Sterilizing and drying box with layered structure

A technology of hierarchical structure and drying box, which is applied to the dryer of static materials, drying chamber/container, drying gas arrangement, etc., can solve the load of increasing the heating power in the high temperature section, difficult to dry medicine bottles, waste of human resources, etc. problems, to achieve the effect of increasing the air level, saving human resources, and saving enterprise resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

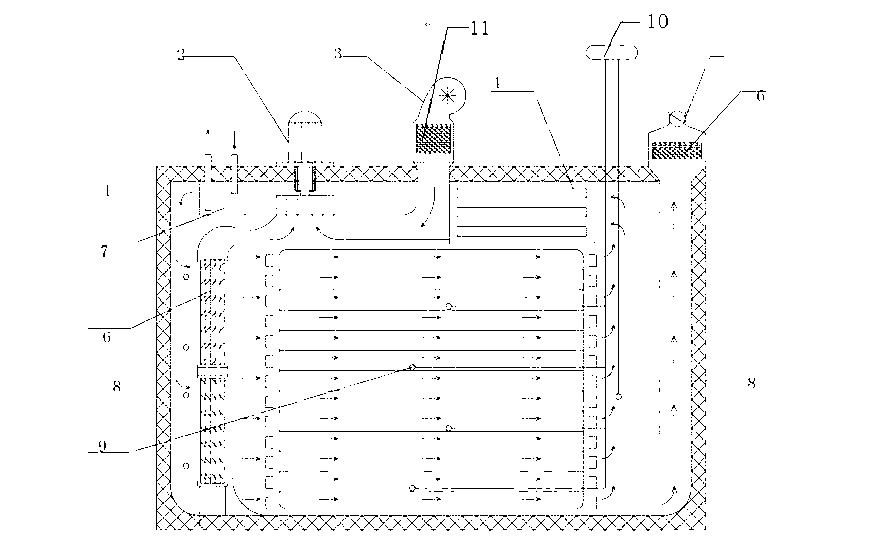

[0014] This embodiment provides a hierarchical structure of sterilization drying box, the structure is as follows: figure 1 Shown: It includes a box body 1, a thermal cycle device, a cooling box 7 and an electrical control device.

[0015] The box body 1 is a hollow stainless steel cavity, including an outer shell, an insulating layer and an inner container arranged sequentially from outside to inside. The outer shell is 4 layers of adjustable mesh panels, and the thickness of the insulating layer is 100mm. The box body 1 has a built-in desktop drying car and a baking tray arranged on the drying car in a hierarchical structure; the thermal cycle device includes a heater 4, an internal circulation fan 2, a blower 3 and a convection wall micro-adjustment plate 8, The heater 4 is fixed on the inner wall of the box 1 . In this embodiment, an air outlet is provided on the side wall of the box body 1, and an air outlet filter 6 is arranged at the air outlet.

[0016] The internal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com