Mold-releasing oil automatic spraying device for aerated concrete block and method thereof

A technology of aerated concrete and automatic spraying, which can be applied to spraying devices with movable outlets, spraying devices, and devices that apply liquid to the surface, etc., which can solve the problems of large loss of mold release oil, high labor intensity, and inability to mold release. , to achieve the effect of improving product quality, reducing workload and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

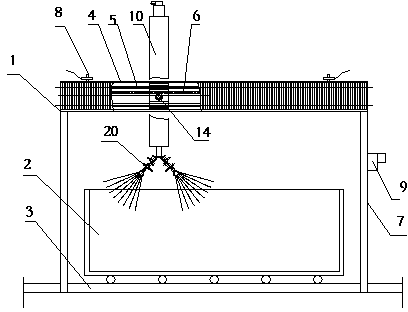

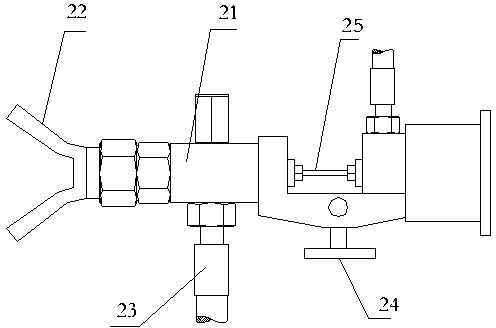

[0026] Such as figure 1 As shown, the automatic spraying device for aerated concrete block mold release oil of the present invention includes a spraying frame 1, and a mold box 2 accommodation space is left under the spraying frame 1, and a walking mechanism that can move horizontally and horizontally is provided on the spraying frame 1, and the walking mechanism An axially rotatable rotary mechanism 10 is vertically arranged on the mechanism, and a spray head 20 externally connected to a release oil atomizer is arranged at the lower end of the rotary mechanism 10 . The traveling mechanism moves on the beam 4 to drive the nozzle 20 to move, and during the movement, the nozzle 20 sprays the inner wall of the mold box 2, which saves manpower.

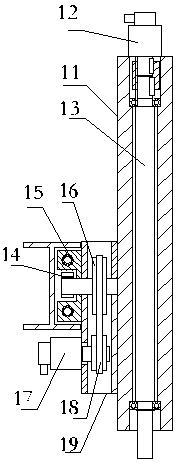

[0027] Specifically, the spraying rack 1 includes a column 7 and a beam 4 , and the beam 4 is provided with a horizontal rack belt 6 and a guide shaft 5 parallel to the rack belt 6 . Traveling mechanism comprises walking support 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com