Piezo-electrical actuator module and fuel injection valve

A piezoelectric actuator, fuel injection valve technology, applied in fuel injection devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve problems such as affecting the life of electrical contacts, and achieve improved structure and layout. , the effect of reliable electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

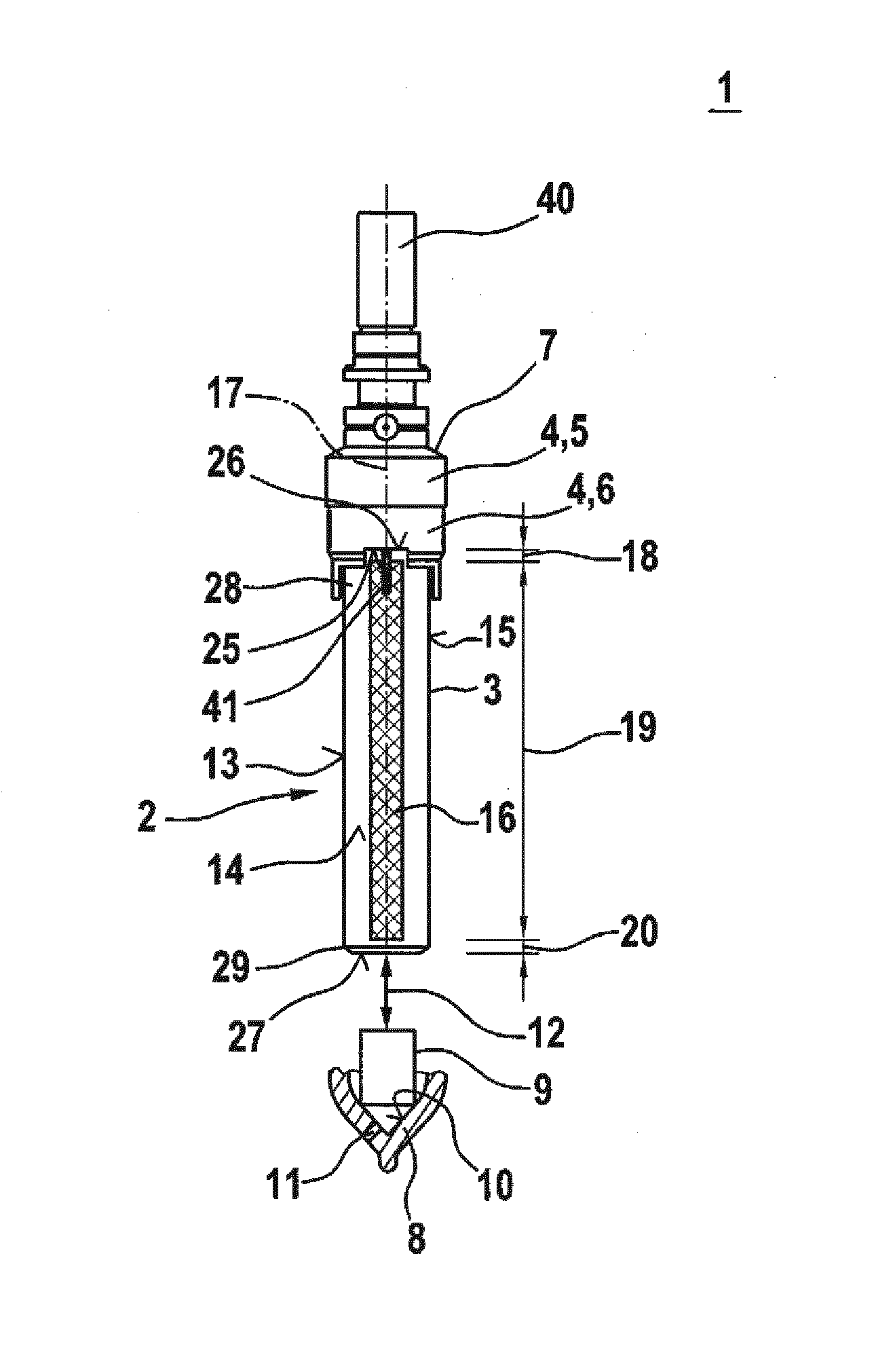

[0013] FIG. 1 shows a schematic diagram of a fuel injector 1 with a piezoelectric actuator module 2 according to an exemplary embodiment of the invention. The fuel injector 1 can be used in particular as an injector for an air-compressing, self-igniting internal combustion engine. The piezoelectric actuator module 2 is particularly suitable for such a fuel injector 1 . However, the fuel injector 1 according to the invention and the piezoelectric actuator module 2 according to the invention are also suitable for other applications.

