Matched tooth designing method of torque-branching transmission gear train

A design method and technology of split torsion transmission, which can be applied to transmission devices, gear transmission devices, belts/chains/gears, etc., and can solve problems such as poor operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

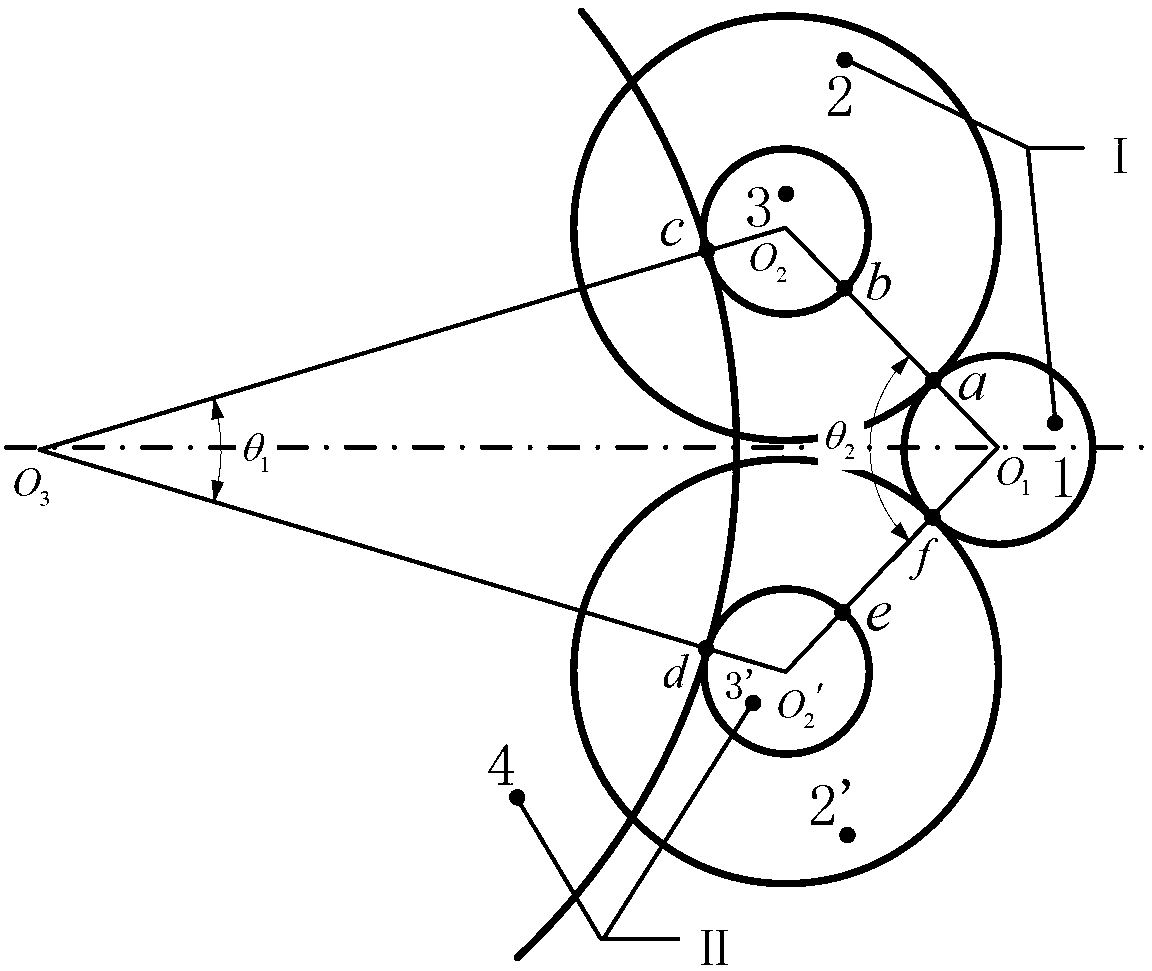

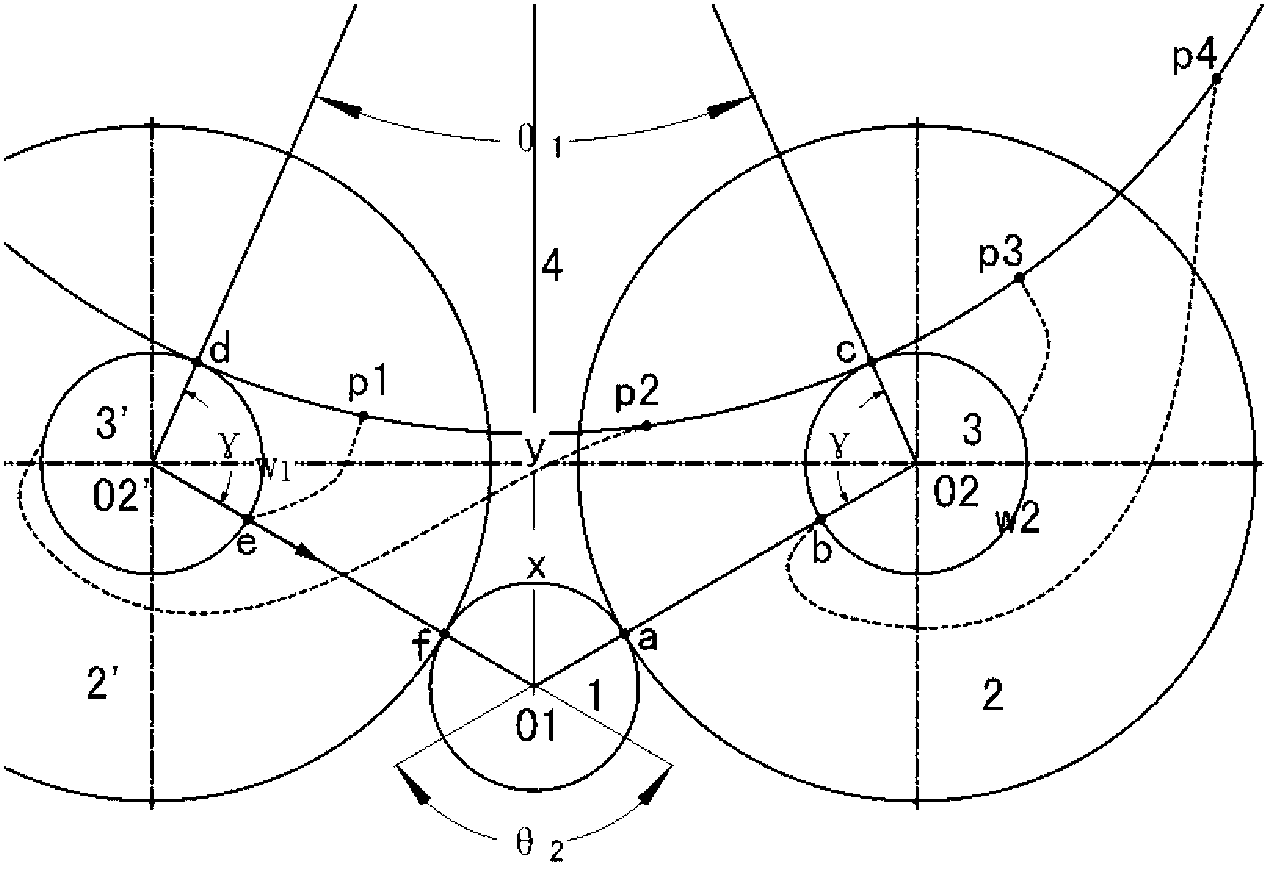

[0071] refer to figure 1 -7. Design a gear reduction box with two-stage split torsion transmission, and its gear train configuration is as follows: input stage pinion gear 1 meshes with input stage right branch large gear 2 and input stage left branch large gear 2′, and output stage right branch gear 2′ meshes simultaneously. The branch pinion 3 and the left branch pinion 3' of the output stage mesh with the large gear of the output stage simultaneously. The large gear 2 of the right branch of the input stage and the small gear 3 of the right branch of the output stage form a double gear, the large gear 2' of the left branch of the input stage and the small gear 3' of the left branch of the output stage form a double gear, and the two double gears interchangeable. It is known that the input power is 100kW, the input speed is 3000r / min, the output speed is 200r / min, the gear material is 20CrMnTi, carburized and quenched, and the precision is 6.

