Non-volatile semiconductor storage device and method of manufacture thereof

A non-volatile, storage device technology, applied in the direction of semiconductor devices, electrical solid devices, electrical components, etc., can solve the problems of insufficient oxygen removal, insufficient molding process, and inability to perform stable resistance changes, etc., to achieve deviations in characteristics Small, high practical value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0056] First, the resistance variable nonvolatile semiconductor memory device in Embodiment 1 of the present invention will be described.

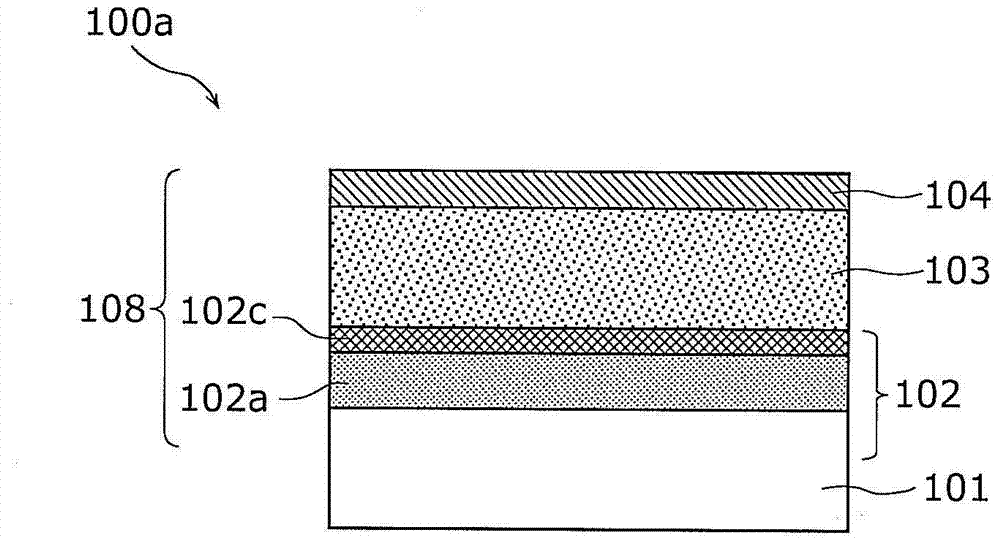

[0057] Figure 1A It is a cross-sectional view showing a configuration example of the variable resistance nonvolatile semiconductor memory device 100a according to the first embodiment of the present invention.

[0058] Such as Figure 1A As shown, the variable resistance nonvolatile semiconductor memory device 100a of the first embodiment includes: (1) a substrate 101; (2) a variable resistance element 108, which is composed of a lower electrode layer 102, an upper electrode layer 104, and The resistance variable layer 103 between these two electrodes is constituted.

[0059] The lower electrode layer 102 includes at least: (1) a first conductive layer 102a; (2) a second conductive layer 102c, which is formed on the first conductive layer 102a, and is a conductive layer in contact with the variable resistance layer 103 for making the lower part T...

