Cooling type high-efficiency extracted product dry magnetic separator

A dry separation machine and cooling technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of inability to dissipate heat, inability to increase the rotation speed, and increase in temperature in the barrel, so as to increase the comprehensive operation rate and the rotation speed of the spindle The effect of improving and reducing the cost of ton consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

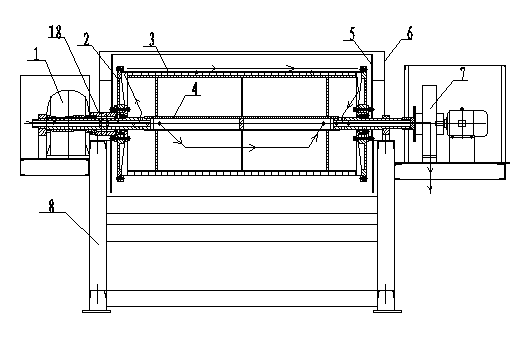

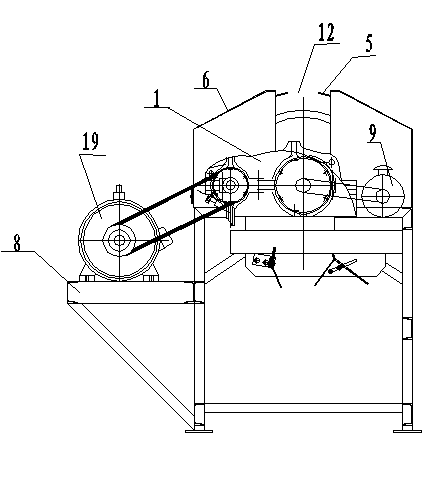

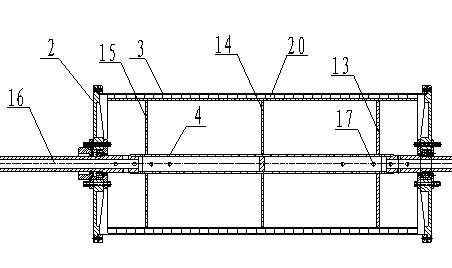

[0032] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0033] attached figure 1 It can be seen that a cooling-type high-efficiency product extraction dry selection machine includes a reducer 1 connected to a motor 19 and a main shaft magnetic barrel 4. The main shaft magnetic barrel 4 is composed of a hollow main shaft 16, an aluminum disc 2, and an outer cylinder 3. The reducer 1 The aluminum disc 2 is connected to the outer cylinder 3 through the coupling 18, the magnetic block is stuck on the magnetic barrel and wrapped by the outer cylinder, and the outer cylinder 3 is provided with a reversible multi-piece return plate 5 , the outer side of the reversible multi-piece return plate 5 is provided with a protective cover 6; the reversible multi-piece return plate 5 is provided with a stainless steel plate 10, and the stainless steel plate 10 is connected to the inner wall of the reversible multi-piece return plate 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com