Conical rod piece drive positioning tooling and cylindrical grinding machine

A technology for positioning tooling and rods, which is applied in the direction of grinding machines, machine tools designed for grinding the rotating surface of workpieces, manufacturing tools, etc. It can solve problems such as affecting cylindricity, workpieces and grinding wheels are not perpendicular, workpieces and tops cannot be completely overlapped, etc. To achieve the effect of improving the grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

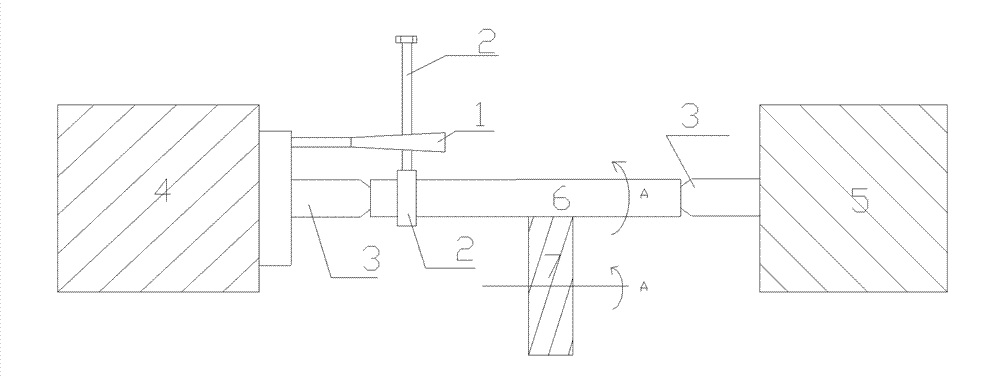

[0015] refer to figure 1 As shown, a conical rod drive positioning tool, such as figure 1 The driving rod 1 in the middle is a rod-shaped structure, one end of which is truncated conical, and the other end is a cylindrical rod, and one end of the cylindrical rod is fixedly connected to the upper bottom surface of the truncated conical rod (the upper surface of the truncated conical rod). The diameter of the bottom surface is smaller than the diameter of the bottom surface), and the cone angle of the truncated cone is 15°±30′.

[0016] refer to figure 1 Shown, a kind of cylindrical grinding machine, comprises the head box that is provided with drive wheel relatively, bed tail box, driving lever (or be referred to as shift fork) 1 and chuck 2, on the head box 4 and the tail box The adjacent surface of 5 is relatively provided with a top 3, the top abuts against the two ends of the cylindrical workpiece 6 to be ground, and the workpiece to be ground is positioned by the top,

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com