Burner

A technology of burners and shapes, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of increasing the risk of ash accumulation, complex auxiliary burners, and difficulty in controlling flame stability, etc., to achieve good flame stability Sexual, less complex to manufacture, high heating capacity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

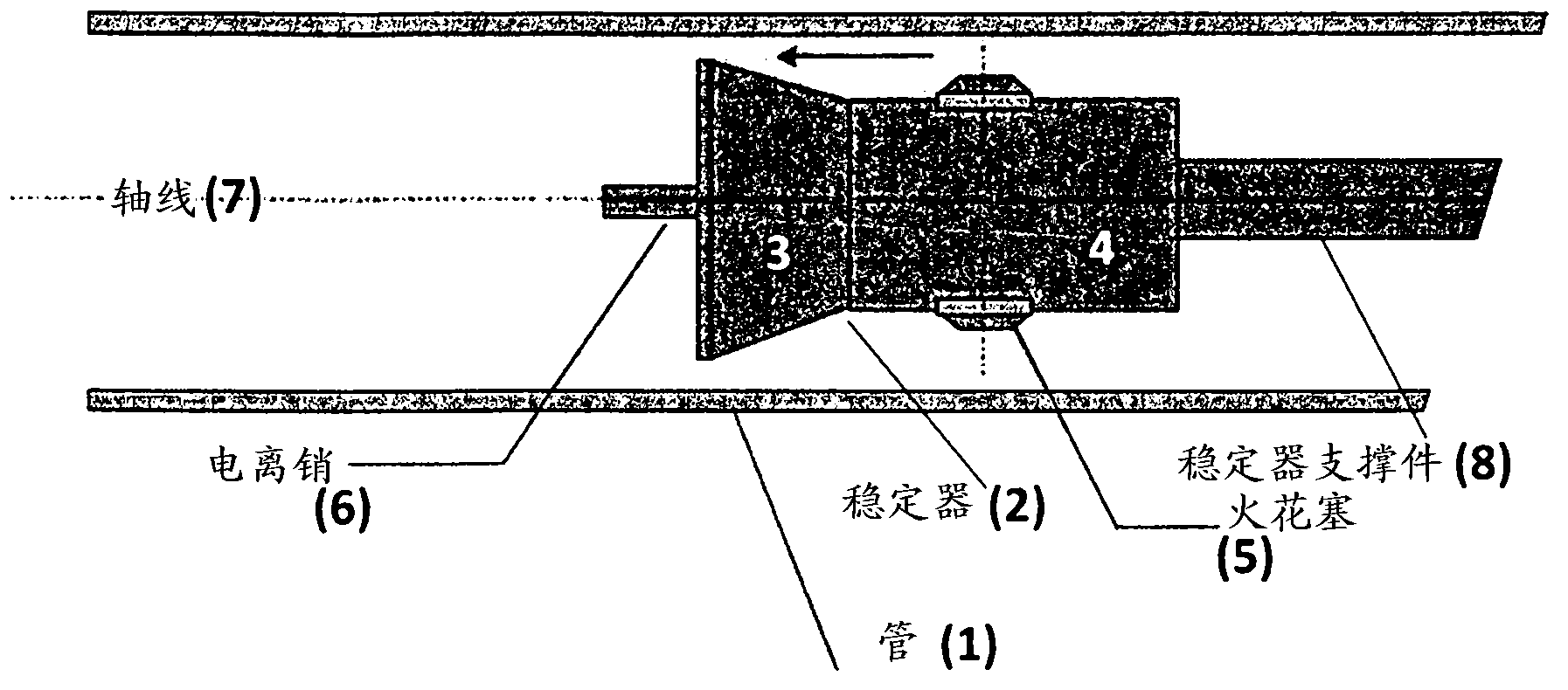

[0035] exist figure 1 , the stabilizer (2) consisting of a conical part (3) and a cylindrical part (4) connected at the upstream end of the conical part (3) is along the longitudinal axis of the burner tube (1) ( 7) Arranged in the center of the burner tube (1). Arrows indicate the direction of flow of the combustible mixture of oxygen-containing gas and fuel gas obtained by mixing fuel gas and oxygen-containing gas in a mixing device arranged in the upstream section of the burner tube. The cylindrical part (4) of the stabilizer comprises a spark plug (5), while an ionizing rod (6) extends from a circular base at the downstream end of the stabilizer (2). The central tube (8) is used to support the stabilizer (2) and to guide the electrical connections to the ionization rod (6).

[0036] example

[0037] Operating at an air / natural gas ratio of 17.2 with an air flow of 688 kg / hr (kilograms per hour) and a natural gas flow of 40 kg / hr is based on figure 1 The burner of the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com