Rail damage testing device and method based on three-way electromagnetism differential sensor

A technology of differential sensors and detection devices, applied in transportation and packaging, railway car body parts, railway auxiliary equipment, etc., which can solve problems such as low efficiency, impact on normal railway operation, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

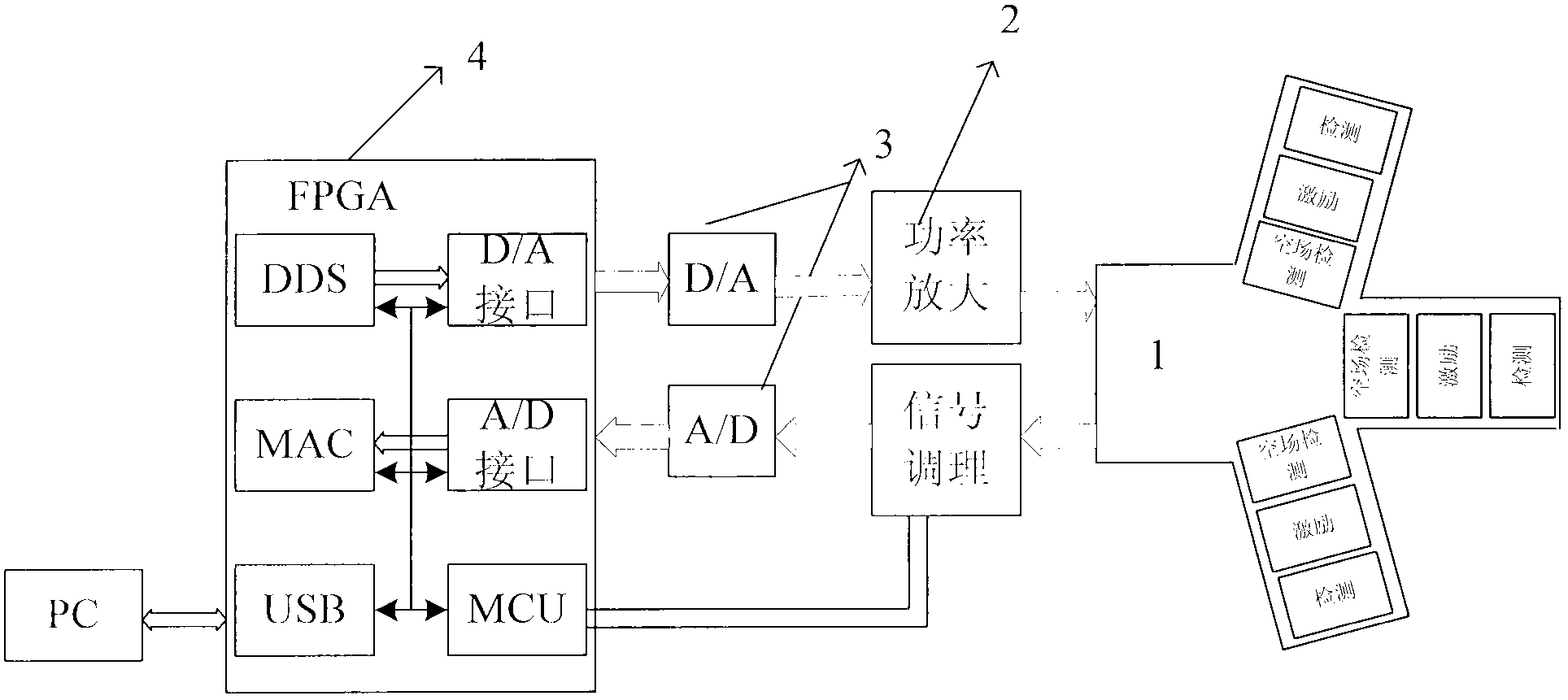

[0014] The following combination Figure 1 ~ Figure 3 , a preferred embodiment of the present invention is described in detail. The detection device provided by the invention is used for real-time monitoring of rail damage and timely feedback of information to rail maintenance station personnel. The entire detection device specifically includes: a three-way electromagnetic differential sensor 1; a power amplifier circuit and a signal conditioning circuit 2 connected to the three-way electromagnetic differential sensor 1 through lines; and an A / D and a D / A connected to the signal conditioning circuit and FPGA a conversion circuit 3; and an FPGA chip 4 as a controller.

