Utility boiler heating surface design method applicable to flue-gas temperature deviation fixation

A flue gas temperature, power plant boiler technology, applied in the direction of combustion method, boiler water pipe, lighting and heating equipment, etc., can solve the problems of uneven flow, different pressure difference of parallel pipes, uneven heat absorption of pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

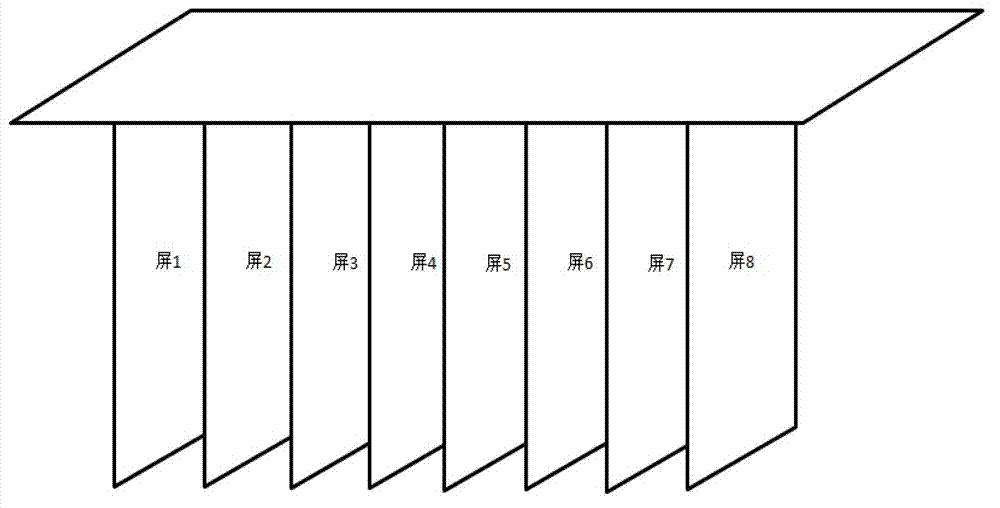

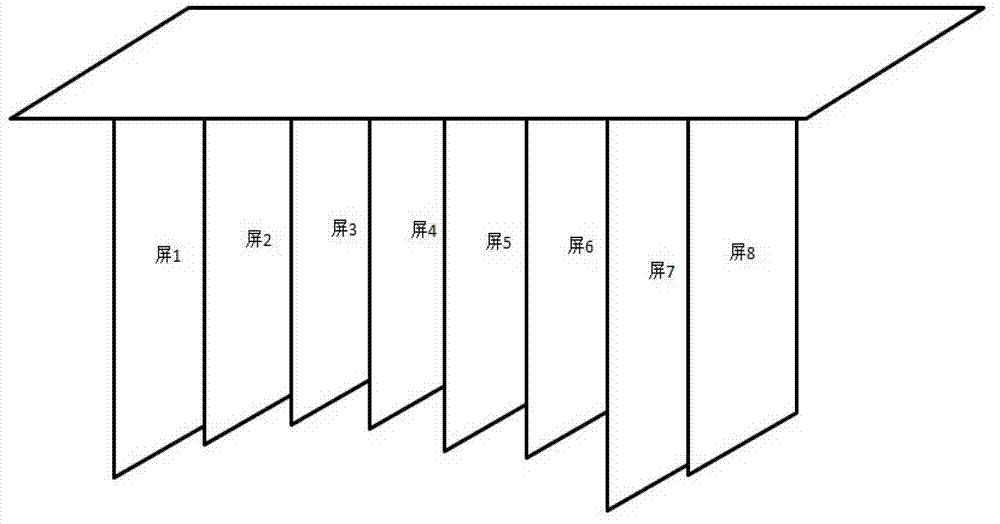

[0035] Example: In the horizontal flue, take 8 screens as an example, assuming that each screen has the same size and material, and the way of introducing and leading out of the header is the same.

