Arc-shaped ship bow molded line design for dredging green water of high speed vessel

A wave and arc technology on the deck, applied in the hull design, hull, hull bow and other directions, can solve the problems affecting the performance of the ship, achieve the effect of improving safety and comfort, reducing fuel consumption and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

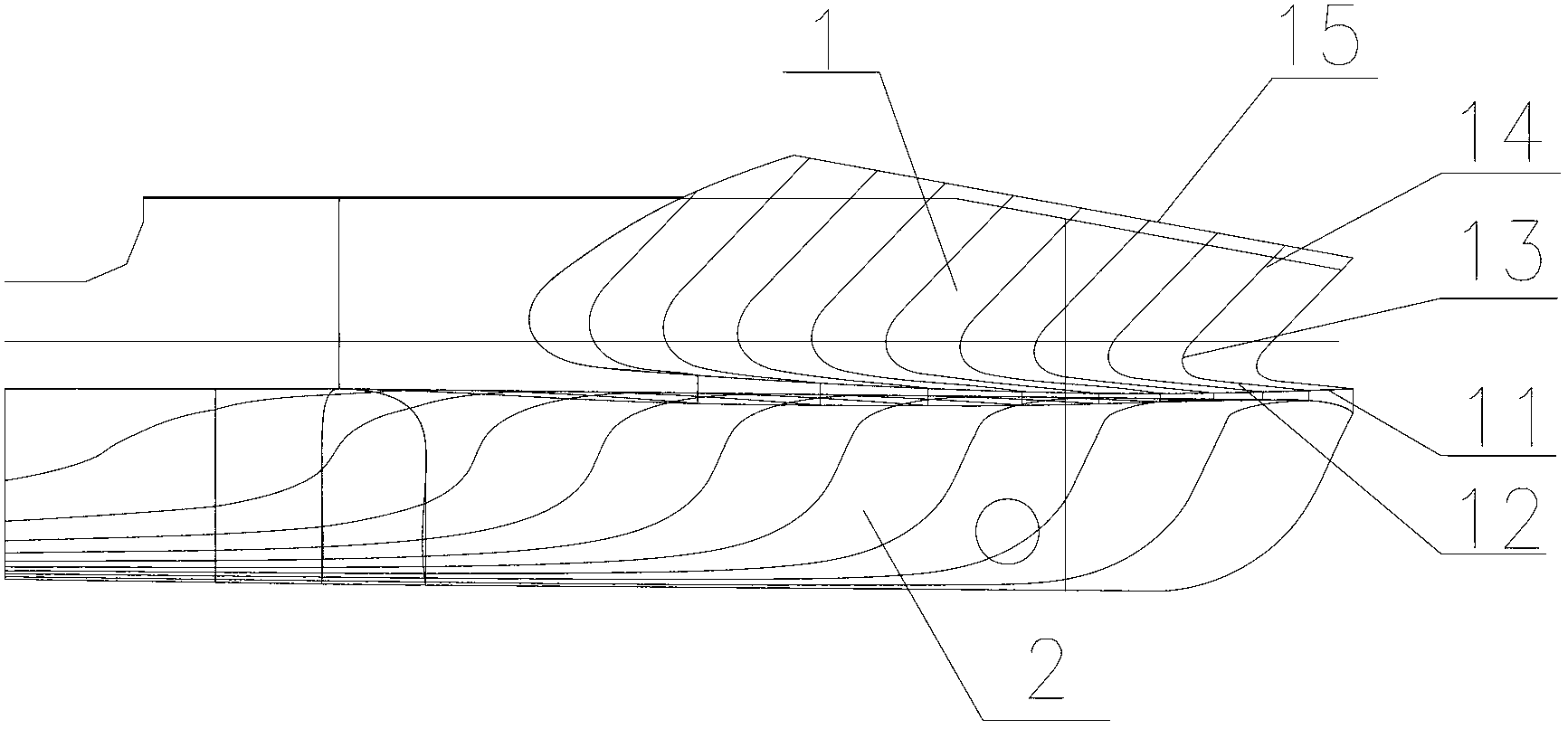

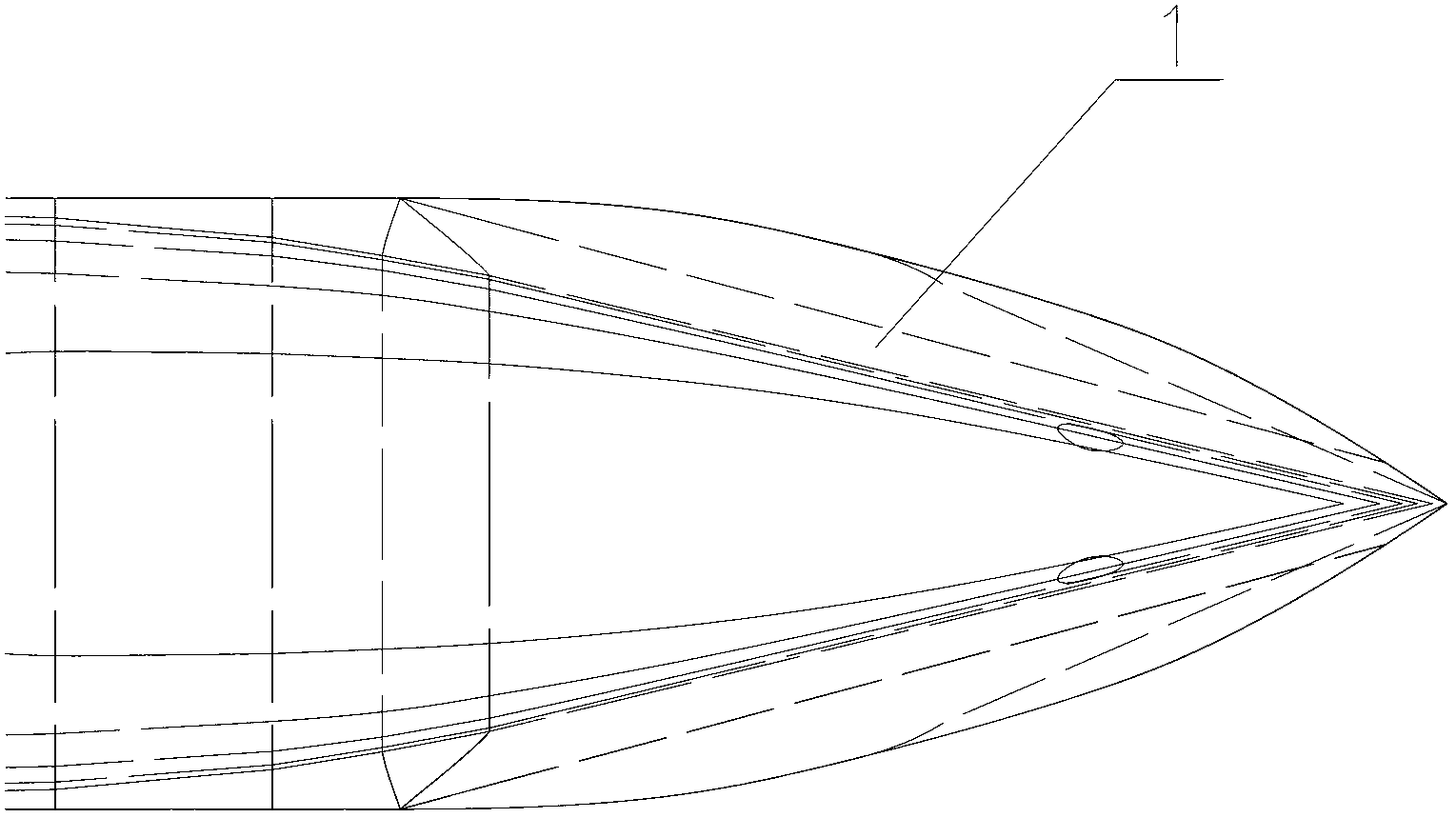

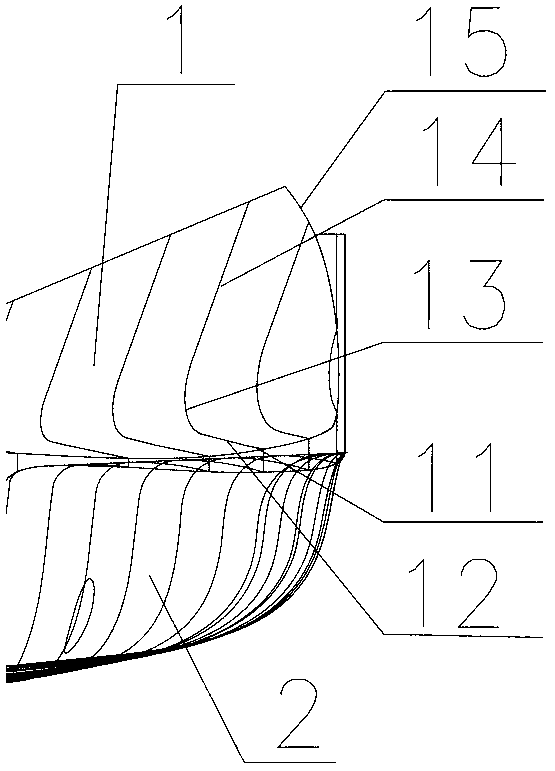

[0015] Such as figure 1 , figure 2 with image 3 As shown, an arc-shaped bow shape design for dredging waves on the deck of a high-speed ship, the wave evacuation part 1 accounts for one-third of the total length of the hull, and the outer hull of the bow includes: the wave evacuation part 1 and the main body Part 2; the wave evacuation parts 1 on both sides of the hull are symmetrical to each other, and the evacuation part 1 includes: a straight part 11, a streamline part 12, a groove part 13, an arc part 14 and an inclined part 15; the bow An arc-shaped main body 2 is arranged under the outer hull, and the top of the main body 2 is arc-shaped connected with the straight part 11 at the bottom of the wave-discharging part 1. The straight part 11 is a straight plate structure, which can block the straight The waves below the part 11 do not impact the upper wave evacuation part 1, so that the waves on the evacuation part 1 can be easily discharged out of the hull, and the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com