Tire electromagnetic induction vulcanization device

An electromagnetic induction, tire technology, applied in tires, applications, household appliances, etc., to achieve the effect of less energy consumption and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

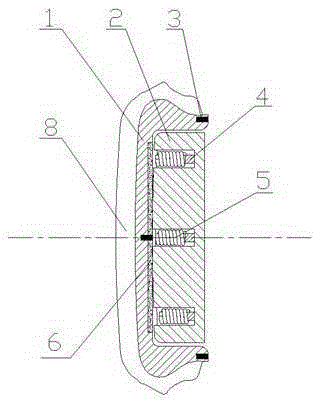

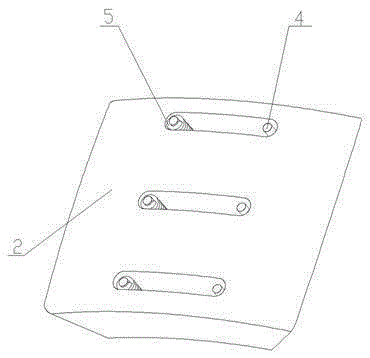

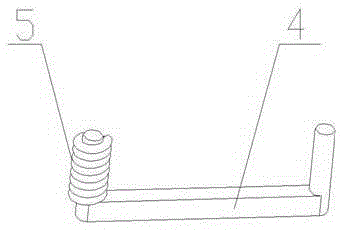

[0014] see figure 1 , figure 2 and Figure 5 , the present invention is provided with an expandable and contractible rigid metal inner mold, and the inner mold is composed of an expansion and contraction mechanism, n pieces of wide drum tiles 1, and n pieces of narrow drum tiles 7 (n is an integer not less than 5, and n is taken as 6 in this embodiment. ) and the drum tile rib plate 2 that is fixedly connected with it and plays a supporting role. There are transverse grooves on the surface of the drum tile rib plate that fits the wide drum tile and the narrow drum tile, and the drum tile that fits the drum tile A certain number of transverse grooves are opened on the surface of the rib plate 2, and the grooves are symmetrically and evenly distributed on the left and right sides of the transverse center line of the drum tile. Electromagnetic coils 5 are embedded in each groove, and each block is composed of a wide drum tile 1 and a narrow drum tile 7. The inductances of all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com