[0036] The first step is to determine the flue gas temperature deviation coefficient of each screen according to the flue gas side temperature deviation curve on the same section;

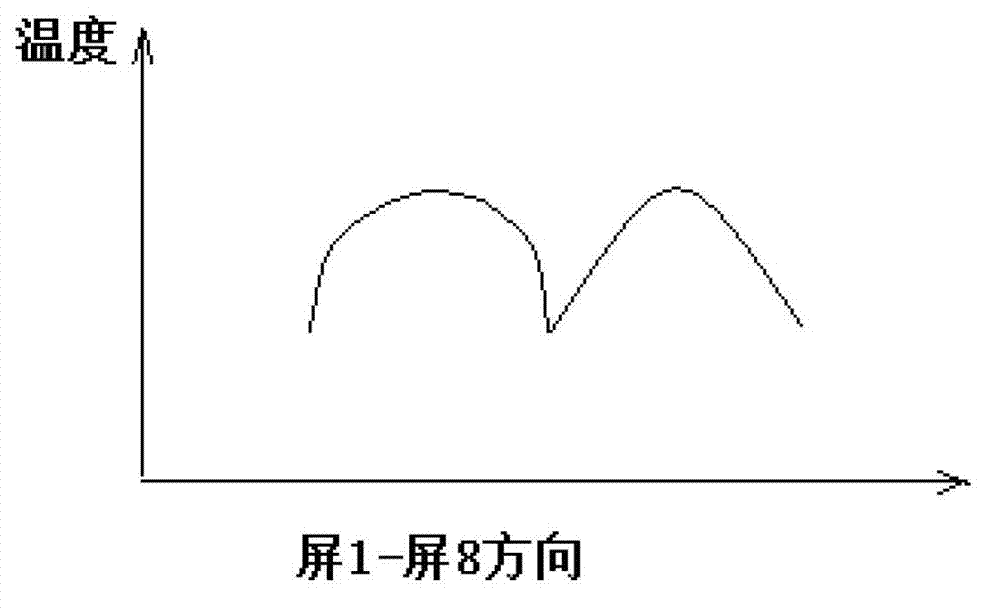

[0037] like image 3 Shown is a schematic diagram of the temperature deviation curve on the flue gas side. In addition, in order to facilitate understanding, a table is imagined below, and the approximate data is put into the table.

[0038] Table 1

[0039] Location Screen 1 Screen 2 Screen 3 screen 4 Screen 5 Screen 6 Screen 7 Screen 8 Flue gas temperature ℃ 1120 1130 1150 1125 1105 1120 1150 1100 Flue gas temperature deviation coefficient α 0.9956 1.0044 1.0222 1 0.9822 0.9956 1.0222 0.9777

[0040] As shown in Table 1, the average temperatu...

Embodiment 2

[0068] Embodiment 2 is the same as the first three steps of embodiment 1. After obtaining the comprehensive deviation coefficient, improve the material grade of the screen with large deviation to resist the possible deviation. This method does not eliminate the actual deviation, but the personalized design can ensure a certain degree of safety while ensuring safety. economy.

[0069] The fourth step is to adjust the material selection of the heating surface and design the deviation screen by calculating the coefficient of the flue gas deviation on the same section and the steam deviation between the screens. The screen with a large deviation can choose a good material, and the screen with a small deviation can be slightly inferior.

[0070] As shown in Table 4, if the comprehensive deviation of the screen is less than 1, it is a negative deviation, and if it is greater than 1, it is a positive deviation. Whether it is a positive deviation or a negative deviation, the greater t...

Embodiment 3

[0073] Embodiment 3 is the same as the first three steps of Embodiment 1.

[0074] The fourth step, after obtaining the deviation coefficient, we can adjust the design resistance of each screen through the size of the opening on the header, so as to adjust the flow rate of each screen to offset the difference caused by the deviation of flue gas and steam. The deviation between the screens is formed to obtain a more uniform outlet temperature.

[0075] like Figure 4 As shown, the working fluid enters the inlet header 1 from both ends, and a hole is opened on the header, and a pipe joint 3 is welded on the hole, and the pipe joint 3 is connected to the pipe 4 on the heating surface. The opening is large, and the inner diameter of the pipe joint is correspondingly large. The working fluid enters the outlet header 2 after being heated on the heating surface, and flows out from both ends of the outlet header. When the opening becomes larger, the inner diameter of the pipe joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com