Heavy-duty laminated elevated floor and its construction method

A construction method and heavy-duty technology, which is applied to truss structures, basic structure engineering, building components, etc., can solve the problems of complex construction, inability to completely solve the problem of settlement, and high cost, and achieve convenient construction, reduced steel consumption, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

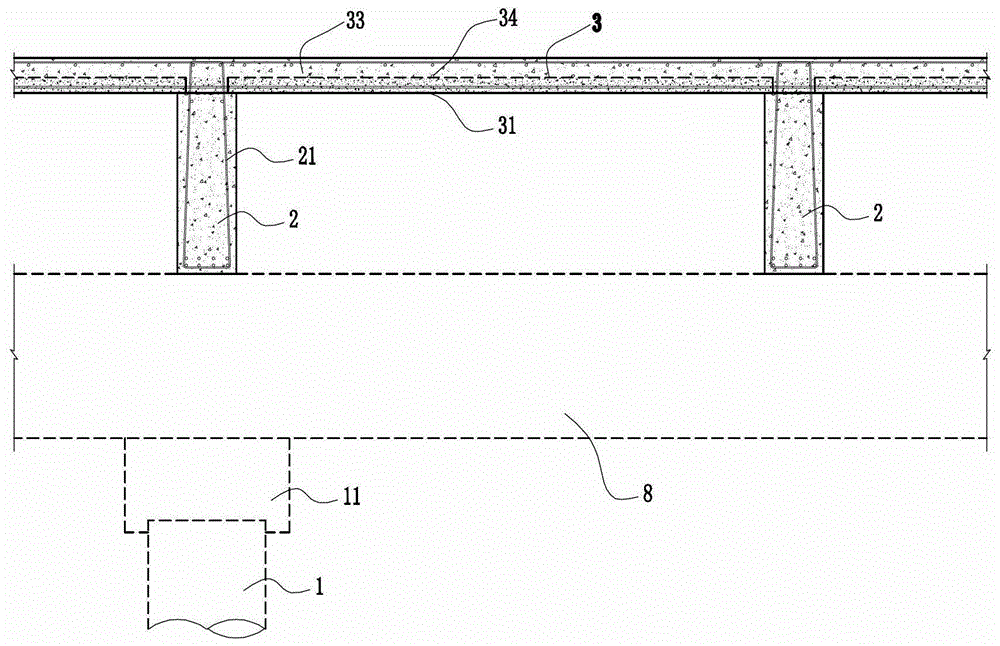

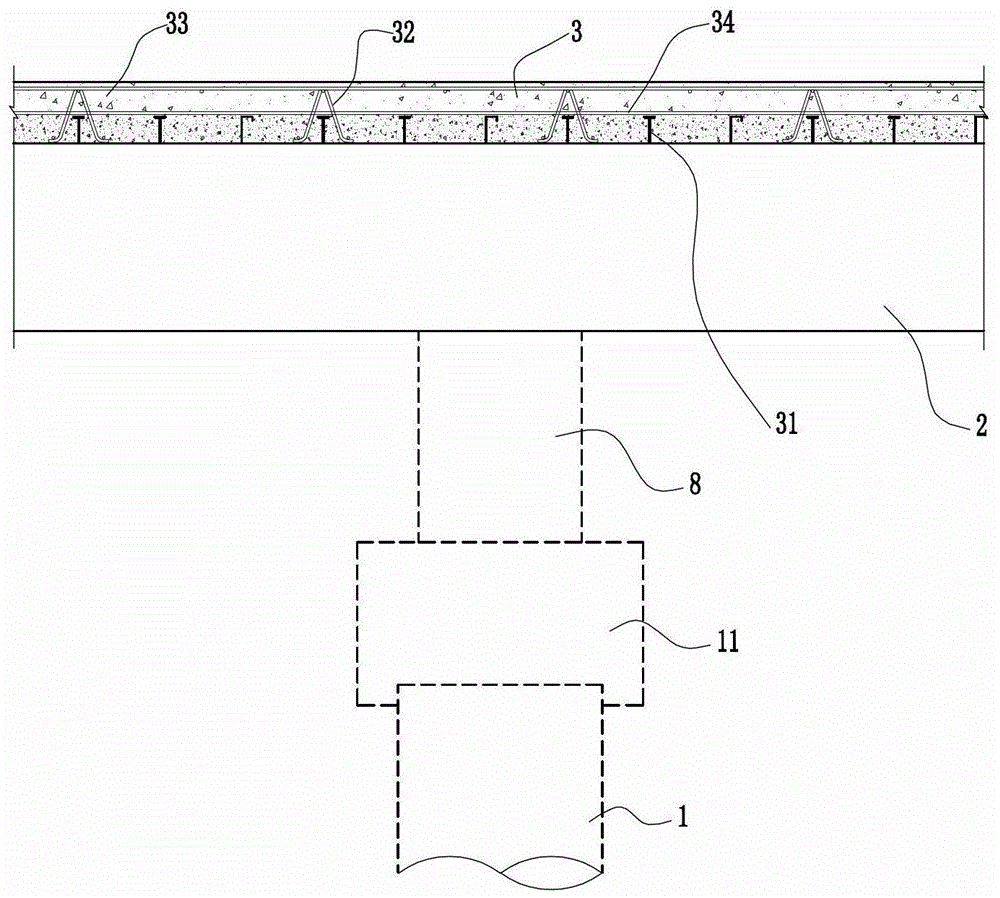

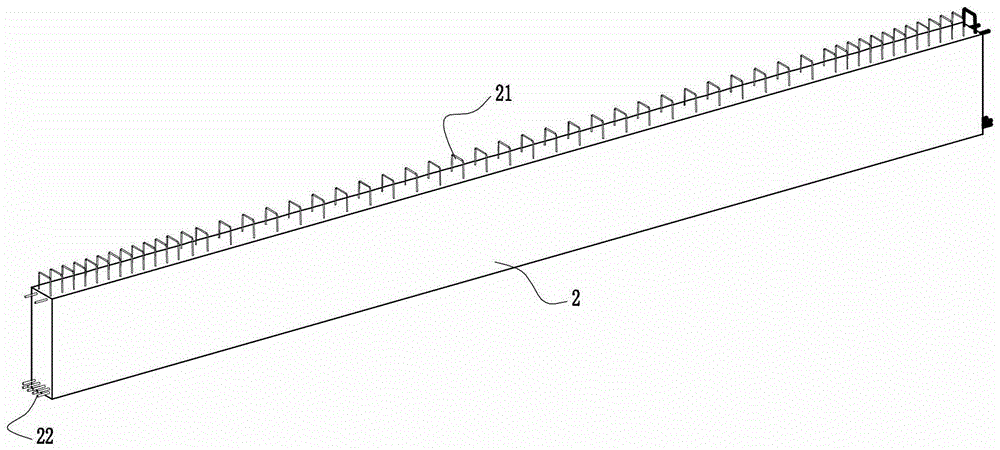

[0026] see Figure 1 to Figure 5 , a heavy-duty superimposed elevated floor 1 provided in the present invention includes piles, prestressed prefabricated beams 2 and composite floor slabs 3, and pretensioned prestressed steel strands 22 are embedded in the prestressed prefabricated beams 2, The prestressed prefabricated beam 2 rests on the pile 1, and the composite floor 3 is composed of closed profiled steel plate 31, steel bar truss 32 and concrete 33. In soft soil areas, the bearing capacity of the foundation is poor. In order to prevent the heavy-duty floor from settling, piles must be driven to bear the load of the floor. The steel strand is used as the main reinforcement, the amount of reinforcement is greatly reduced, and the deflection of the beam is small, and the height of the beam can be reduced. The prestressed prefabricated beam can be placed directly on the pile, or on the pile cap, and can also be placed on the joint if necessary. On the ground beam at the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com