Small liquefied natural gas vaporizer

A technology of liquefied natural gas and vaporizer, applied in the direction of heat exchanger type, indirect heat exchanger, fixed tubular conduit assembly, etc., can solve the problems of large heat source fluid flow rate, affecting vaporization efficiency, increasing intermediate medium shell, etc. High thermal efficiency, wide application range, and low cooling energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

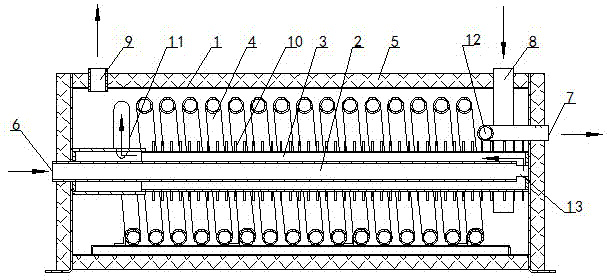

[0027] as attached figure 1 As shown, the small liquefied natural gas vaporizer of the present invention is mainly composed of a shell 1 , an inner tube 2 , a sleeve 3 and a coil 4 .

[0028] The shell 1 with the insulation layer 5 is provided with an LNG inlet 6 , an NG outlet 7 , a refrigerant inlet 8 and a refrigerant outlet 9 . The inner tube 2 , the sleeve tube 3 and the winding tube 4 are all fixed in the casing 1 .

[0029] The inner tube 2 is fixed in the middle of the housing 1 , and the casing 3 and the winding tube 4 are sequentially sleeved on the outside of the inner tube 2 . A heat exchange fin 10 is fixed on the outer wall of the casing 3 .

[0030] The outer end of the inner pipe 2 is connected to the LNG inlet 6 , and its insertion end 13 communicates with the casing 3 . The end of the casing 3 away from the insertion end 13 of the inner tube communicates with the medium inlet end 11 of the winding tube 4 . The medium output end 12 of the winding pipe 4 co...

Embodiment 2

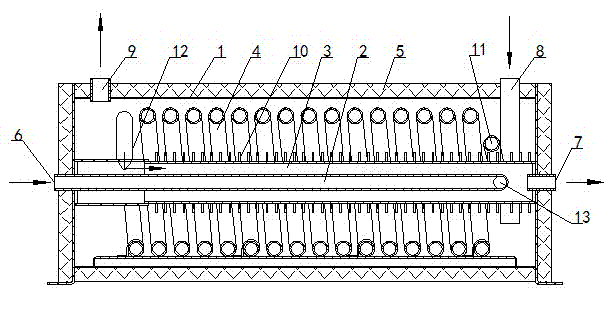

[0033] as attached figure 2 As shown, the small liquefied natural gas vaporizer of the present invention is mainly composed of a shell 1 , an inner tube 2 , a sleeve 3 and a coil 4 .

[0034] The shell 1 with the insulation layer 5 is provided with an LNG inlet 6 , an NG outlet 7 , a refrigerant inlet 8 and a refrigerant outlet 9 . The inner tube 2 , the sleeve tube 3 and the winding tube 4 are all fixed in the casing 1 .

[0035] The inner tube 2 is fixed in the middle of the housing 1 , and the casing 3 and the winding tube 4 are sequentially sleeved on the outside of the inner tube 2 . A heat exchange fin 10 is fixed on the outer wall of the casing 3 .

[0036] The outer end of the inner pipe 2 is connected to the LNG inlet 6 , and its insertion end 13 communicates with the medium inlet end 11 of the winding pipe 4 . The medium output end 12 of the winding tube 4 communicates with the end of the casing 3 away from the insertion end 13 of the inner tube. One end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com