Thyristor power supply of gas laser

A technology of gas laser and silicon power supply, which is applied in the field of high-voltage generators and high-voltage excitation sources for gas discharge. It can solve the problems of large grid interference, low power factor, and large high-voltage DC ripple, etc., and achieve stable gas discharge, improve power factor, The effect of reducing the DC ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

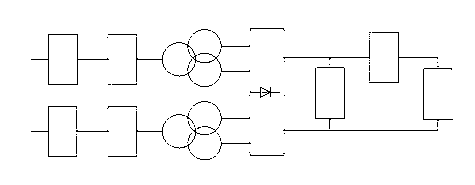

[0012] Such as figure 2 As shown, the two-way voltage regulating power supply is connected in series, one route is connected to the AC contactor 8, which is connected to the thyristor AC voltage regulating device 9, and the thyristor AC voltage regulating device 9 is connected to the three-winding step-up transformer 10, and the other route is connected to the AC contactor The thyristor 11 is connected to the thyristor AC voltage regulating device 12 , the thyristor AC voltage regulating device 12 is connected to the three-winding step-up transformer 13 , and the two-three winding step-up transformers 10 and 13 are connected to the high-voltage rectifier group 14 . The high-voltage rectifier group 14 is connected to the cathode of the discharge box 17 through the LC component 15, and the negative pole of the LC component 15 is connected to the cathode of the discharge box 17 through the resistance box 16, and the positive pole is directly connected to the anode of the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com