Y-shaped frame sealing ring convenient to replace

A skeleton sealing ring and sealing ring technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of long replacement cycle, waste of manpower, material resources, damage of Y-shaped skeletonless sealing ring, etc., and achieve strength improvement , Facilitate quick installation and save replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

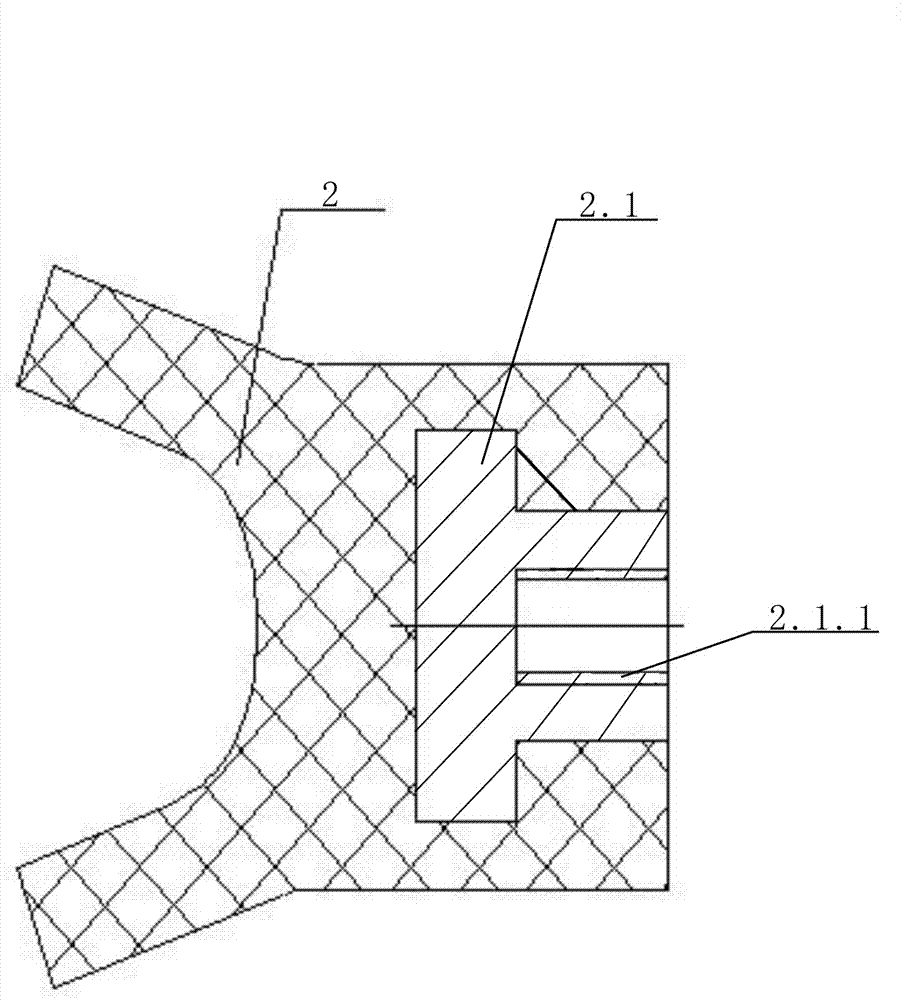

[0015] The invention is an easy-to-replace Y-shaped skeleton sealing ring. A T-shaped steel ring is inlaid in the Y-shaped skeleton sealing ring. The internal thread configured in the middle can easily pull out the damaged Y-shaped skeleton sealing ring from the hydraulic cylinder, saving replacement time and avoiding a lot of waste of manpower and material resources.

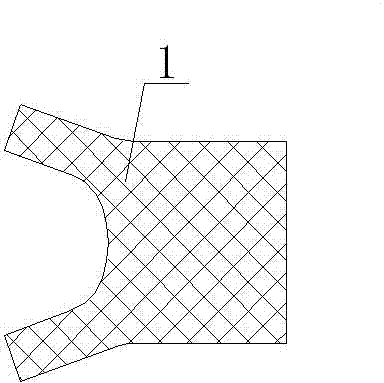

[0016] The Y-shaped skeleton sealing ring 2 of the present invention is an improved type of the Y-shaped non-skeleton sealing ring 1. One end of the Y-shaped non-skeleton sealing ring 1 has a square flat end and the other end has a semicircular cross-sectional structure. The sealing bracket, the square flat end and the two sealing brackets are all made of non-metallic materials.

[0017] The Y-shaped skeleton sealing ring 2 of the present invention has the same outline and structural dimensions as the Y-shaped non-skeleton sealing ring 1, so the Y-shaped skeleton sealing ring 2 can form a series of products acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com