Detection roller, contact shaper and detection system

A detection roller and contact technology, which is applied in the field of plate shape detection of strip and foil cold rolling mills, can solve the problems of high machining accuracy, complicated signal output lead mechanism, and reduced service life of the instrument, so as to achieve machining accuracy Requirements for lower assembly accuracy, reduced manufacturing and maintenance costs, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, invention is described in further detail.

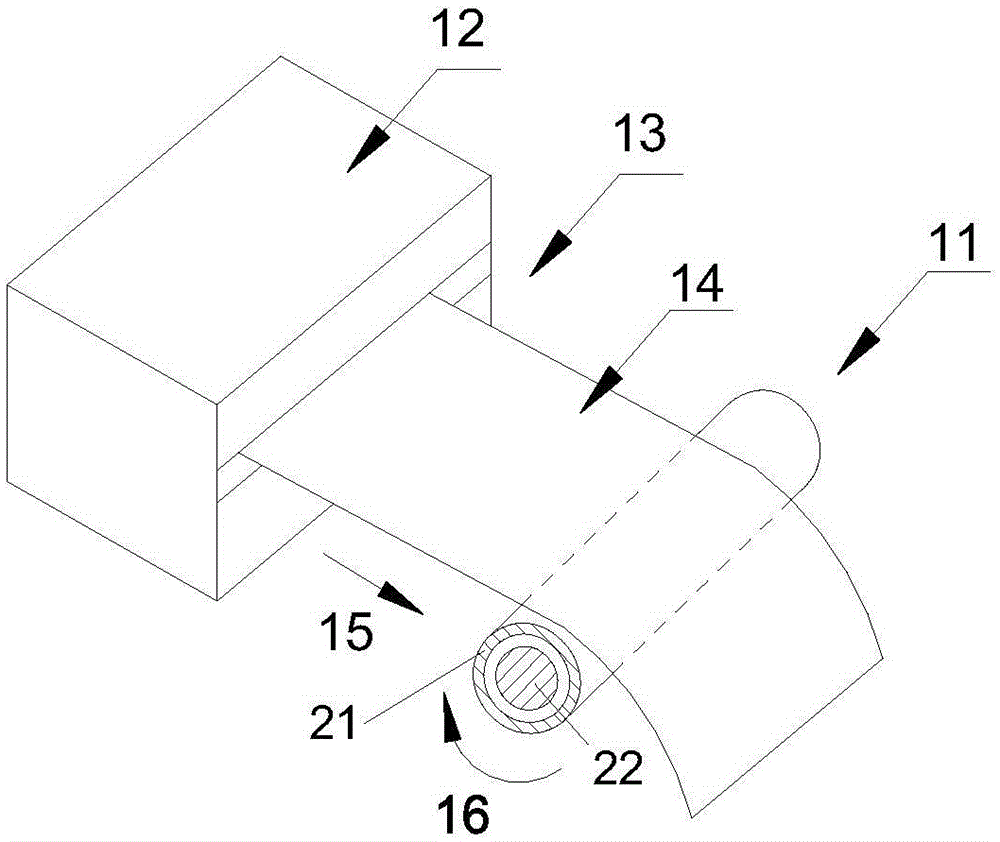

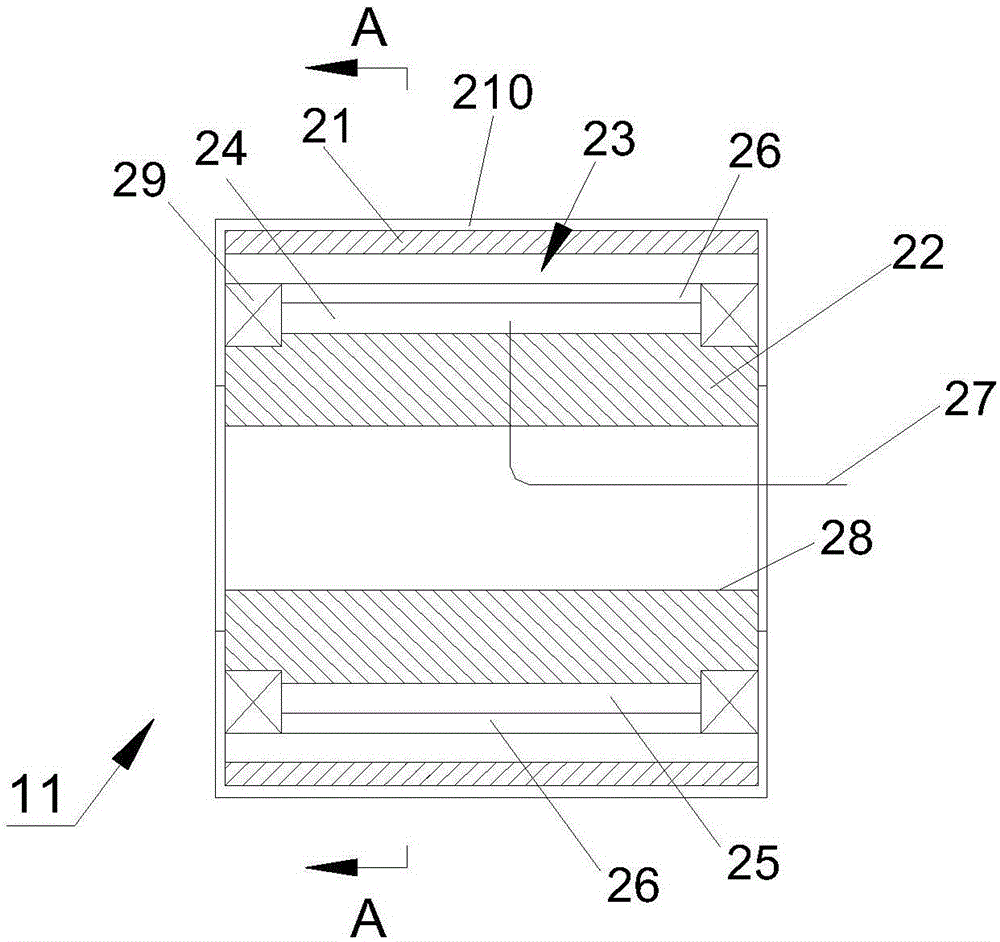

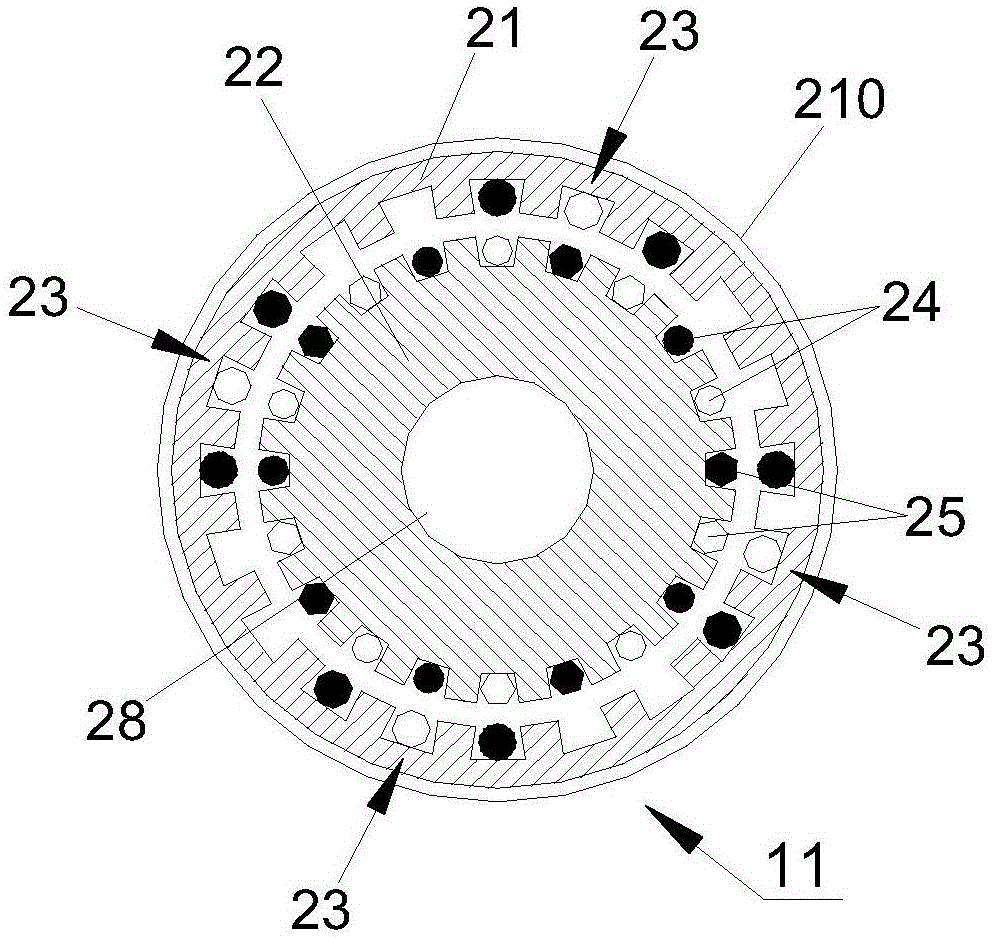

[0026] Such as figure 1 , 2 , 3 show the first embodiment of the detection roller of the present invention. Such as figure 2 , 3 As shown, in the detection roller 11 among the present invention, comprise: annular pressure magnet core 21, stator iron core 22, 4 groups of closed induction coils 23 (the solid circle and the hollow circle at 23 places indicated in the figure respectively represent the difference in the coil The current direction) is fixedly entangled in the groove of the annular compression magnet core 21, and multiple sets of excitation coils 24 (the solid circles and hollow circles at 24 in the figure represent different current directions in the coils respectively) and multiple sets of output The coils 25 (the solid hexagons and hollow hexagons at 25 in the figure respectively indicate different current directions in the coils) are distributed in a staggered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com