Demisting and ice-making apparatus and method using liquefied natural gas cold energy

A liquefied natural gas and cold energy technology, applied in ice making, ice making, application, etc., can solve the problems of difficulty in obtaining good economic benefits, unreasonable utilization of equipment, high maintenance and operation costs, and achieve a safe and reliable cold energy recovery process. , the effect of eliminating cold pollution and reducing cold pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

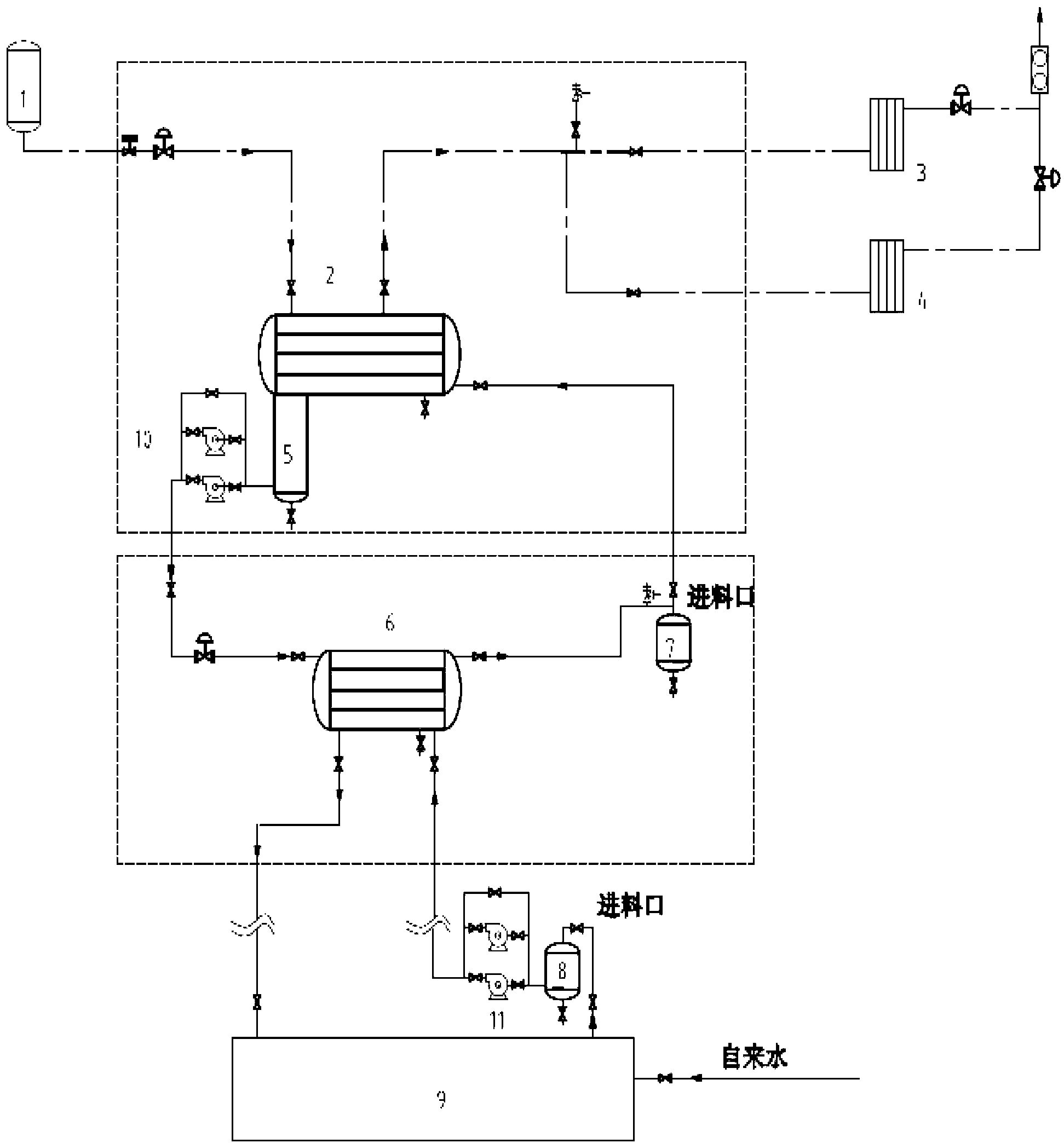

Method used

Image

Examples

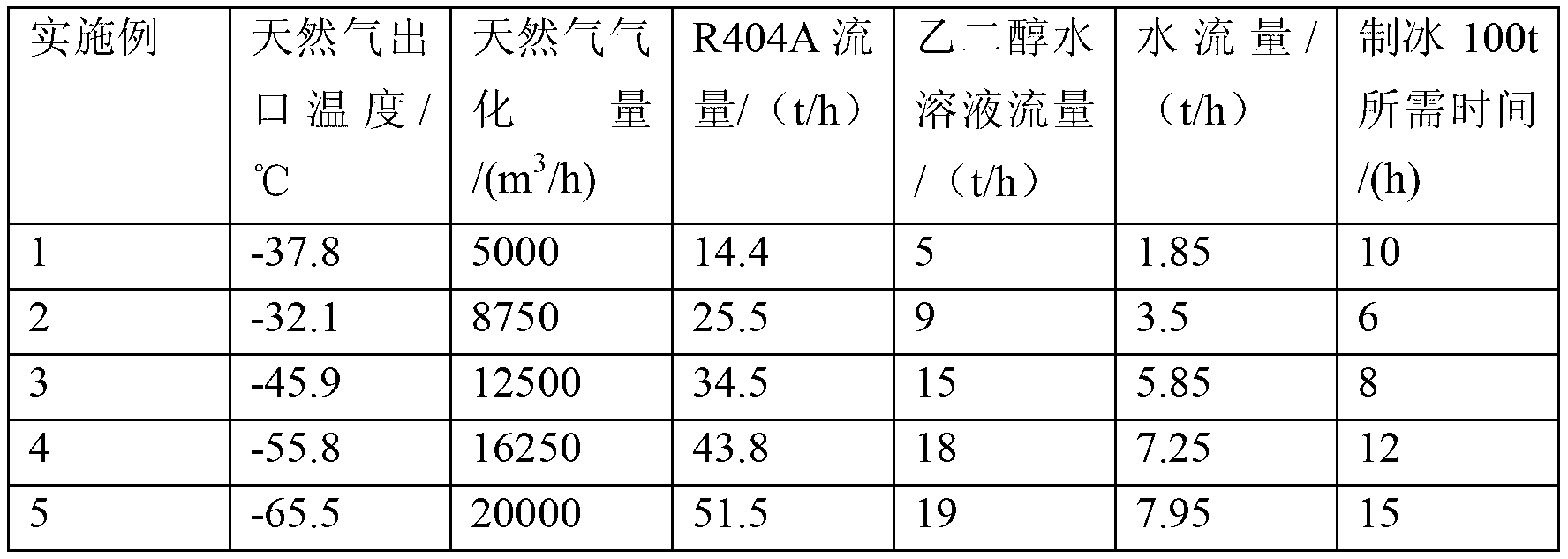

Embodiment 1

[0028] An ice machine with an ice-making capacity of 100 tons / day is used as the terminal equipment for LNG cold energy release, and the gasification capacity of LNG is 9000m 3 / h, its cold release can just meet the demand of 100 tons of ice production per day. However, according to the statistics of the actual operation of the gasification station, the gasification volume of LNG is 9000-20000Nm 3 In the / h stage, the cooling capacity released by gasification is greater than the cooling capacity required to make 100 tons of ice. Therefore, by removing the cooling water in the ice machine, the excess cooling capacity other than ice production is released in time to ensure that the cooling capacity is reduced at the peak of gasification. The effect of fog.

[0029] -162℃, 5000m 3 The liquefied natural gas per hour is gasified by the gasifier, and then becomes normal temperature natural gas and enters the natural gas pipeline network. The visibility in the gasification station...

Embodiment 2

