High-strength hot rolled steel plate roll for automobile wheels as well as preparation method thereof

A technology of hot-rolled steel plate and manufacturing method, applied in the direction of temperature control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Hereinafter, the high-strength hot-rolled steel sheet coil for automobile wheels and the manufacturing method thereof of the present invention will be described in detail with reference to exemplary embodiments.

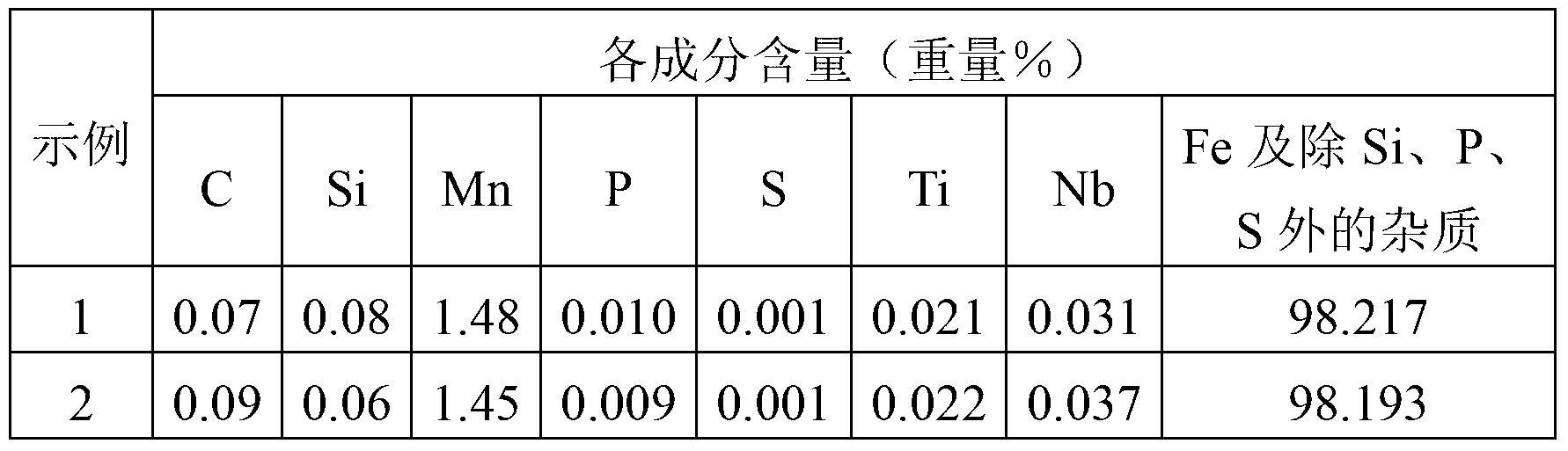

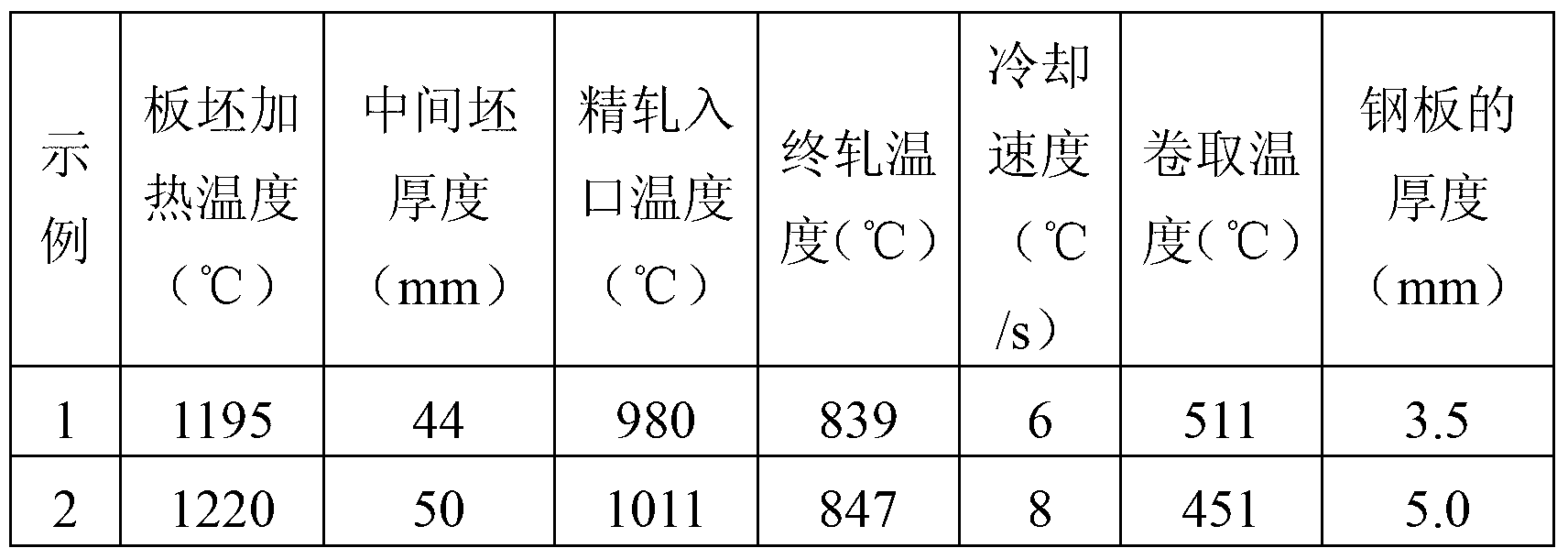

[0013] The manufacturing method of the high-strength hot-rolled steel sheet coil for automobile wheels of the present invention comprises the following steps: smelting target molten steel, the components of the target molten steel are 0.05-0.10% C, no more than 0.15% Si, 1.30 ~1.50% of Mn, no more than 0.15% of P, no more than 0.002% of S, 0.02~0.10% of Ti, 0.025~0.045% of Nb and the balance of Fe and unavoidable impurities; Target molten steel is continuously cast into a slab; heat the slab to 1180-1250°C; conduct rough rolling on the slab in 5 passes, and the single-pass reduction rate is not less than 20%; Finish rolling of the billet, the starting temperature of the controlled finish rolling is not higher than 1030°C, and the finish rolling temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com