A kind of polycarboxylate superplasticizer with high water reduction and high slump retention and preparation method thereof

The technology of a water reducing agent and polycarboxylic acid is applied in the field of high water reducing and high slump retention type polycarboxylate water reducing agent and its preparation field, which can solve the problems of uncontrollable molecular weight of polycarboxylic acid, general dispersibility of water reducing agent and complicated synthesis steps. and other problems, to achieve the effect of being conducive to large-scale industrial production, reasonable relative molecular weight distribution, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

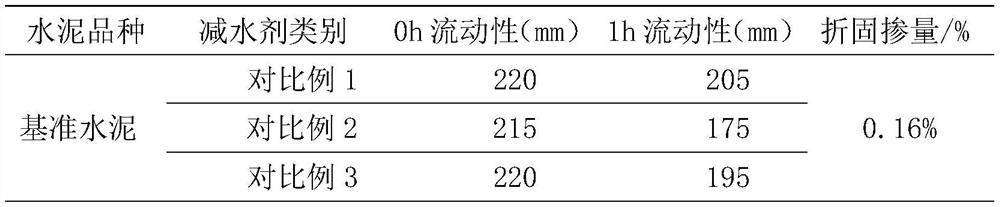

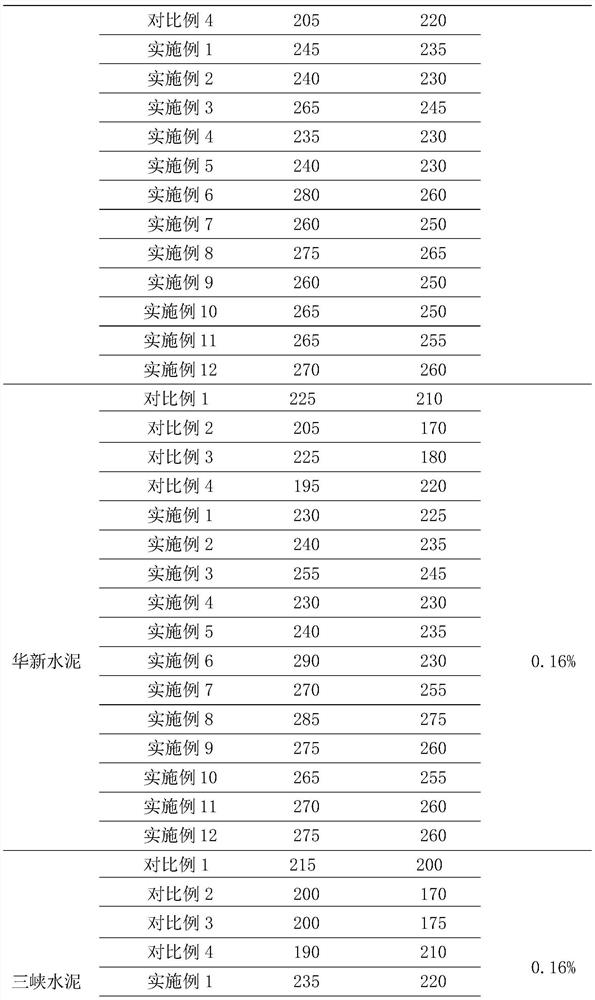

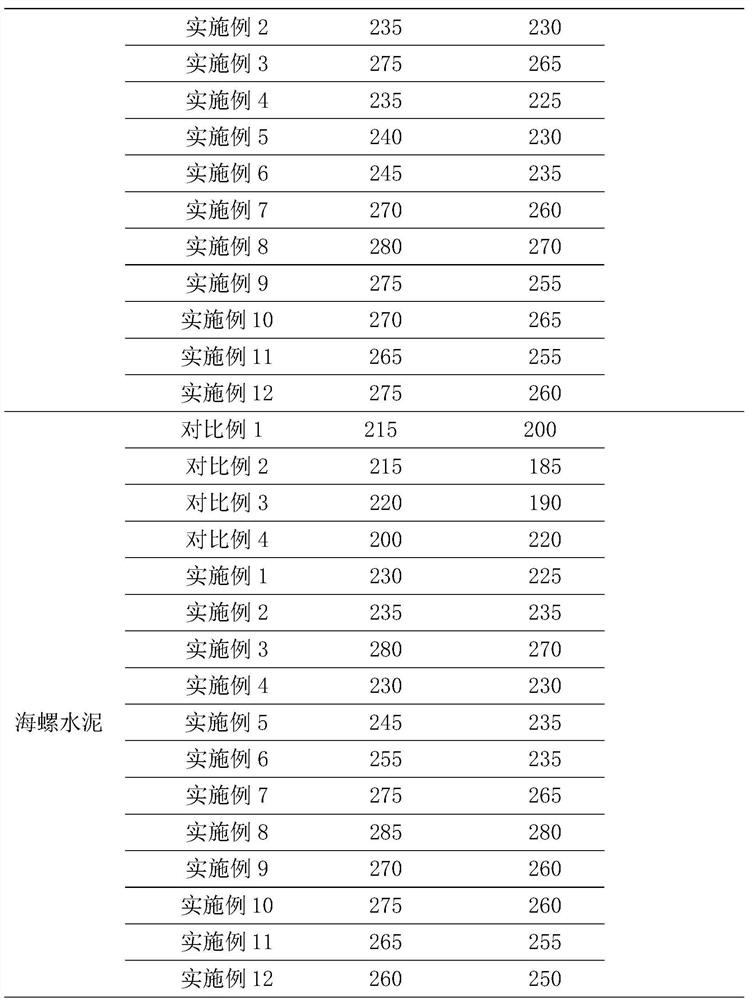

Examples

Embodiment 1

[0035] A high water-reducing and high-slump-preserving polycarboxylate water reducer, composed of 195 parts by mass of methallyl polyoxyethylene ether, 50 parts by mass of methacrylic acid and 10 parts by mass of dimethyl diallyl chloride The effect of the methyl methacrylate of ammonium chloride, 38 mass parts, the 2-bromopropionate methyl ester of 2 mass parts in the ferrous sulfate of 0.16 mass parts and the double (triphenylphosphine) nickel dibromide of 2 mass parts It is formed by atom transfer radical polymerization.

[0036] The preparation method of the above-mentioned high water reducing and high slump retention polycarboxylate water reducing agent comprises the following steps:

