Shotgun handguard and barrel locking mechanism

A locking mechanism and barrel technology, applied in the field of shotguns, can solve the problems of reduced shooting accuracy, inconvenient repair and maintenance, and inconvenient relative positions of shotguns, and achieve the effects of convenient disassembly, simple structure, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

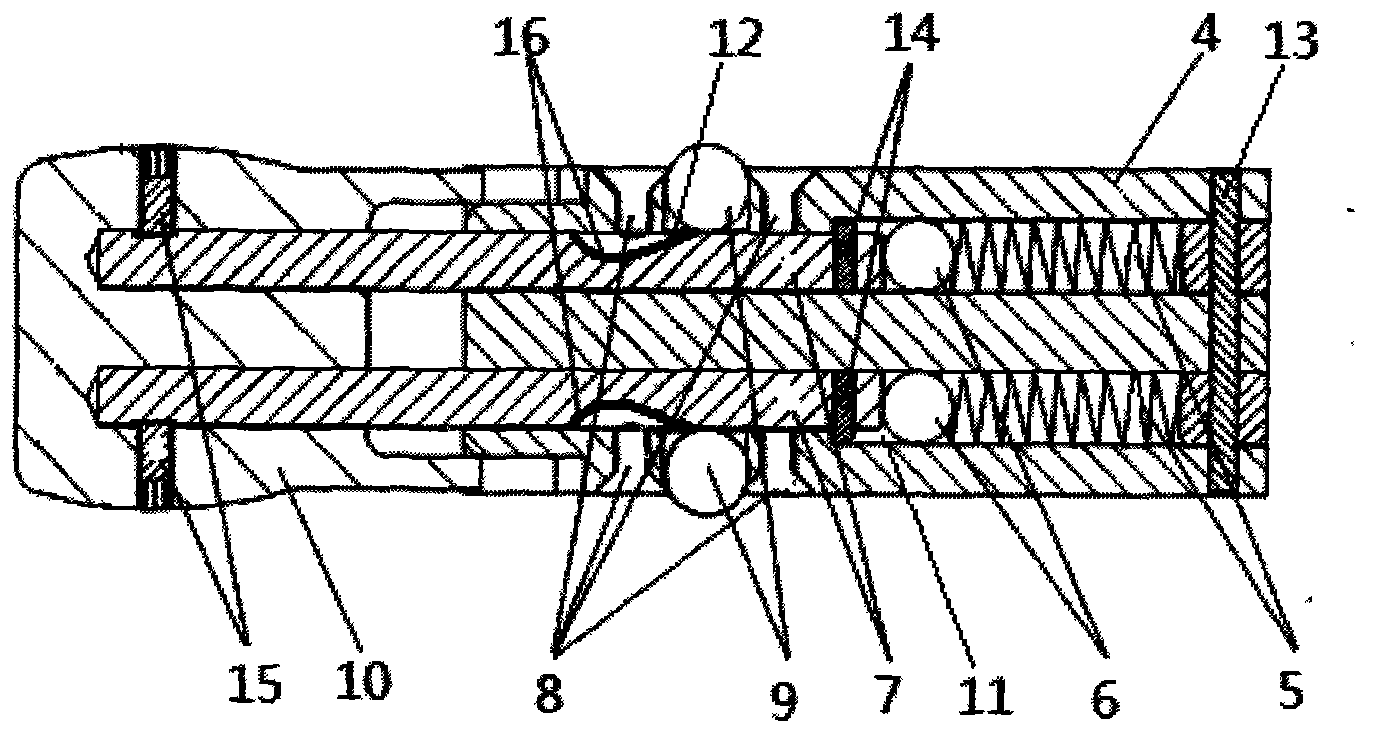

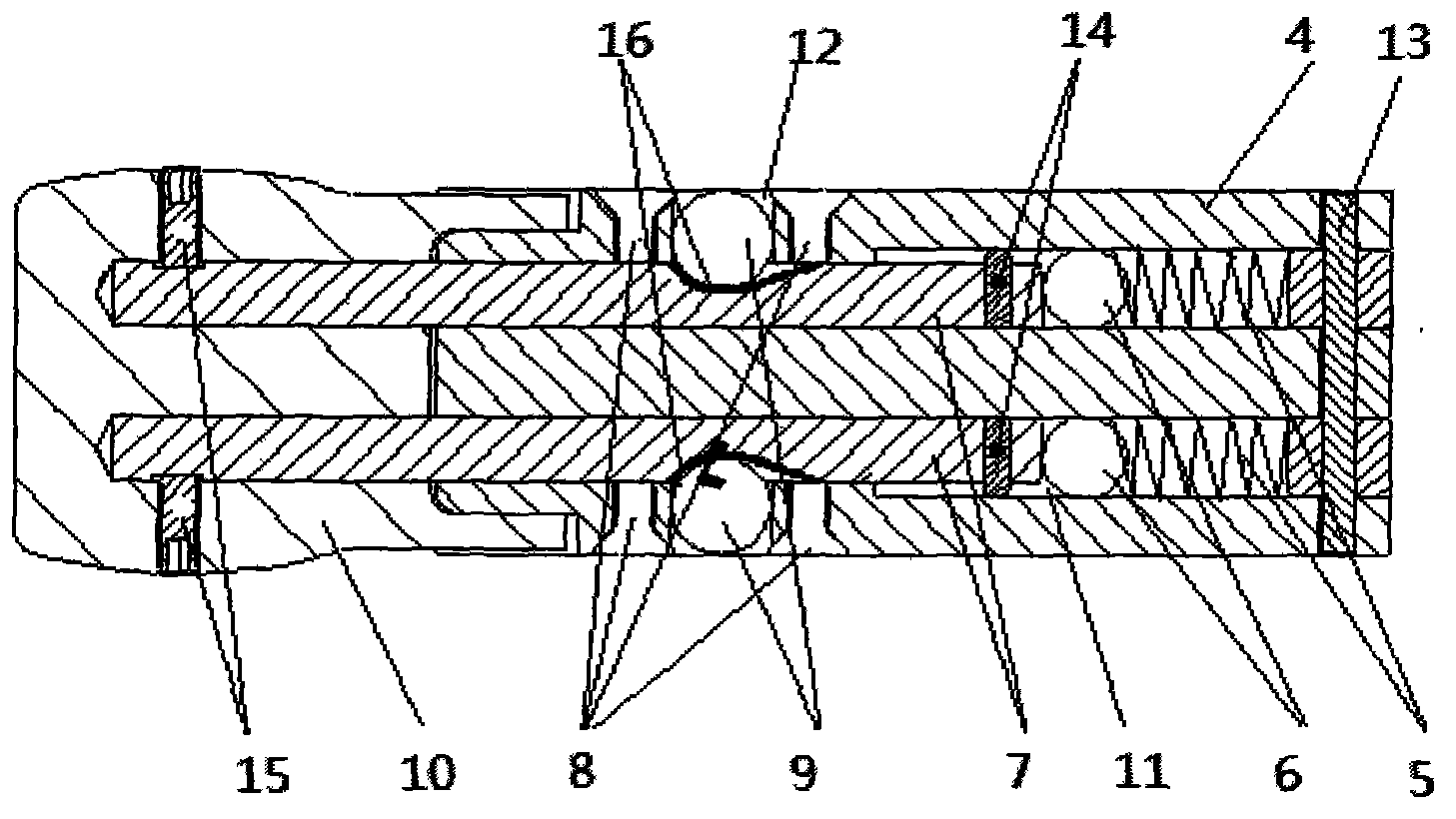

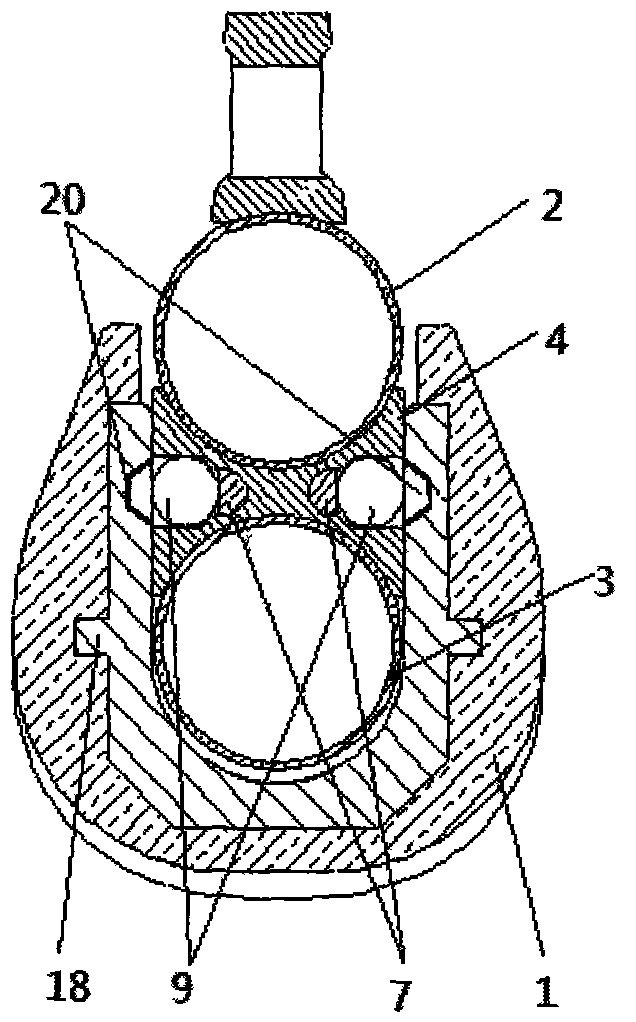

[0014] Depend on Figure 1-Figure 6 It can be seen that the present invention includes a handguard 1, an upper gun barrel 2, a lower gun barrel 3 and an intermediate fixing seat assembly, the upper gun barrel 2 and the lower gun barrel 3 are connected through an intermediate fixing seat assembly, and the middle fixing seat assembly includes a seat Body 4, spring 5, steel ball 6, handguard lock lever 7, countersunk screw group 8, locking steel ball 9 and handguard button seat 10, two ends of the seat body 4 are symmetrically provided with stepped holes 11, and there are The two sides of the middle part of the body 4 are symmetrically provided with a square groove 12 communicating with the stepped hole 11, and countersunk screw groups 8 are symmetrically installed on both sides close to the square groove 12, and the locking steel ball 9 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com