[0032] -162℃, 8750m 3 The liquefied natural gas per hour is gasified by the gasifier, and then becomes normal temperature natural gas and enters the natural gas pipeline network. The visibility in the gasification station was less than 8m in 60 minutes, and the staff could operate it. The cold fog spread to the surrounding residential areas, reducing the ambient temperature; the cold fog spread to the surrounding roads, and the visibility gradually decreased, affecting traffic.

[0033] -162℃, 0.4MPa, 8750m from LNG storage tank 1 3 The LNG per hour exchanges heat with the first heat exchanger 2, and the temperature drops to -32.1°C, then enters the newly added second gasifier 3, and is transported to the downstream natural gas pipeline network. After exchanging heat in the first heat exchanger 2, the gas phase R404A at -25°C and LNG becomes a low-temperature liquid phase at -32.2°C and 0.2 MPa, with a flow rate of 25.5t / h, and flows into the liquid-phase low-temperature refr...

Embodiment 3

[0035] -161℃, 12500m 3 The liquefied natural gas per hour is gasified by the gasifier, and then becomes normal temperature natural gas and enters the natural gas pipeline network. The visibility in the gasification station was less than 6m in 60 minutes, and the staff could barely operate. The cold fog spread to the surrounding residential areas, reducing the ambient temperature; the cold fog spread to the surrounding roads, greatly reducing visibility and seriously affecting traffic.

[0036] -161℃, 0.4MPa, 12500m from LNG storage tank 1 3 The LNG per hour exchanges heat with the first heat exchanger 2, and the temperature drops to -45.9°C, then enters the newly added second gasifier 3, and is transported to the downstream natural gas pipeline network. The gaseous R404A at -23°C exchanges heat with LNG in the first heat exchanger 2, and then turns into a low-temperature liquid phase at -35°C and 0.2 MPa, with a flow rate of 34.5t / h, and flows into the liquid-phase low-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com