Thin oil lubrication heating system of cross-cutting production line

A thin oil lubrication and heating system technology, applied in the direction of lubricating parts, engine lubrication, engine components, etc., can solve problems such as affecting heating effect, aggravating oil, oil temperature unevenness, etc., to reduce equipment investment costs, improve Heating capacity and space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

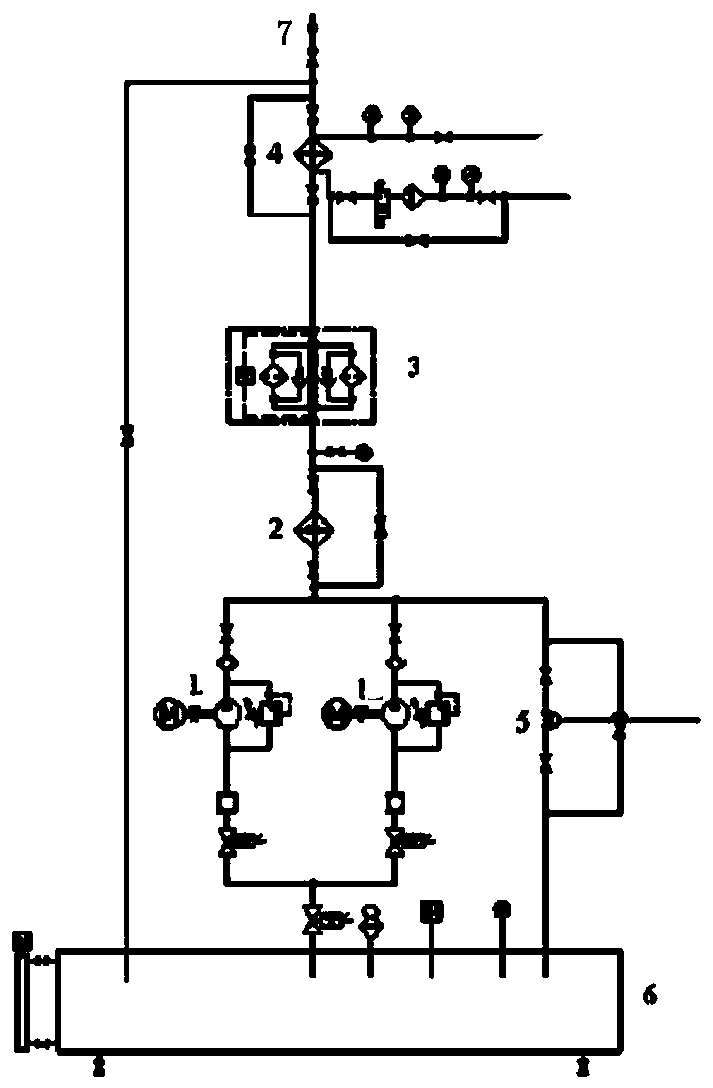

[0014] A thin oil lubrication heating system for a cross-cutting production line according to the present invention includes an oil pipeline 7, the output end of the oil pipeline 7 is connected to the oil tank 6 through a double cylinder filter 3 and a pipeline heater 2, and the oil pipeline 7 A plate cooler 4 is provided between the output end of the liquid pipeline 7 and the duplex filter 3 ; a pneumatic pressure regulating valve 5 is provided between the pipeline heater 2 and the oil tank 6 .

[0015] Both valves are respectively connected with the pneumatic pressure regulating valve 5 .

[0016] The filtration accuracy of the duplex filter 3 in this embodiment is 80 μ.

[0017] The volume of the mailbox described in this embodiment is 5 cubic meters.

[0018] The oil flows out from the oil pipeline 7, passes through the pipeline heater 2, and realizes the heating effect by exchanging heat with the pipeline heater 2, and then enters the oil tank 6 after being filtered by t...

Embodiment 2

[0020] This embodiment is basically the same as Embodiment 1, the difference is that this embodiment is provided with two oil passages between the pipeline heater 2 and the oil tank 6, and each oil passage is provided with a valve, each of which Each oil channel is provided with a screw pump 1, and each screw pump 1 is connected with a motor, and the flow rate of the screw pump 1 is 206 liters per minute. In this embodiment, two screw pumps 1 divide the flow of the liquid in the pipeline heater 2 and then flow into the oil tank 6, which avoids a large loss of oil temperature and relieves the pipeline pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com