A low pressure drop anti-foreign matter fuel assembly down tube seat

A fuel assembly and foreign matter prevention technology, which is applied in the directions of reactor fuel elements, fuel element assembly, nuclear power generation, etc., can solve problems such as abrasion and damage of fuel rod cladding, and achieve the balance of foreign matter prevention functions, uniform flow distribution, and pressure drop balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The lower nozzle of the low-pressure-drop anti-foreign matter fuel assembly according to the present invention will be further described below with reference to the drawings and specific embodiments.

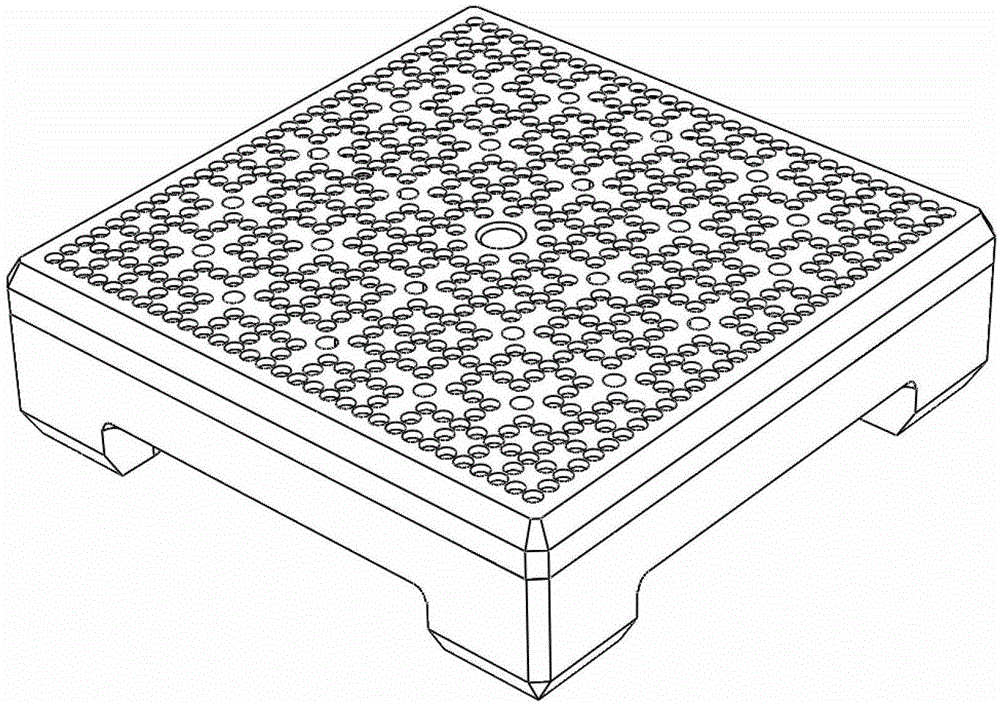

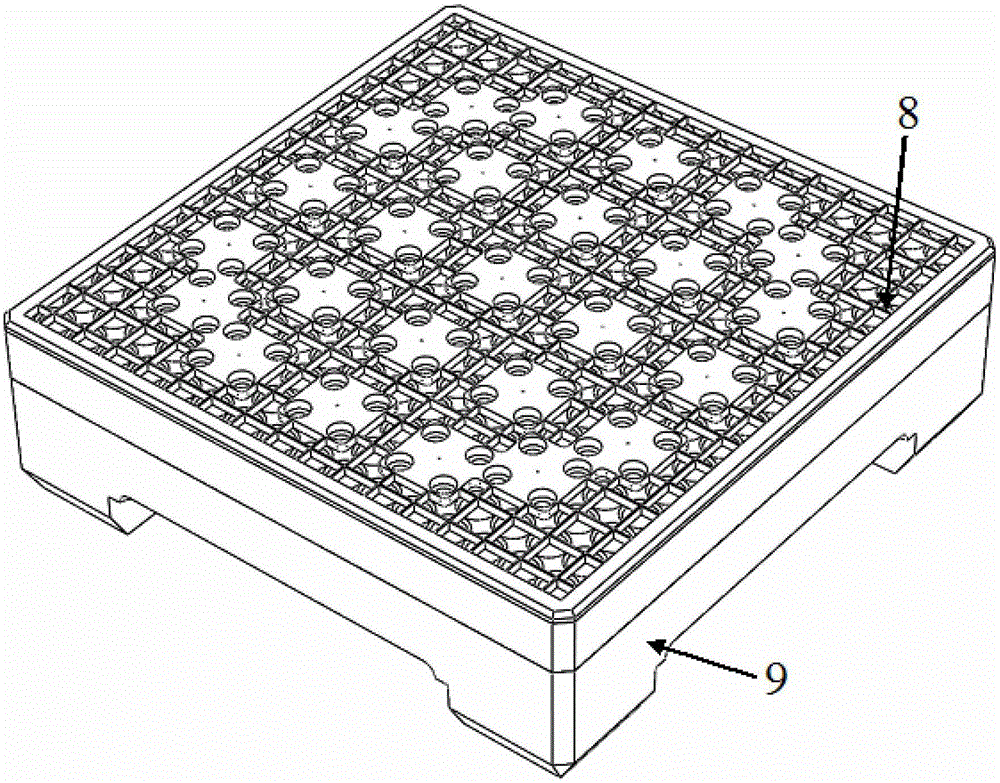

