Coal-rock interface recognition handheld system

A coal-rock interface technology, applied in the field of coal-rock interface identification handheld system, can solve the problems of high coal ash content, high gangue content in coal output, poor working environment, etc., to improve the degree of automation, reduce labor load, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

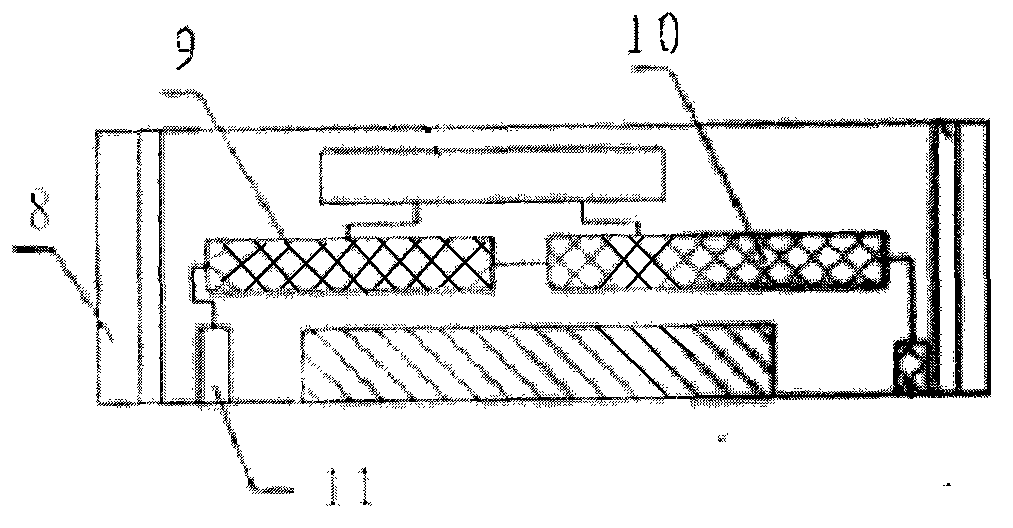

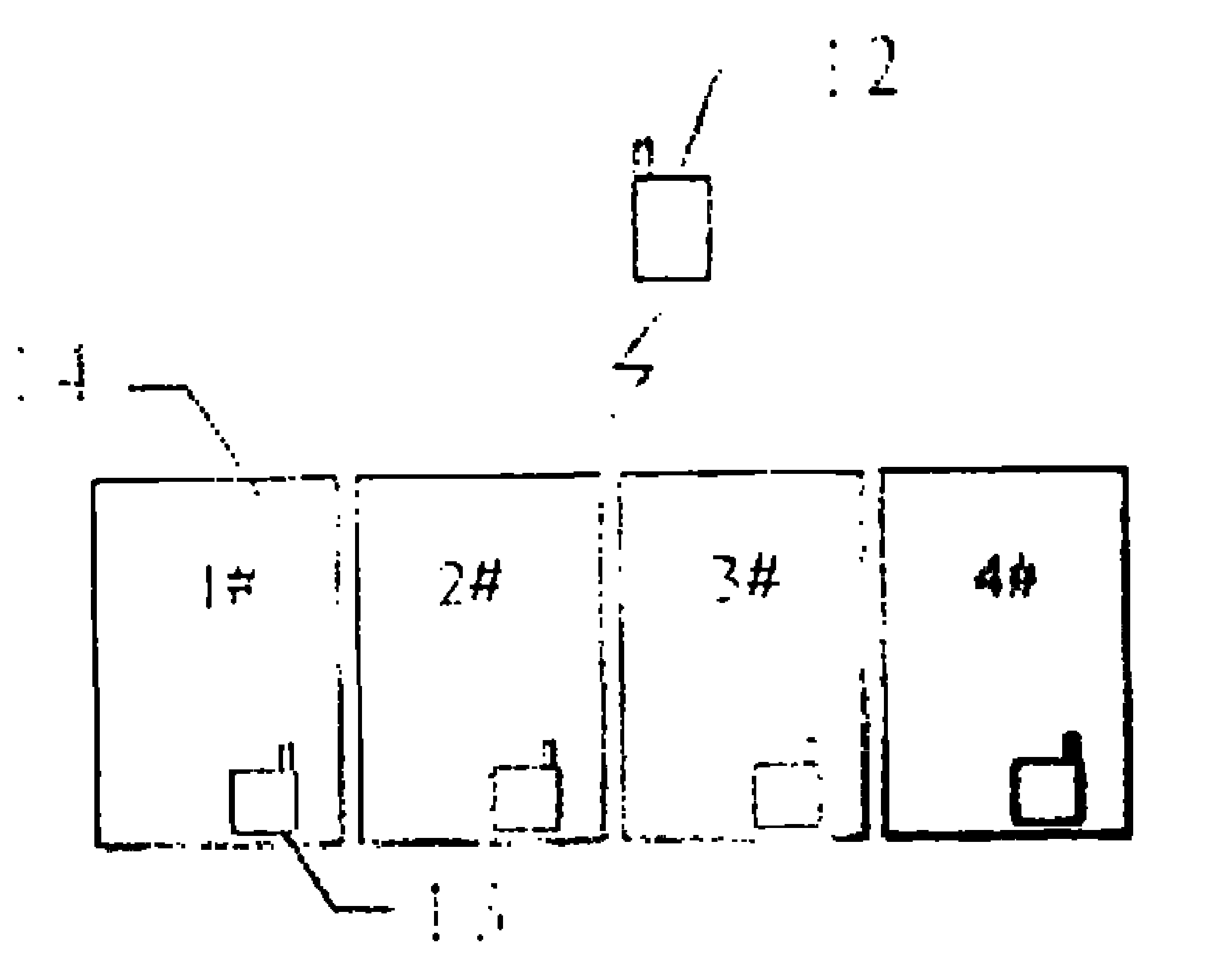

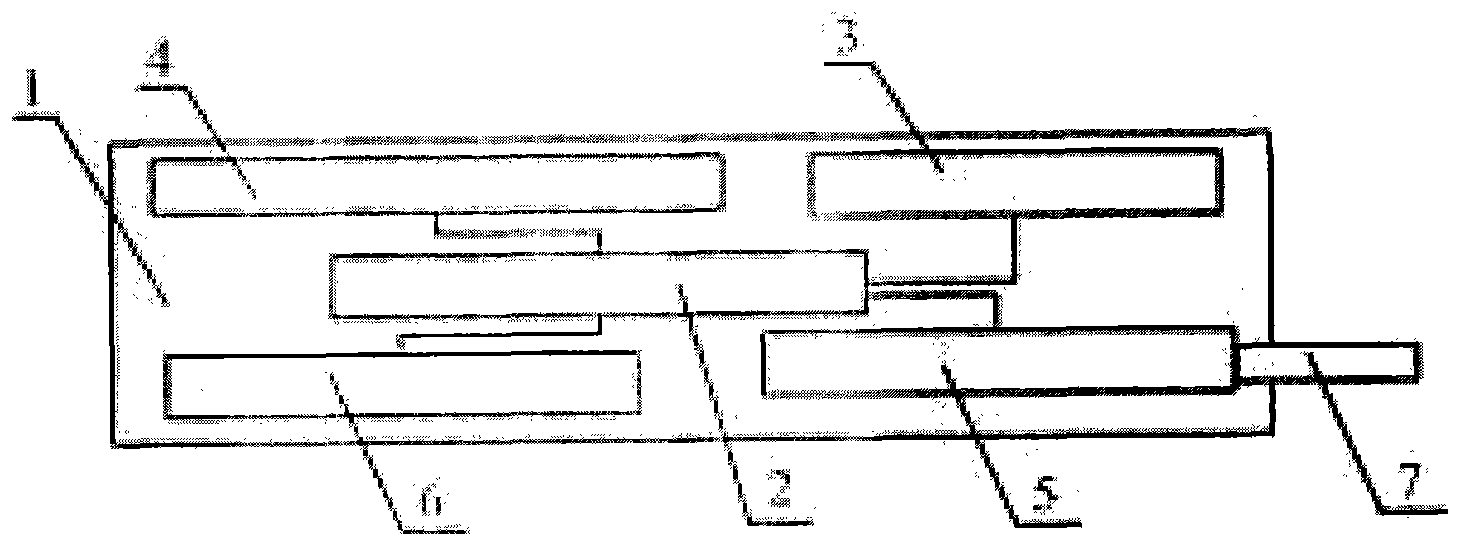

[0019] See attached Figure 1-2 , which describes an embodiment of the hand-held system for coal-rock interface recognition according to the present invention. The coal-rock interface recognition processor is installed on the tail beam of the top coal caving hydraulic support or the rocker arm of the shearer, and is mainly used for collecting coal-rock interface signals during coal caving or coal mining. The first casing is fixedly connected to the tail beam or the rocker arm. In occasions where the vibration is small, a magnet can be set outside the casing in an enveloping manner. On the rocker arm, in order to achieve the purpose of fixing, in the case of large vibration, a mounting hole can be set on the first shell, and the shell can be fixed and tightened on the tail beam of the caving hydraulic support or the shearer through the mounting hole with screws. On the rocker arm, of course, the above two fixing methods can also be used at the same time to enhance the fixing e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com