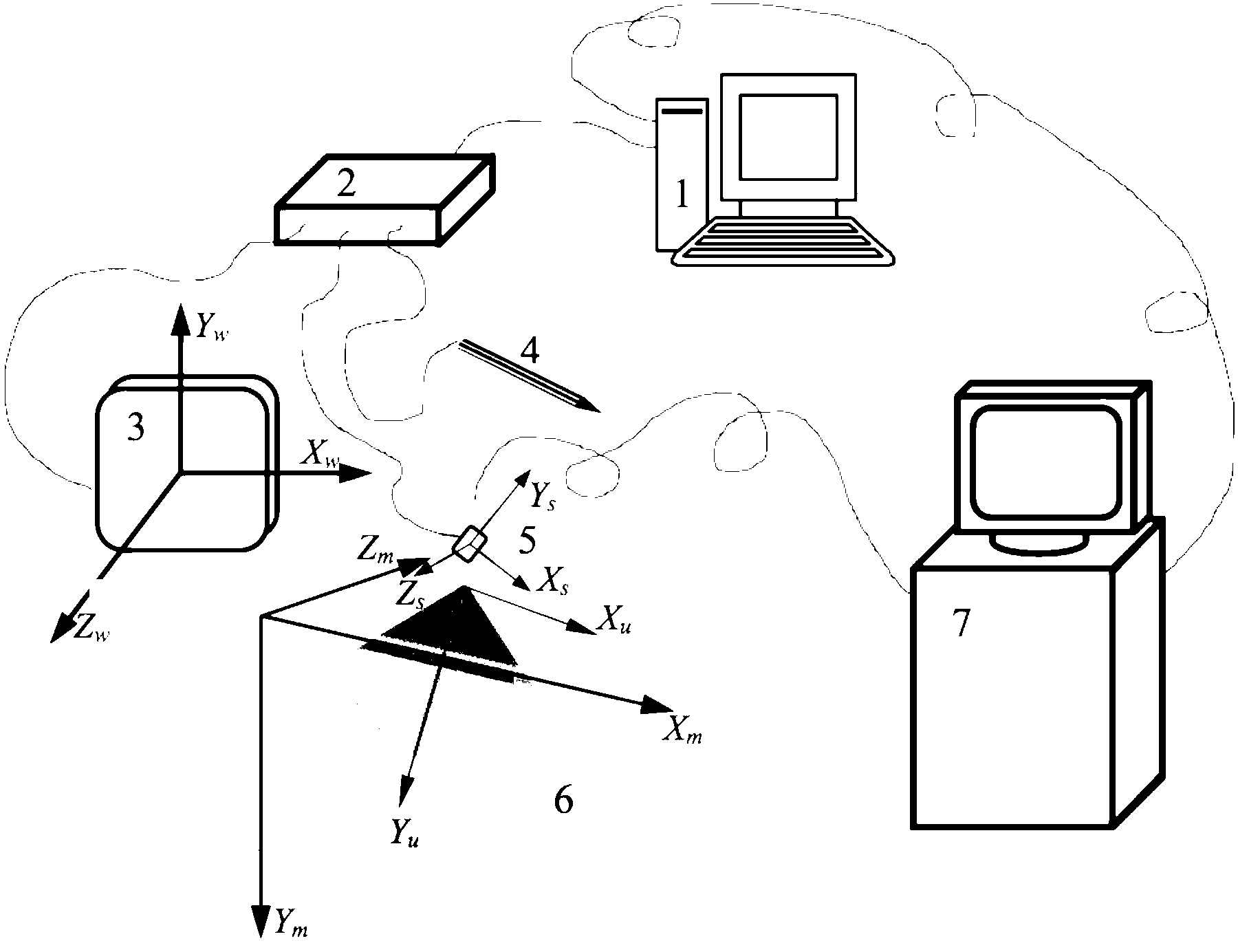

Method for optimizing ultrasonic probe imaging plane space position calibration

A technology of spatial position and ultrasonic probe, applied in ultrasonic/sonic/infrasonic diagnosis, ultrasonic diagnosis, infrasonic diagnosis, etc., to achieve good practical value, scientific and reasonable processing of measurement and calibration, and improve the effect of calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