[0037] (1) Add the polyether monomer and water into the reaction vessel at a ratio of 1.28:1 by mass and number, stir evenly at room temperature to obtain a transparent solution, and add unsaturated monomer and unsaturated hydroxy ester monomer in sequence , after stirring for 15 minutes, ...

Embodiment 2

[0041]A high water-reducing and high-slump-retaining polycarboxylate water reducer, the difference from Example 1 is that it consists of 195 parts by mass of methallyl polyoxyethylene ether, 50 parts by mass of methacrylic acid and 10 parts by mass of Dimethyl diallyl ammonium chloride, the methyl methacrylate of 38 mass parts, the 2-bromo propionate methyl ester of 2 mass parts in the ferrous sulfate of 0.16 mass parts and the trimethylolpropane of 2 mass parts It is formed by atom transfer radical polymerization under the action of phosphite.

Embodiment 3

[0043] A high water-reducing and high-slump-retaining polycarboxylate water reducer, the difference from Example 1 is that it consists of 195 parts by mass of methallyl polyoxyethylene ether, 50 parts by mass of methacrylic acid and 10 parts by mass of Dimethyl diallyl ammonium chloride, the methyl methacrylate of 38 mass parts, the 2-bromo propionate methyl ester of 2 mass parts in the ferrous sulfate of 0.16 mass part and the trimethylolpropane of 1 mass part The phosphite and 1 mass part of bis(triphenylphosphine)nickel dibromide are formed through atom transfer radical polymerization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com