Building porcelain plate curtain wall dry hanging assembly and structure and construction method of building porcelain plate curtain wall dry hanging structure

A porcelain and plate technology, applied in building components, building structures, buildings, etc., can solve the problems of heavy plane plate weight, large dry hanging load, weakened strength, etc. Longevity, the effect of reducing the risk of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

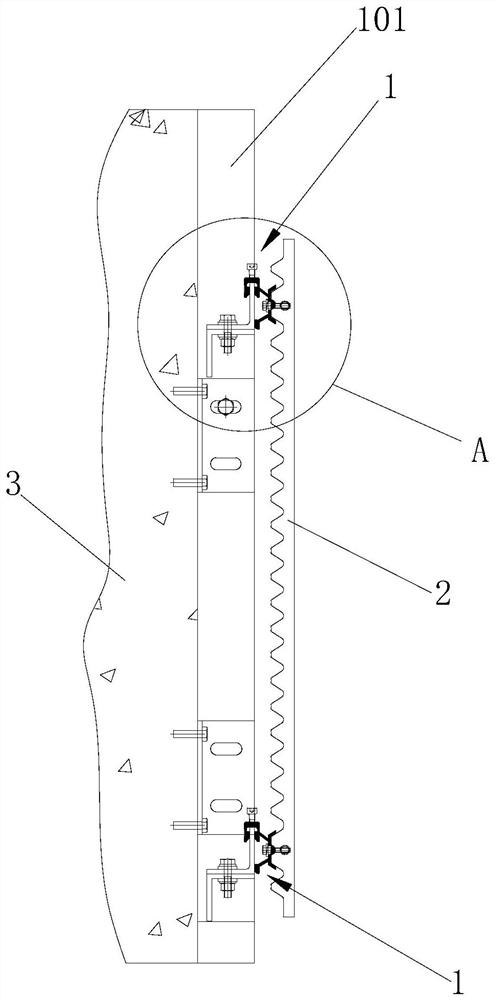

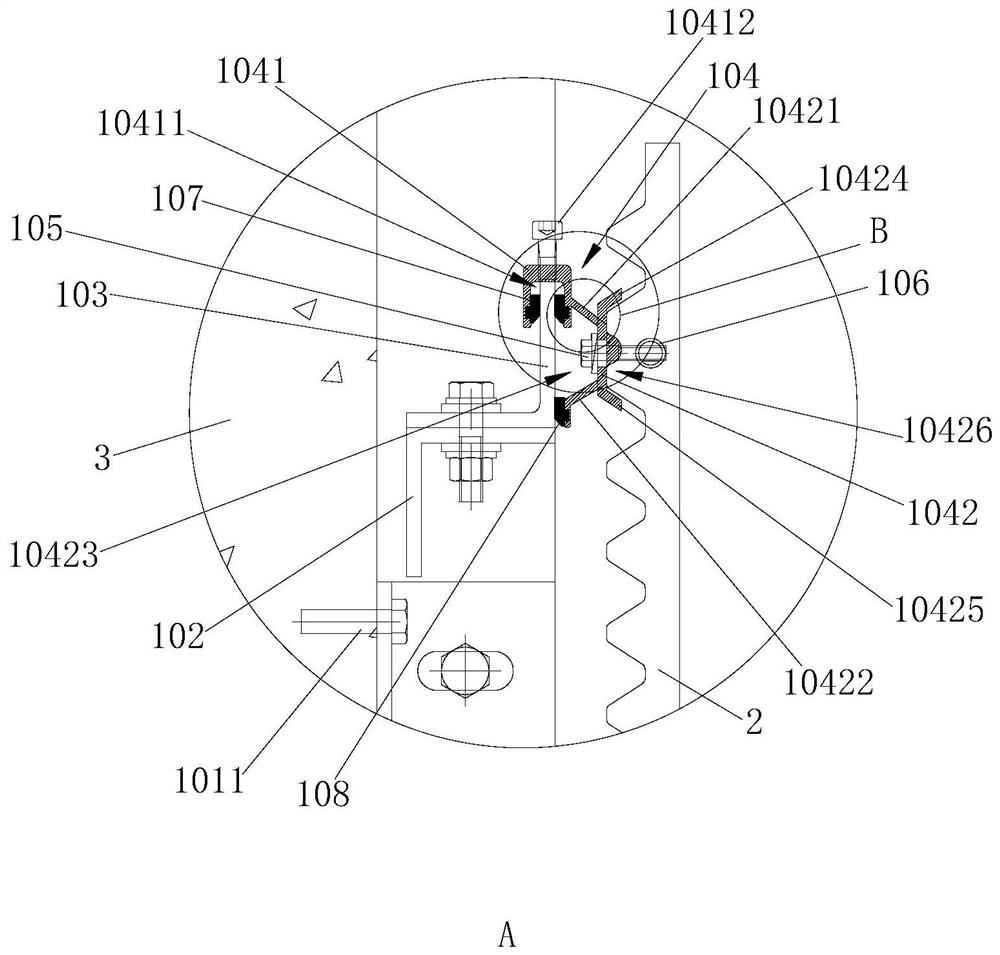

[0064] refer to Figure 1~4 , this embodiment discloses a dry-hanging component 1 for architectural porcelain plates, comprising a longitudinal keel 101, a horizontal beam 102, a right-angle corner bracket 103, and a hook 104. The horizontal beam 102 is fixed to the longitudinal keel 101 and is perpendicular to the longitudinal keel 101. Direction arrangement: the right-angle corner bracket 103 is fixed on the horizontal beam 102, the hook 104 is hooked on the right-angle corner bracket 103, the longitudinal keel 101 is connected to the wall at the position to be mounted through the connection component 1011, and the connection component 1011 can be a bolt and nut component , bolts can be anchor bolts;

