A kind of preparation method and application of low viscosity polyether type hyperbranched epoxy resin

An epoxy resin and polyether-based technology, applied in the field of coatings, can solve the problems of high viscosity of hyperbranched polyether and does not conform to the development trend of low-VOC environmental protection coatings, etc., to achieve reduced diffusion rate, controllable molecular structure, and less side reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

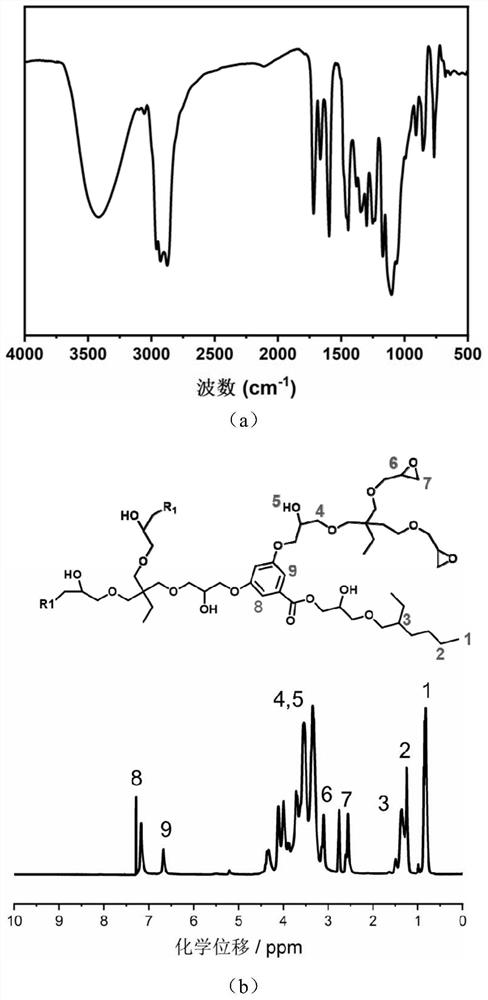

[0033] Embodiment 1: A kind of preparation method of polyether type hyperbranched epoxy resin

[0034] Dissolve 1.541g of 3,5-dihydroxybenzoic acid, 1.683g of octyl glycidyl ether and 0.161g of tetrabutylammonium bromide in 4mL of DMF, and react at 60°C for 5 hours under the protection of nitrogen. After the reaction, DMF was concentrated, the product was diluted with ethyl acetate, and the product was washed with NaHCO 3 solution was washed three times, then washed three times with saturated NaCl solution, and finally washed with water, anhydrous NaSO 4 Dried and spin-dried to obtain a light yellow liquid as A 2-1 monomer. Example 1 can use 9.071g of trimethylolpropane triglycidyl ether as B without purification 3 Monomer and 0.483g of tetrabutylammonium bromide, 40mL of DMF, add the reaction completed A at one time 2 In the monomer, the reaction was continued at 70° C. for 2 hours under the protection of nitrogen atmosphere. After the reaction is completed, precipitate ...

Embodiment 2

[0036] Example 2: In this example, on the basis of Example 1, the reaction time with trimethylolpropane triglycidyl ether is extended from 2 hours to 4 hours, and other conditions are as shown in Example 1. The obtained polyether The physical and chemical properties of type hyperbranched epoxy resin are shown in Table 1.

Embodiment 3

[0037] Example 3: In this example, on the basis of Example 1, the reaction time with trimethylolpropane triglycidyl ether is extended to 6 hours, and other conditions are as shown in Example 1, and the obtained polyether type hyperbranched The physical and chemical properties of epoxy resin are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com