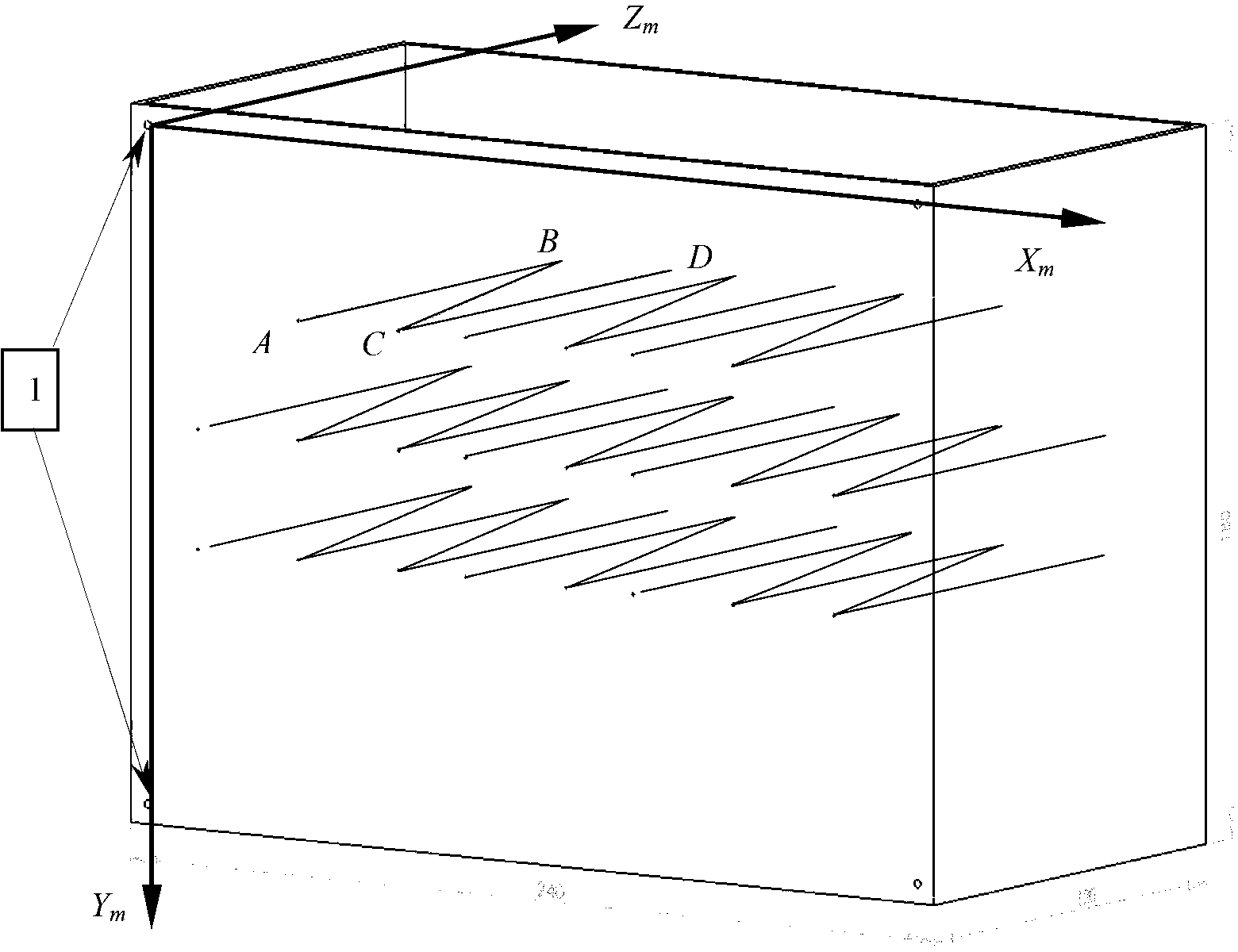

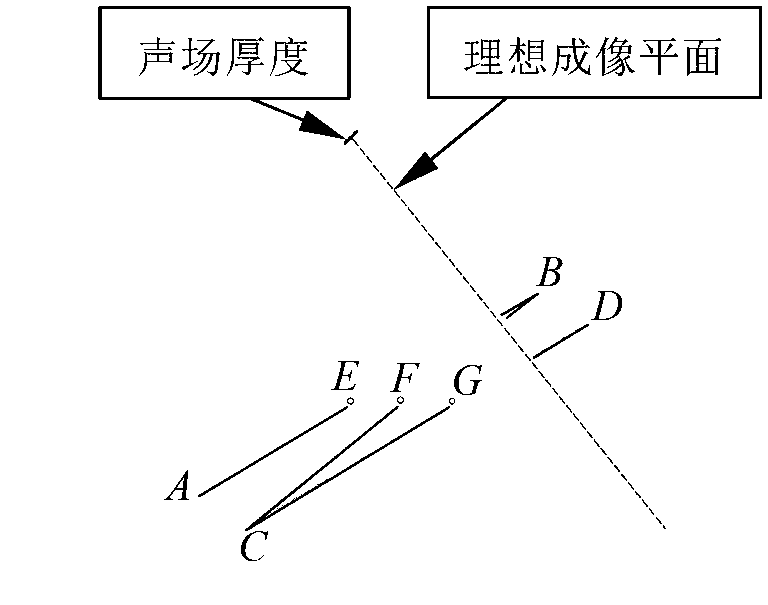

Method used

Image

Examples

Embodiment Construction

[0043] In order to realize the solution method proposed by the present invention and verify its effectiveness, we have actually built a test system and conducted a performance test comparison experiment, comparing the traditional N-line The calibration method and the solution accuracy of the method of the present invention and the repeatability error of calibration, and the situation that the error decreases with the number of ultrasonic images participating in the calibration, experiments have confirmed that the method of the present invention can be faster when there are multiple ultrasonic images. The calibration error is reduced, and the calibration accuracy is better when there is a larger "thickness error", so that the calibration process of the probe can be easier and more reliable. Figure 8 Provide the program flowchart of the present invention in, the example of the test comparison of concrete realization is as described in the following steps:

[0044] Step 1: Build...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com