Preparation method of monoethanol diisopropanolamine

A technology of ethanol diisopropanolamine and diisopropanolamine, which is applied in the field of preparation of monoethanol diisopropanolamine, can solve problems such as unsatisfactory cement strength in the later stage, achieve short reaction time, high yield, and easy The effect of molecular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

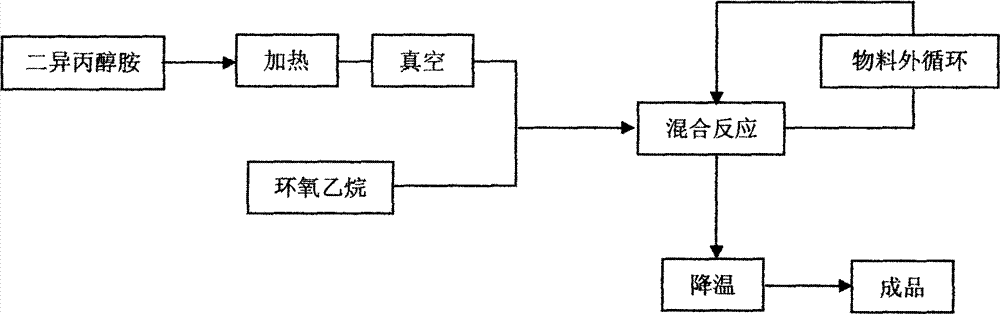

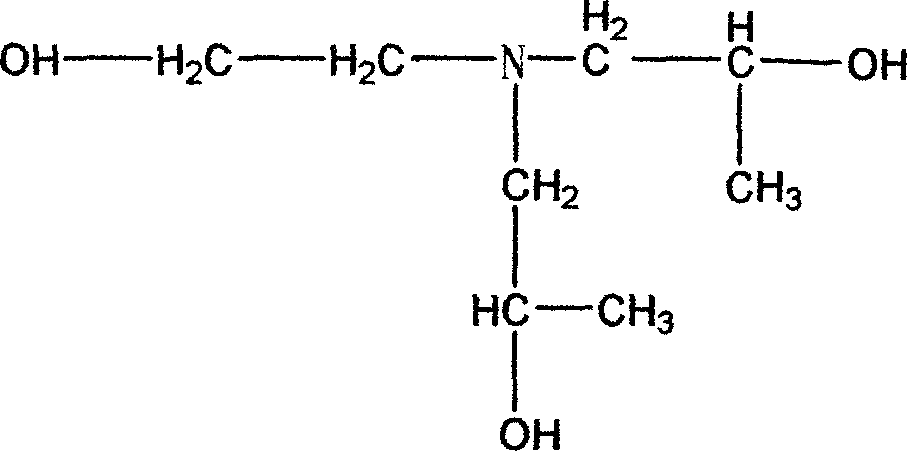

[0013] refer to figure 1 and figure 2 Shown, a kind of preparation method of monoethanol diisopropanolamine of the present invention, described monoethanol diisopropanolamine is made of diisopropanolamine (about 90% content) and oxirane in the reactor Gained after mixed reaction; its preparation steps are as follows:

[0014] a) Add 328.0 g of diisopropanolamine as a raw material into the reactor.

[0015] b) Heating the reaction kettle to a temperature of 70° C., then vacuumizing the inside of the reaction kettle, adding 88.0 g of raw material ethylene oxide in proportion, and performing a circular reaction at a temperature of 70° C. using an external circulation reactor for 5 hours to obtain Monoethanol diisopropanolamine, the yield of monoethanol diisopropanolamine is 89.7%.

[0016] c) After cooling down the monoethanol diisopropanolamine mixed solution obtained in step b), discharge and fill it.

Embodiment 2

[0018] refer to figure 1 and figure 2 Shown, a kind of preparation method of monoethanol diisopropanolamine of the present invention, described monoethanol diisopropanolamine is made of diisopropanolamine (about 90% content) and oxirane in the reactor Gained after mixed reaction; its preparation steps are as follows:

[0019] a) Add 295.6 g of raw material diisopropanolamine into the reactor.

[0020] b) Heating the reaction kettle to a temperature of 60° C., then vacuumizing the inside of the reaction kettle, adding 92.4 g of raw material ethylene oxide in proportion, and performing a circular reaction at a temperature of 60° C. using an external circulation reactor for 3 hours to obtain Monoethanol diisopropanolamine, the yield of monoethanol diisopropanolamine is 96.6%.

[0021] c) After cooling down the monoethanol diisopropanolamine mixed solution obtained in step b), discharge and fill it.

Embodiment 3

[0023] refer to figure 1 and figure 2 Shown, a kind of preparation method of monoethanol diisopropanolamine of the present invention, described monoethanol diisopropanolamine is made of diisopropanolamine (about 90% content) and oxirane in the reactor Gained after mixed reaction; its preparation steps are as follows:

[0024] a) Add 295.6 g of raw material diisopropanolamine into the reactor.

[0025] b) Heating the reaction kettle to a temperature of 65° C., then evacuating the inside of the reaction kettle, adding 114.3 g of raw material ethylene oxide in proportion, and performing a circular reaction at a temperature of 65° C. using an external circulation reactor for 2 hours to obtain Monoethanol diisopropanolamine, the yield of monoethanol diisopropanolamine is 95.8%.

[0026] c) After cooling down the monoethanol diisopropanolamine mixed solution obtained in step b), discharge and fill it.

[0027] The beneficial effect of the preparation method of monoethanol diiso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com