LED flip-chip testing machine and testing method

A LED chip and chip testing technology, which is applied in the direction of single semiconductor device testing, etc., can solve the problems that cannot reflect the advantages and disadvantages of the flip-chip LED chip process, cannot provide the basis for light and color separation of test data, and flip-chip LED chips cannot provide objective and reliable testing. Data and other issues, to achieve high utilization, low equipment cost, high selectivity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

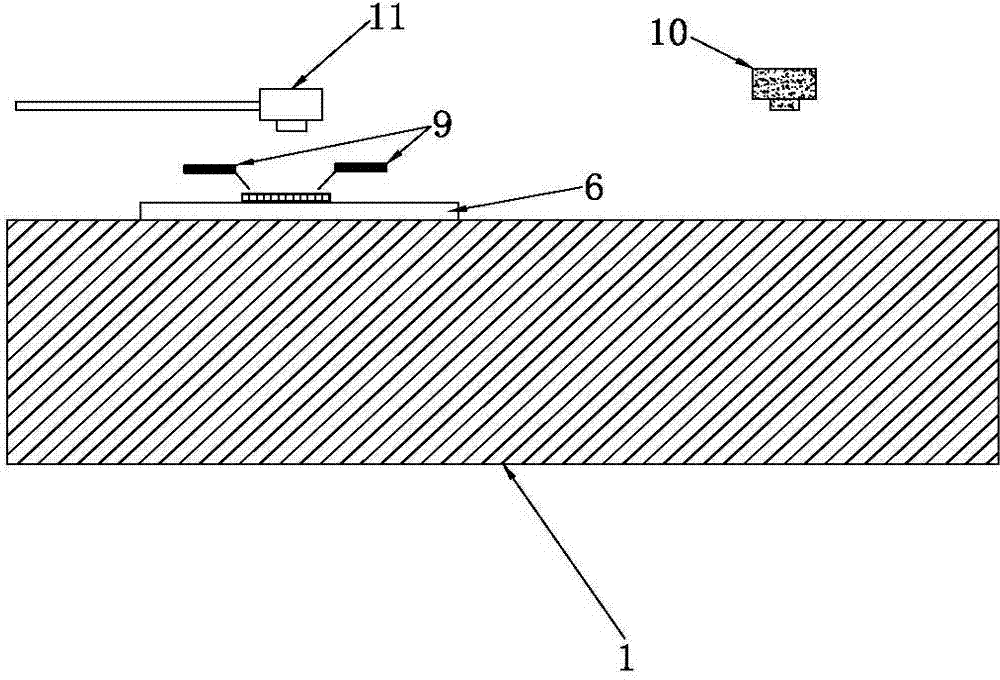

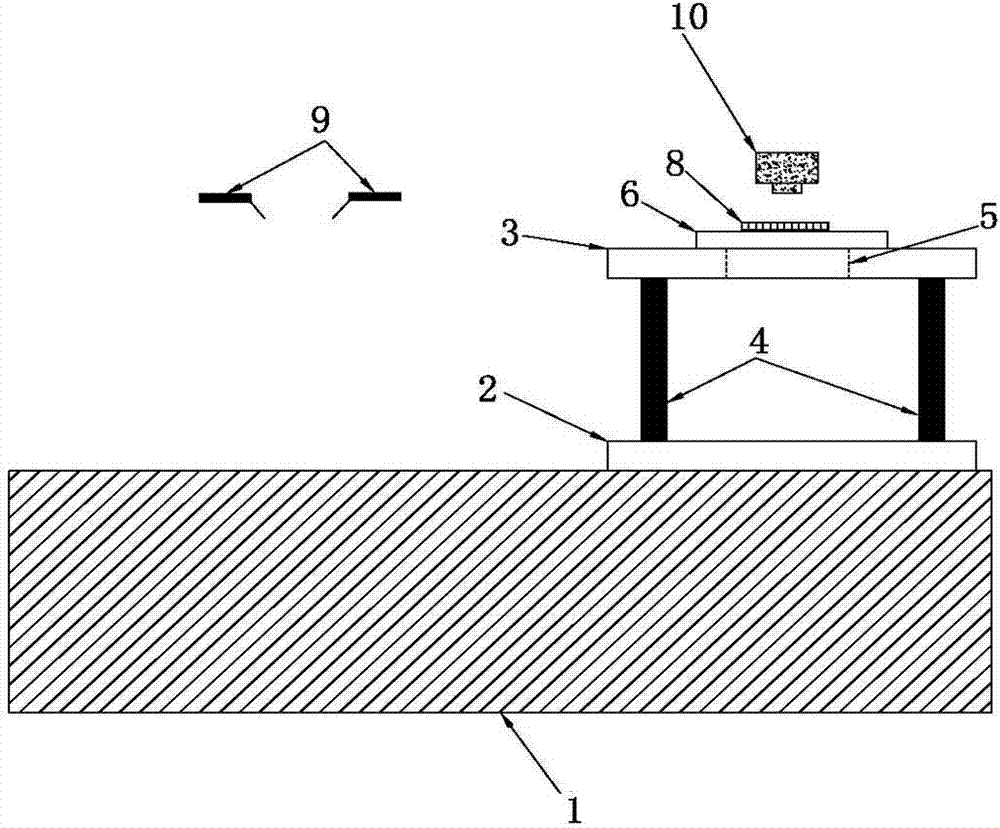

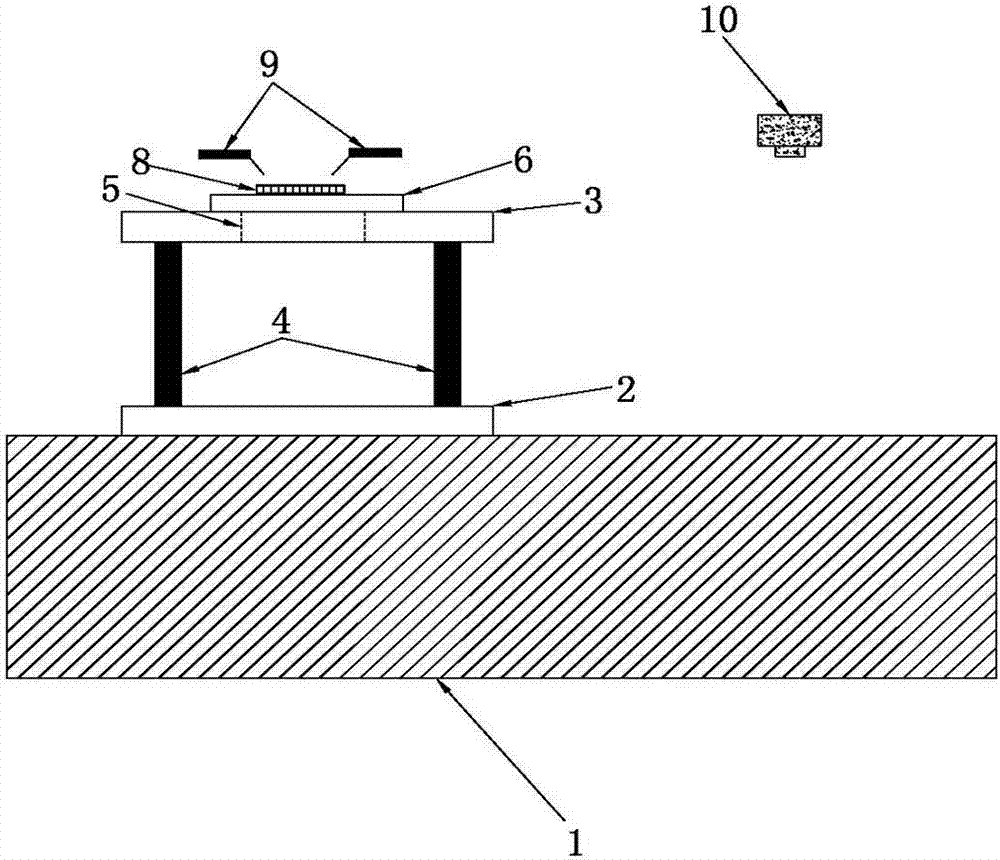

[0026] Such as figure 1 Shown is a schematic diagram of the structure of a traditional front-mounted LED chip testing machine. A flip-chip LED chip testing machine created by the present invention is formed by refitting the traditional front-mounted LED chip testing machine. Such as Figure 2-5 Shown is the testing machine created by the present invention, the flip-chip LED chip testing machine includes a chip loading device, a chip testing device and a flat solar panel 11, the chip testing device includes a probe 9, the contact direction of the probe 9 is downward, and the probe The needle 9 is used to connect the electrode of the LED chip to be tested to make the LED chip emit light; the chip loading device includes a working disc 6 for placing the flip-chip LED chip 8 to be tested and an XYZ three-axis driving device 1, and a support is provided under the working disc 6 The working disk 6 is connected to the XYZ three-axis driving device 1 through the supporting part. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com