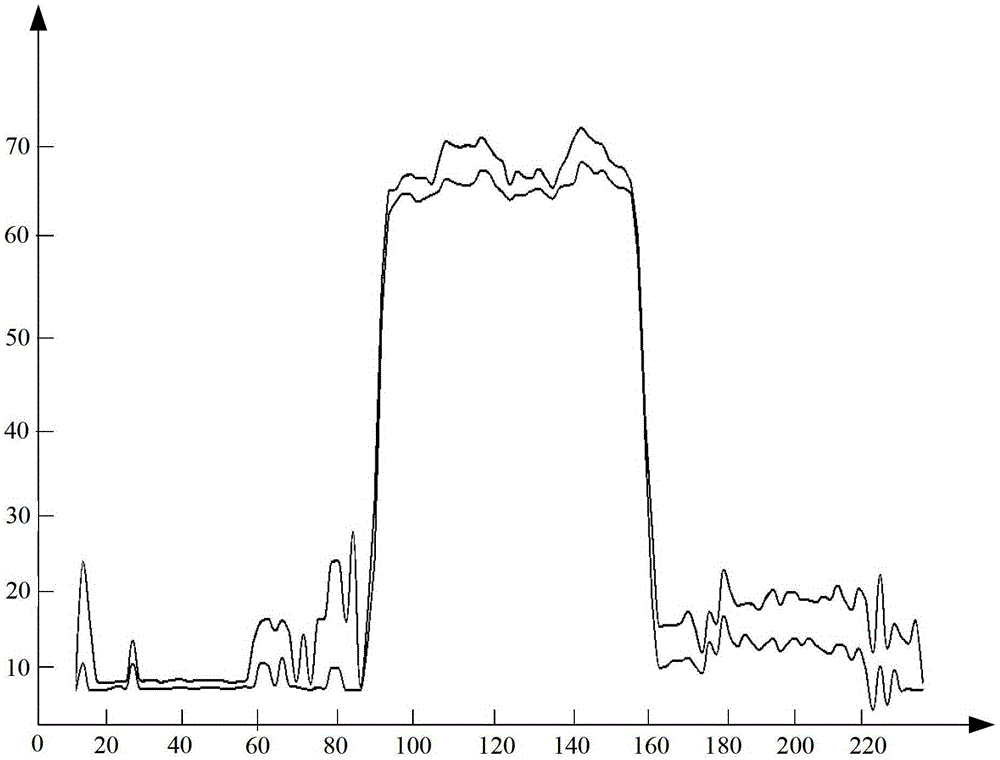

[0077] 1) Refer to figure 1 and figure 2 , set the tracking point on the tower crane ( figure 1 The three points A, B, and C are three tracking points, which are respectively equipped with point A radar LA, point B radar LB, and point C radar LC). With the operation of the tower crane (three-point radar) uninterrupted 360-degree scanning target buildings such as figure 1 and figure 2 For building area A, building B, and building C of different heights, measure the distance between the tower crane tracking point and the target building every 10ms (the measurement time can be taken between 9-11ms), so as to measure the distance between the tower crane tracking point and the target building at different angles The tower crane tracks the distance between the point and the target building, obtains the height reading and stores it in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com