[0024] A fuel assembly lower nozzle base according to the present invention includes a support frame 9 and a lower nozzle grid plate 8 welded and fixed above the support frame 9 .

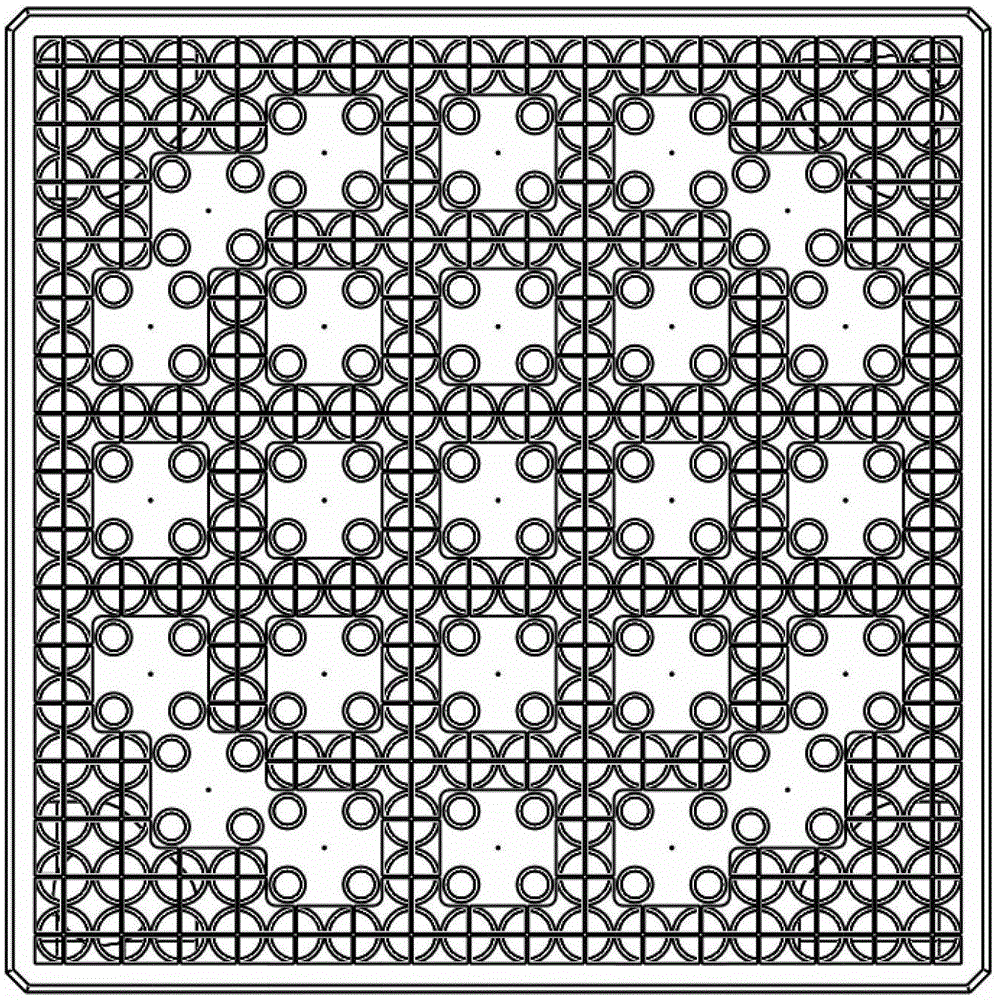

[0025] The lower pipe seat grid plate 8 includes two layers of plates, one of which is a large hole plate, and the other layer is a grid plate arranged above or below the large hole plate. The grid plate and the large hole plate are fixed together by welding or riveting.

[0026] Such as Figure 4 As shown, the grid plate is a mesh grid structure composed of vertical sheets. The grid plate may be provided with a connecting plate 3 at a position corresponding to each guide pipe and instrument pipe. A small flow hole 4 is respectively provided at the four corners of each connecting plate 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com