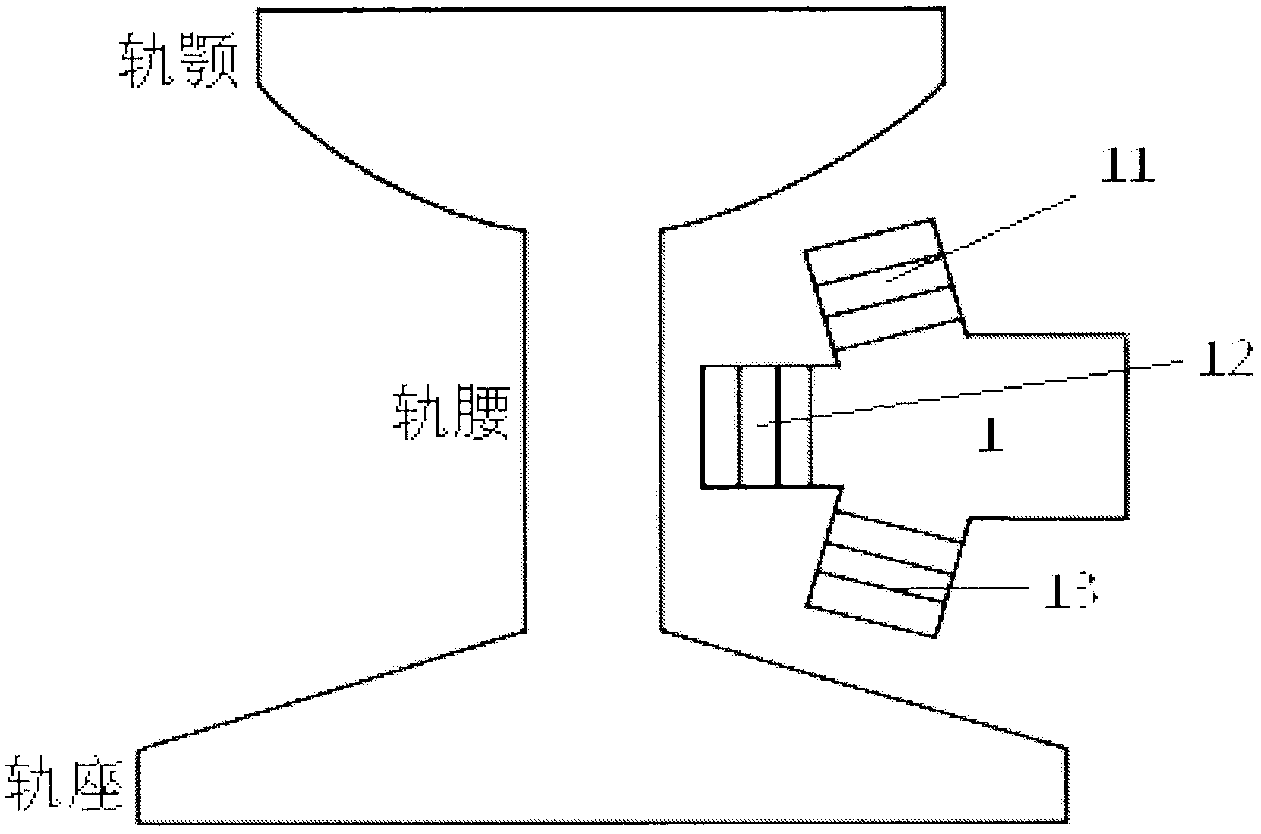

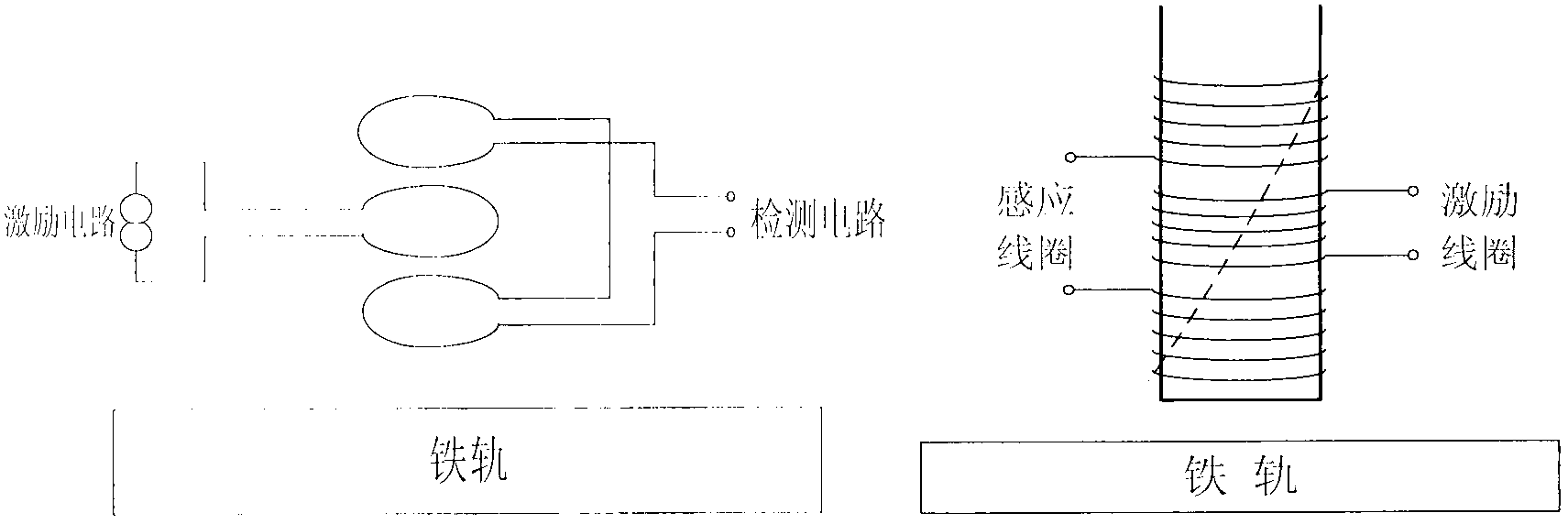

[0015] figure 1 It is a schematic diagram of the main structure and installation parts of the three-way electromagnetic differential sensor 1 of the present invention. The three-way electromagnetic differential sensor 1 of the present invention adopts a three-way design and includes a bracket 14. The front pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com