Electrical control rectifying valve of hydraulic electric feed energy shock absorber

A technology of shock absorbers and rectifier valves, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., and can solve problems such as system malfunction, difficult maintenance and replacement, hydraulic energy loss, etc., to avoid energy loss , easy maintenance, and the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

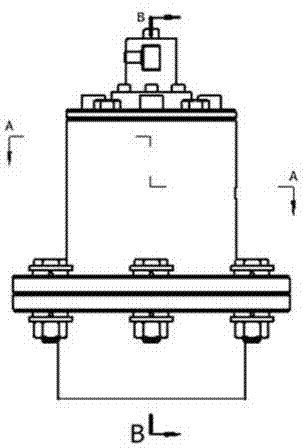

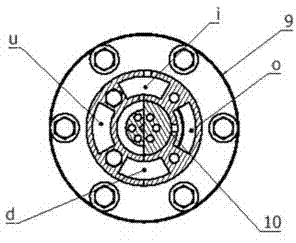

[0036]The purpose of the electronically controlled rectifier valve provided by the present invention is: it is specially designed for the hydraulic-electric energy-feeding shock absorber based on the integration of "mechanical-electric-hydraulic", and is used to rely on the upper and lower chamber pressure signals collected by the sensor according to the working requirements of the shock absorber. , to judge the flow characteristics of the liquid in the shock absorber, and drive the solenoid valve control valve to switch between the two working conditions through the control algorithm, rectify the flow direction of the liquid, and ensure that the flow direction of the output port is consistent.

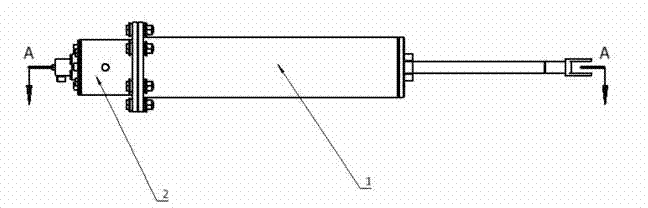

[0037] The electronically controlled rectifying valve of the hydraulic electric energy feed shock absorber provided by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com