A method for changing the polarity of the excitation bus bar of a generator

A technology of generators and busbars, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of generator rotor magnetization, uneven slip ring damage, and inability to perform rotor reversal work. To be simple, easy to operate, and maintain the overall aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

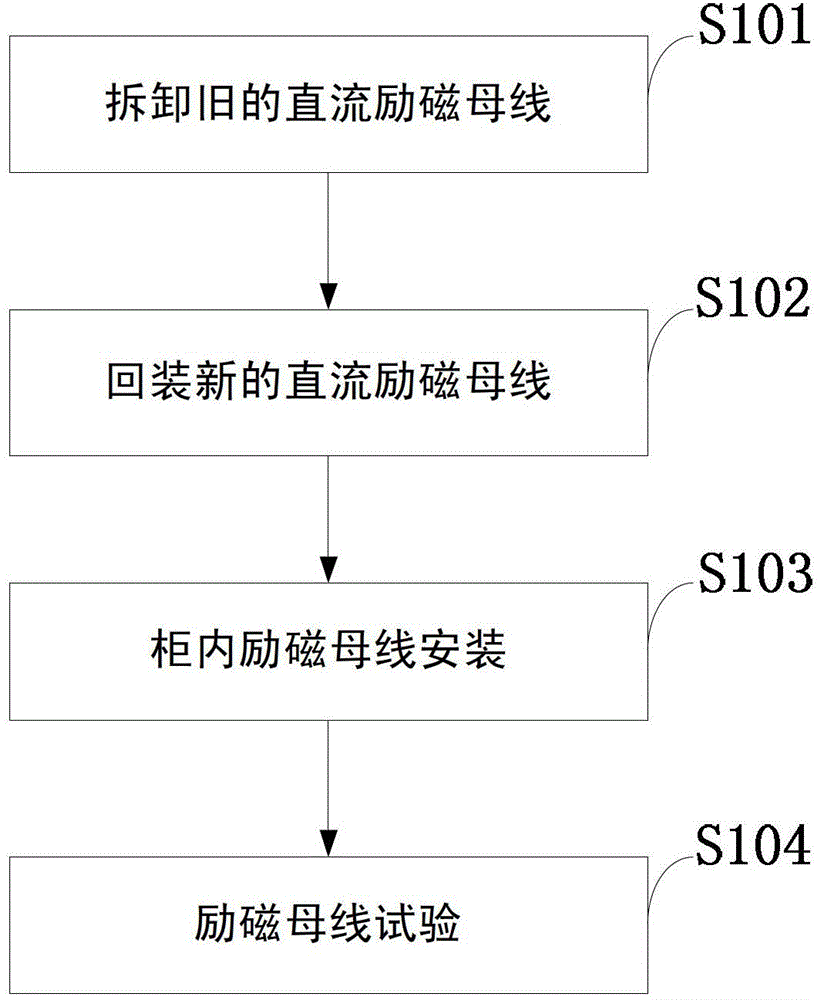

[0029] figure 1 A flow chart showing a method for changing the polarity of a generator excitation bus provided by the present invention includes the following steps:

[0030] S101 dismantling the old DC excitation busbar;

[0031] Reinstall the new DC excitation bus in S102;

[0032] Excitation busbar installation in S103 cabinet;

[0033] S104 Excitation bus test.

[0034] Wherein, said S101 dismantles the old DC excitation bus, which specifically includes the following steps:

[0035] Use tools to remove all the upper cover screws of the old DC excitation busbar, remove the insulating clips and busbar fixing screws i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com