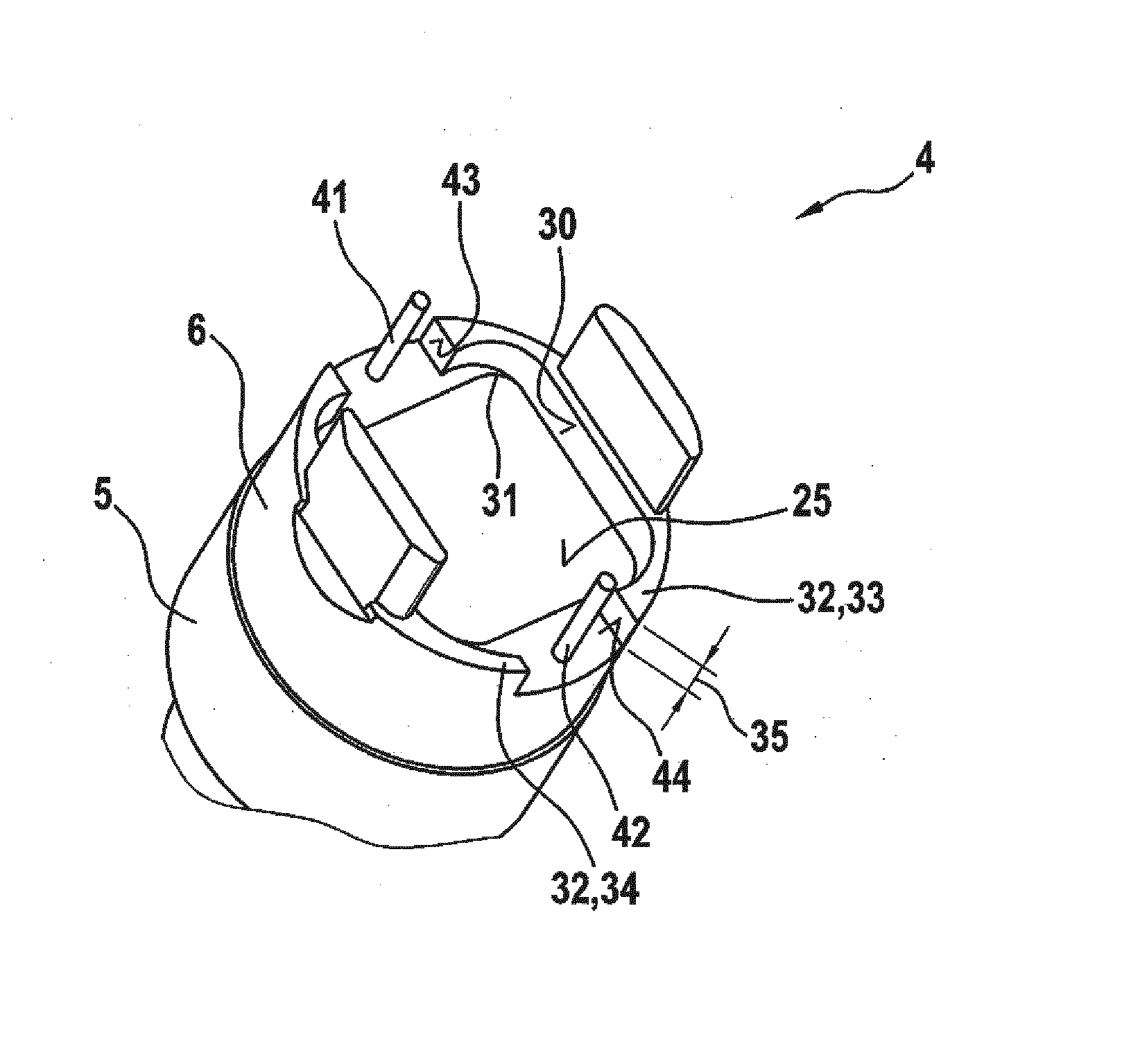

[0014] The piezo actuator module 2 has an actuator body 3 and an adapter piece 4 . In this exemplary embodiment, the adapter part 4 is designed as an actuator foot 4 . The actuator foot 4 has a base body 5 made of metallic material, in particular stainless steel. The actuator foot 4 also has an injection-molded coating 6 made of plastic, which forms a collar 6 for the actuator body 3 . The injection-molded coating 6 is here sprayed onto the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com