Electrocar motor winding wire end twisting machine

A technology of motor winding and kinking machine, applied in the field of electric vehicle motor winding wire kinking machine and kinking machine, can solve the problems of kinking and other problems that are not suitable for electric vehicle motor winding wire ends, and achieves reduction of vibration and noise, good versatility, and high processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

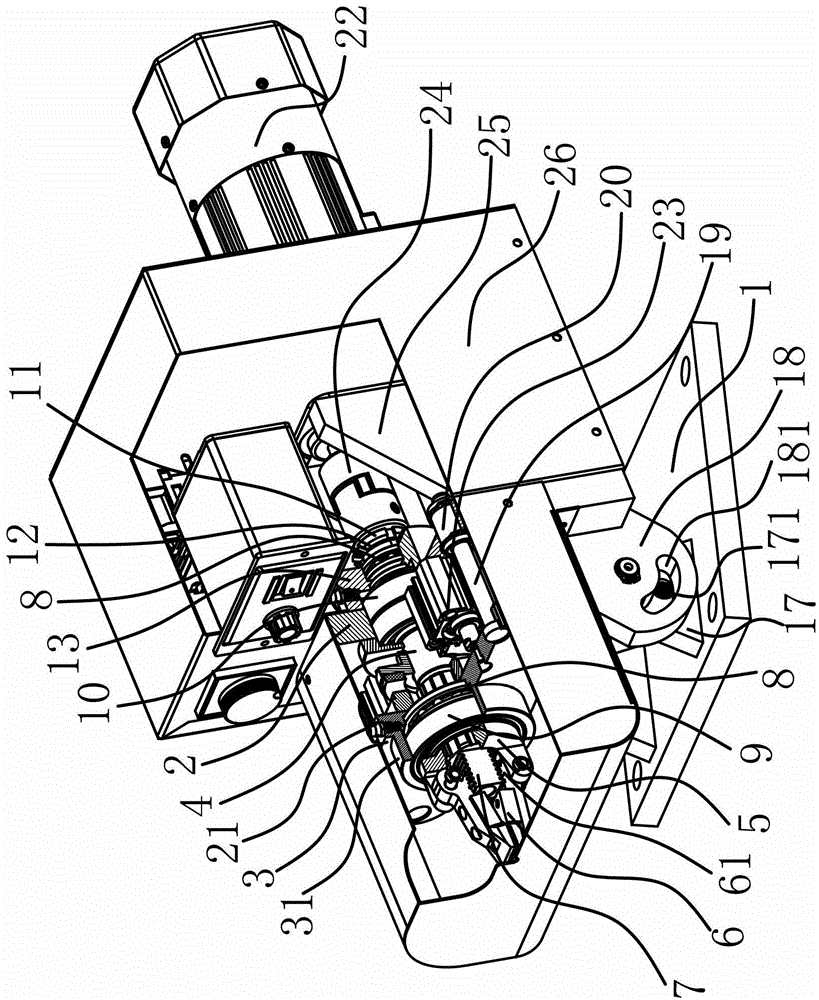

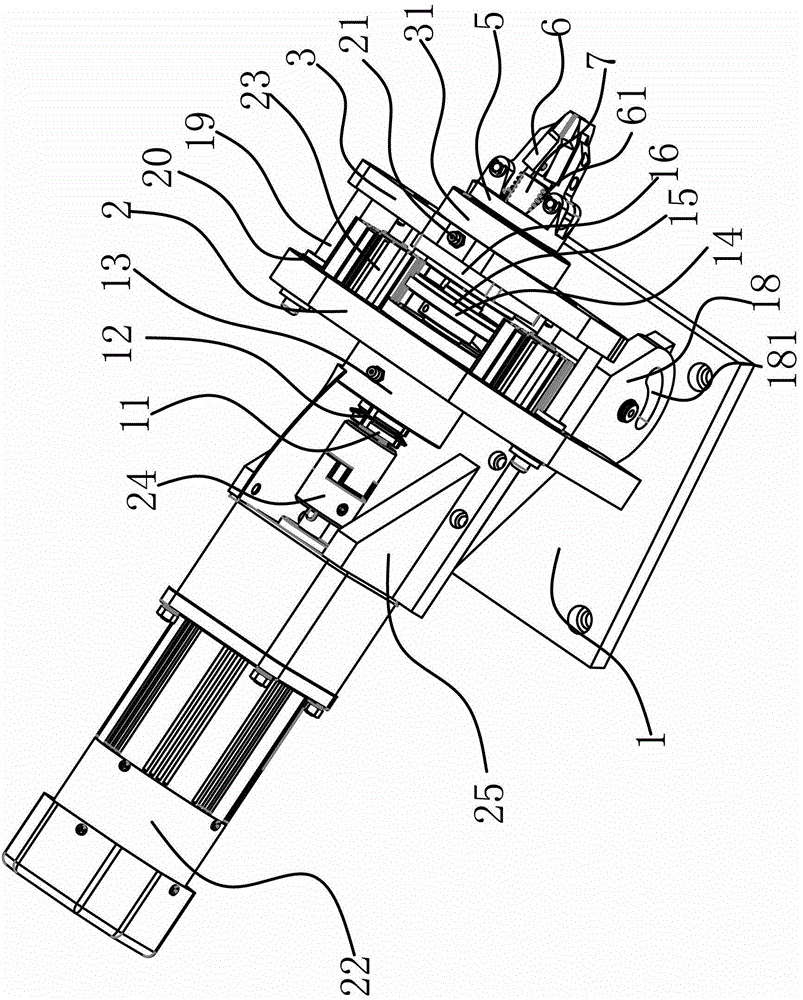

[0030] The electric vehicle motor winding wire head twisting machine includes a frame 1, a support plate 2, a push plate 3, a rotating main shaft 4, a clamp seat 5, a twisting clamp 6, a fixed bracket 25, a fixed seat 31, a drive motor 22, a drive cylinder 23, and a guide Mechanism, lubrication positioning structure, brake mechanism and angle adjustment mechanism.

[0031] Specifically, as figure 1 As shown, the support plate 2 is arranged on the frame 1, and the support plate 2 is also provided with a dust cover 26 for preventing external dust from entering the inside of the kink machine. The angle adjustment mechanism is arranged between the support plate 2 and the frame 1, and is used to change the angle formed by the support plate 2 and the frame 1, thereby adjusting the direction of the entire twisting machine. In this embodiment, the angle adjustment mechanism includes a hinge block one 17 fixed on the frame 1 and a hinge block two 18 fixed on the support plate 2, the h...