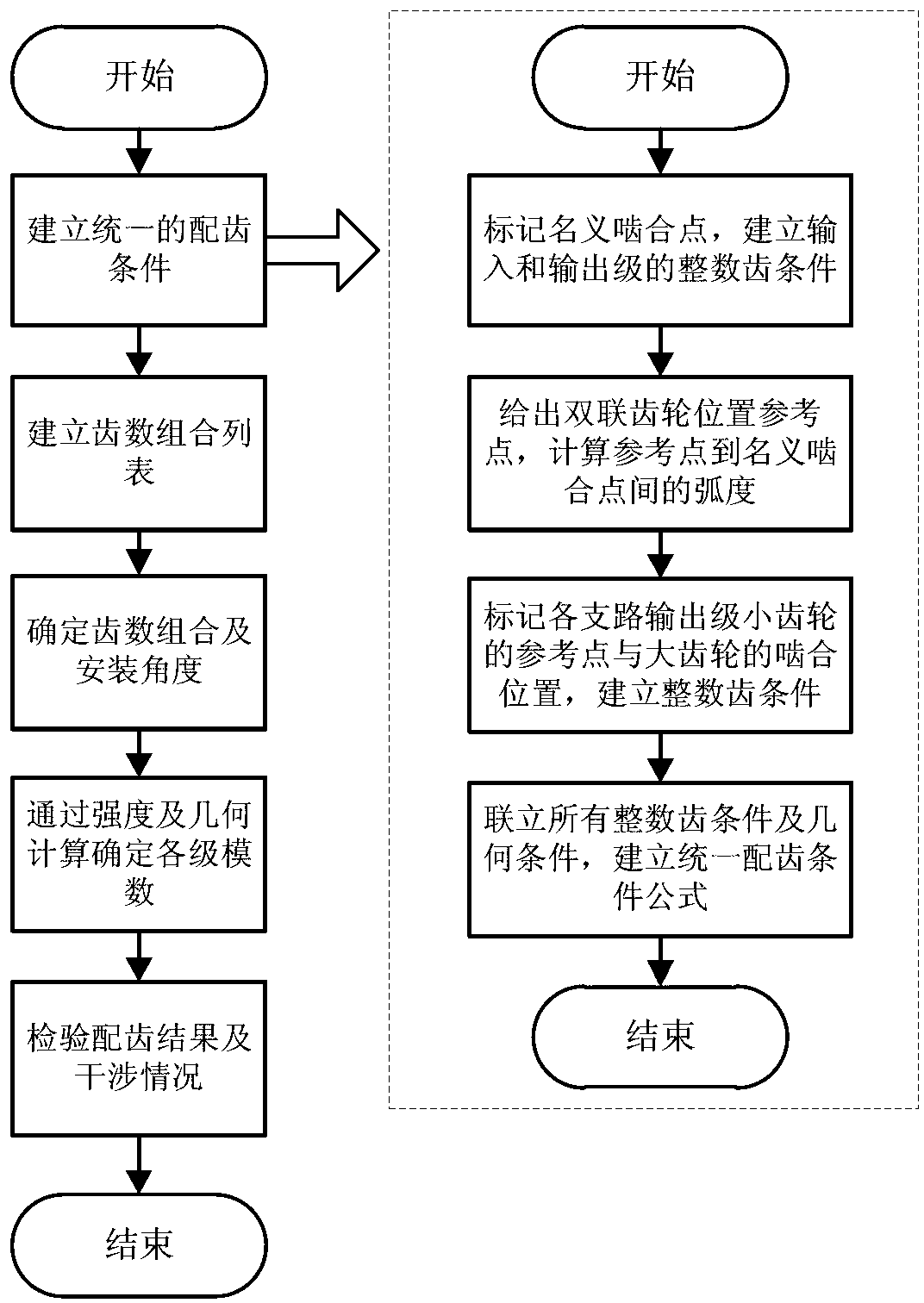

[0072] Step 1: Establish a u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com