Control method and device of tobacco pneumatic drying air-heating furnace

A technology of airflow drying and control method, which is applied in the directions of drying gas arrangement, drying, drying machine, etc., can solve the problems of long adjustment process time, complicated technology, large energy consumption, etc., and achieves convenient inspection of working conditions and device structure. Simple, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

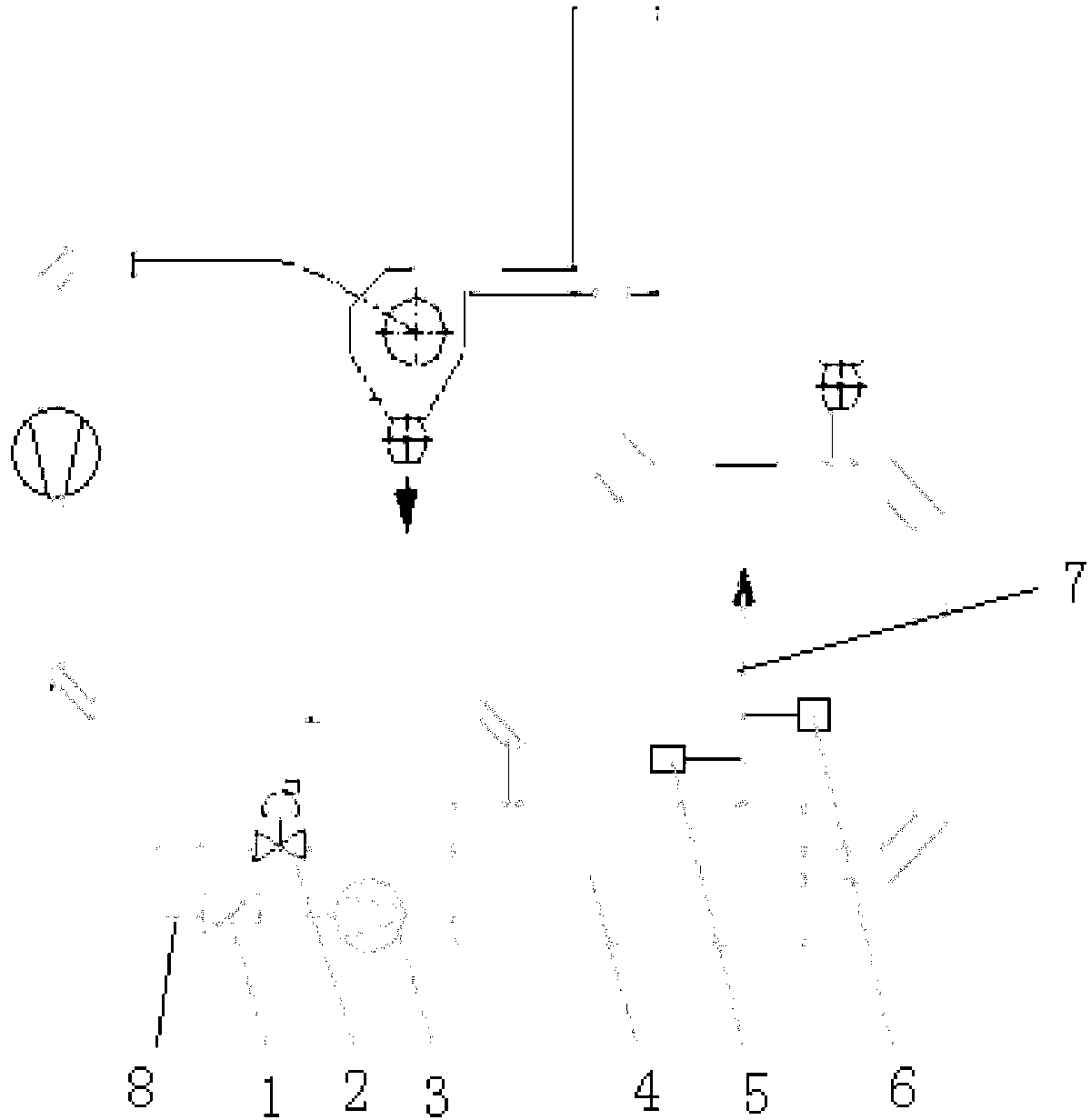

[0015] see figure 1 , the airflow drying hot blast stove 4 of the airflow drying device is equipped with a fuel regulating valve 2, an air distribution pipe 8, an air distribution fan 3 and a smoke exhaust pipe 7, and a CO detector 5 is installed on the exhaust pipe 7 of the airflow drying hot blast stove 4 and O 2 Detector 6, air distribution damper 1 is installed on air distribution pipeline 8, control system and CO detector 5, O 2 The detector 6 and the air distribution damper 1 are electrically connected to establish a chain control relationship.

[0016] see figure 1 , when the airflow drying hot blast stove 4 of the airflow drying device is in different power requirements, the fuel regulating valve 2 will be in different positions, and the CO detector 5 and O are installed on the exhaust pipe 7 of the airflow drying hot blast stove 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com