Embodiment 2

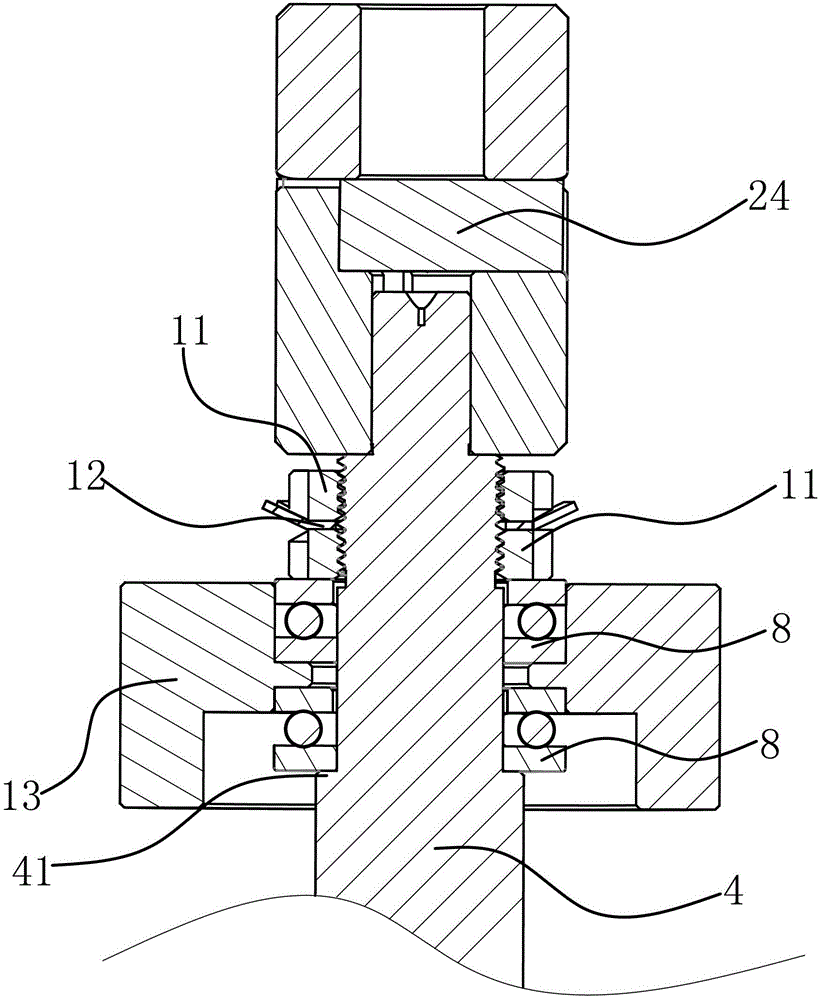

[0037] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the lubricating positioning structure includes a thrust ball bearing 8 and a round nut 11, and the rotating main shaft 4 has a shoulder 41, One end of the thrust ball shaft bears against the shaft shoulder 41 , and the other end is positioned by two round nuts 11 screwed on the rotating main shaft 4 , and a stop washer 12 is arranged between the round nuts 11 . The above installation method has a simple structure and is easy to implement.

Embodiment 3

[0039] The technical solution in this embodiment is basically the same as the technical solution in embodiment one or embodiment two, the difference is that in this embodiment, the brake mechanism includes a brake disc 14 fixed on the rotating main shaft 4, a push plate 3 A brake block 16 is provided at the position facing the brake disc 14, and the brake block 16 has a brake pad 15 corresponding to the position and shape of the brake disc 14, and when the push plate 3 is close to the support plate 2 The brake pads 15 are in contact with the brake disc 14 . Push plate 3 moves backward and in the process that kink pliers 6 are opened, brake block 16 is close to brake disc 14, and the brake disc 15 on the brake block 16 and brake disc 14 rub against each other to make rotating main shaft 4 decelerate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com