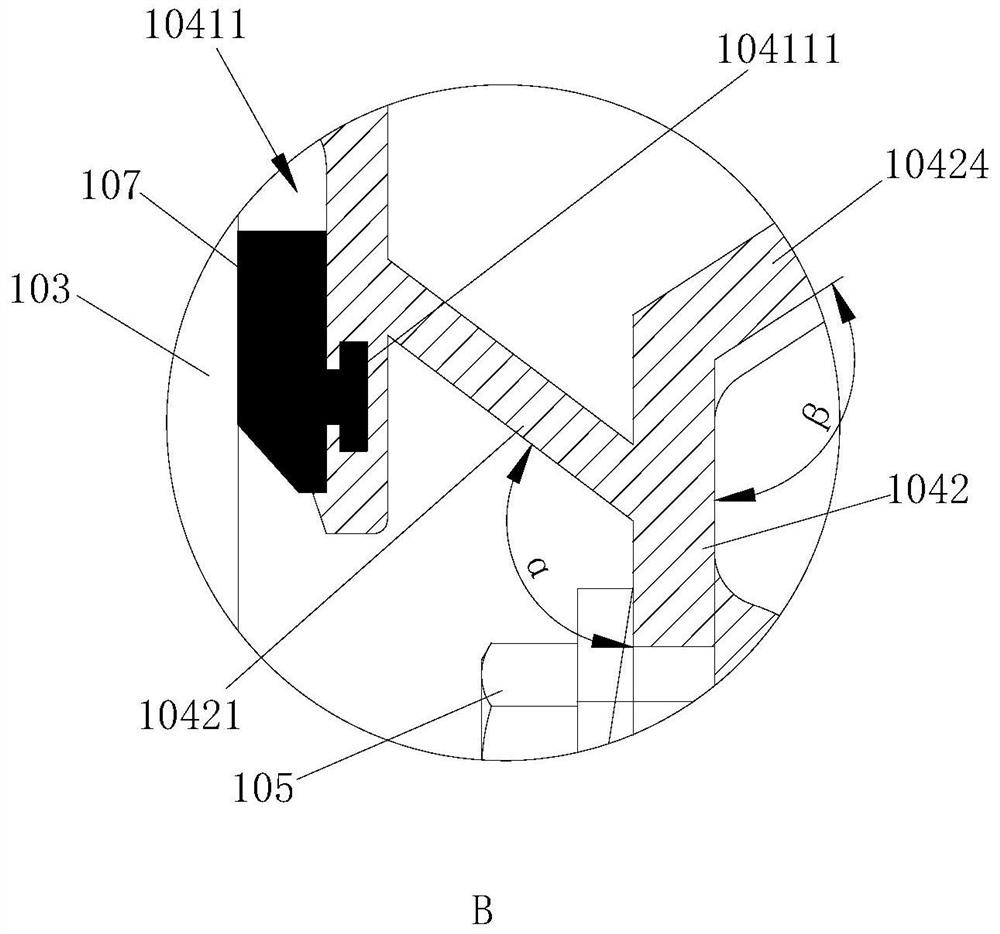

[0065] refer to figure 2 , image 3 , Figure 4 The building porcelain plate dry-hanging assembly 1 also includes an anti-loosening bolt 105 and a back bolt 106. The back bolt 106 is provided with a threaded connection hole 1061 along a direction perpendicular to its axis,...

Embodiment 2

[0077] refer to Figure 1 to Figure 8 , based on Embodiment 1, this embodiment discloses a dry-hanging structure of a building porcelain plate curtain wall, including a porcelain plate body 2 and the dry-hanging assembly disclosed in Embodiment 1, and the longitudinal keel 101 of the dry-hanging assembly is fixed on the building wall On the body 3, a first connection hole 201 is opened on the back of the porcelain plate body 2 along a direction perpendicular to the plate surface, and a second connection hole 202 communicating with the first connection hole 201 is opened on the side of the porcelain plate body 2, In this embodiment, the opening direction of the second connecting hole 202 is perpendicular to the opening direction of the first connecting hole 201 .

[0078] The back bolt 106 is connected in the second connection hole 202, and the back bolt 106 and the second connection hole 202 are tightly fitted. In other embodiments, the back bolt 106 can also be provided with ...

Embodiment 3

[0086] refer to Figure 1 to Figure 8 , the present embodiment discloses a construction method for a dry-hanging structure of a building porcelain plate curtain wall, which is used to construct and form the dry-hanging structure of a building porcelain plate curtain wall in the above embodiment, comprising the following steps:

[0087] S1: Material preparation

[0088] S1.1: Prepare dry-hanging components, process and weld longitudinal keels 101, horizontal beams 102 and right-angle corners 103 according to the size, and prepare connection components 1011 for connecting the longitudinal keels 101 to the building wall 3;

[0089] S1.2: Prepare the porcelain plate body 2, prepare the corresponding prefabricated mold, dry press the raw materials once to form a green body with a flat layer and prefabricated protrusions 203, and fire to form the required porcelain plate body 2 ;

[0090] The first connection hole 201 and the second connection hole 202 are processed on the boss ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com