Rotor disc with axial retention of the blades, assembly of a disc and a ring, and turbomachine

A technology for turbines and rotor disks, applied in the direction of blade support elements, mechanical equipment, engine functions, etc., can solve problems such as expensive, time-consuming, and complicated replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

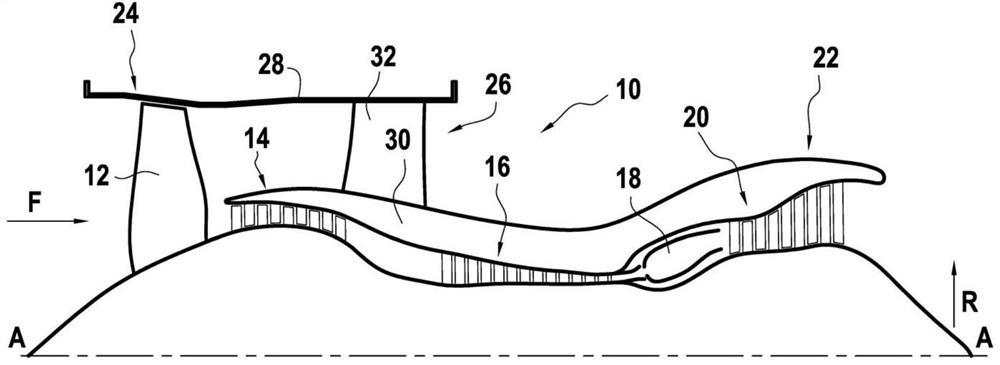

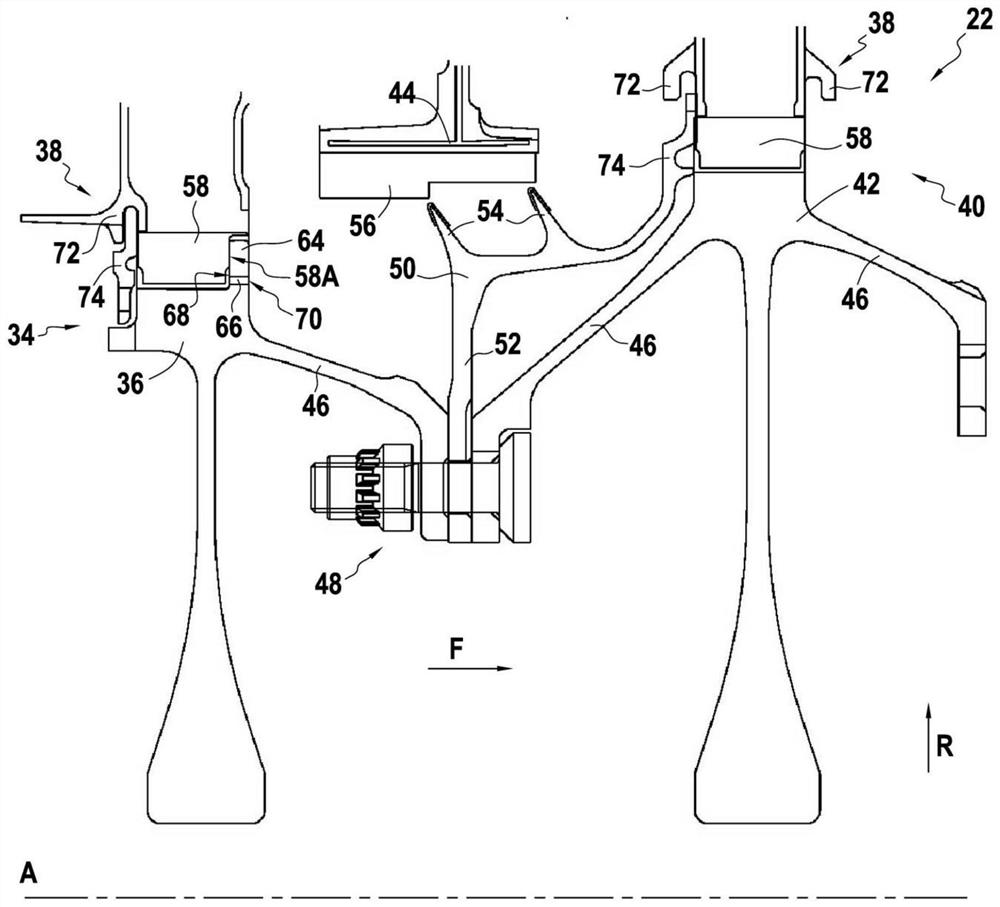

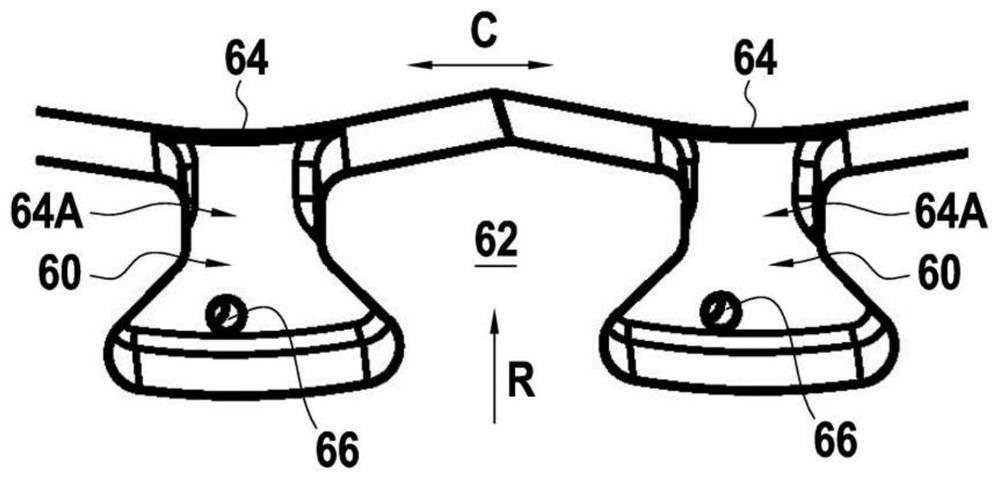

[0056] Figure 1 shows a turbofan engine 10, an example of a turbomachine, in cross-section along a vertical plane passing through its main axis A. Turbofan engine 10 includes fan 12 , low pressure compressor 14 , high pressure compressor 16 , combustor 18 , high pressure turbine 20 and low pressure turbine 22 from upstream to downstream along the cycle of airflow F.

[0057] With respect to the direction of circulation of the air in the turbine, in this case according to the circulation of the air flow F in the turbojet 10 , the terms "upstream" and "downstream" are defined.

[0058]The turbojet engine 10 comprises a fan casing 24 extending rearwardly, that is to say downstream, through an intermediate casing 26 comprising an outer shroud 28 and opposite in radial direction R A parallel inner shroud 30 is arranged inside the outer shroud 28 . The radial direction R is perpendicular to the main axis A.

[0059] The terms "outer" and "inner" are defined with respect to the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com