Embodiment approach 2

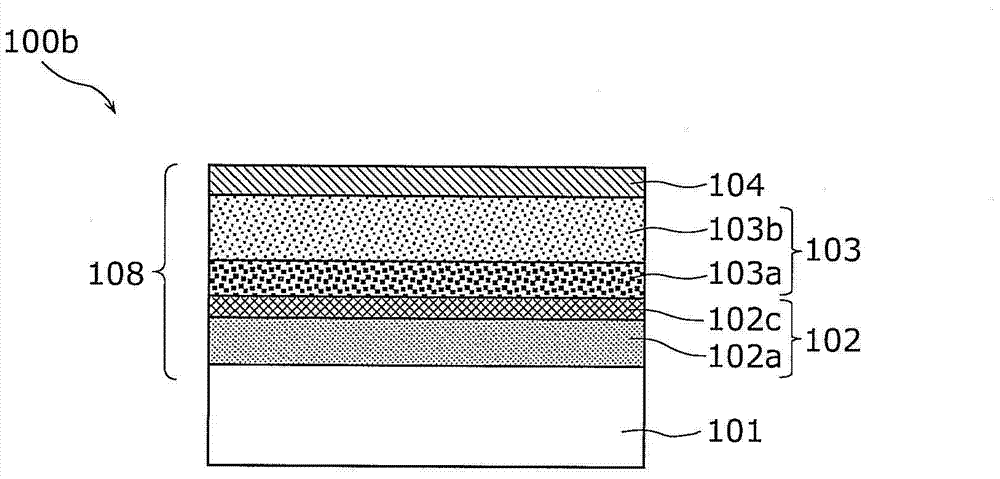

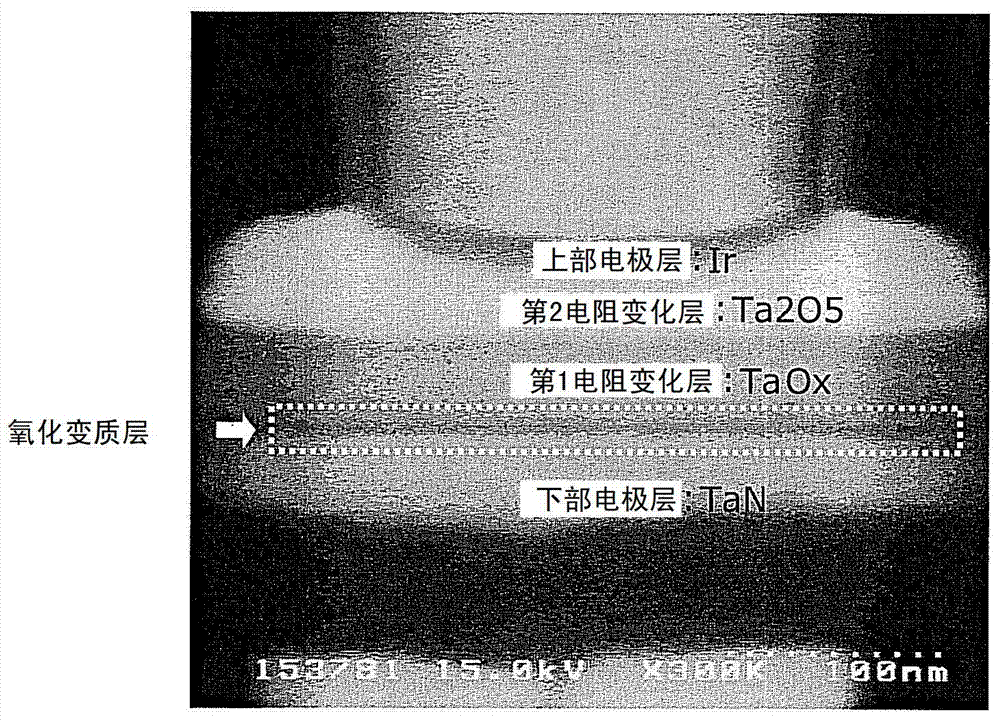

[0090] Next, a resistance variable nonvolatile semiconductor memory device in Embodiment 2 of the present invention will be described. In the first embodiment, the oxidative deterioration layer is not shown in the cross-sectional structure diagram of the nonvolatile semiconductor storage device, but in this embodiment, the oxidative deterioration layer is shown in the cross-sectional structure diagram of the nonvolatile semiconductor storage device. Layer and explain.

[0091] Figure 6A It is a cross-sectional view showing a configuration example of a variable resistance nonvolatile semiconductor memory device 200a according to Embodiment 2 of the present invention.

[0092] Such as Figure 6A As shown, the variable resistance nonvolatile semiconductor memory device 200a of the second embodiment includes: (1) a substrate 201; (2) a variable resistance element 208, which is composed of a lower electrode layer 202, an upper electrode layer 204, and The resistance variable layer 203...

Embodiment approach 3

[0105] Next, a resistance variable nonvolatile semiconductor memory device in Embodiment 3 of the present invention will be described. The non-volatile semiconductor memory device of the present embodiment has a structure in which a non-ohmic element is laminated on the variable resistance element in the first embodiment.

[0106] Figure 7A It is a cross-sectional view showing a configuration example of a variable resistance nonvolatile semiconductor memory device 300a according to Embodiment 3 of the present invention.

[0107] Such as Figure 7A As shown, the variable resistance nonvolatile semiconductor memory device 300a of the third embodiment includes: (1) a substrate 301; (2) a variable resistance element 308, which is composed of a lower electrode layer 302, an upper electrode layer 304, and The resistance variable layer 303 between these two electrodes is composed; (3) The non-ohmic element 309 is composed of the first electrode layer 305, the semiconductor layer 306, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com