Steering engine component

A technology of steering gear and components, which is applied in the field of screwless fast connection steering gear components, which can solve the problems of cumbersome screw connection, cumbersome process, and long time-consuming, etc., and achieve the effect of convenient and efficient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

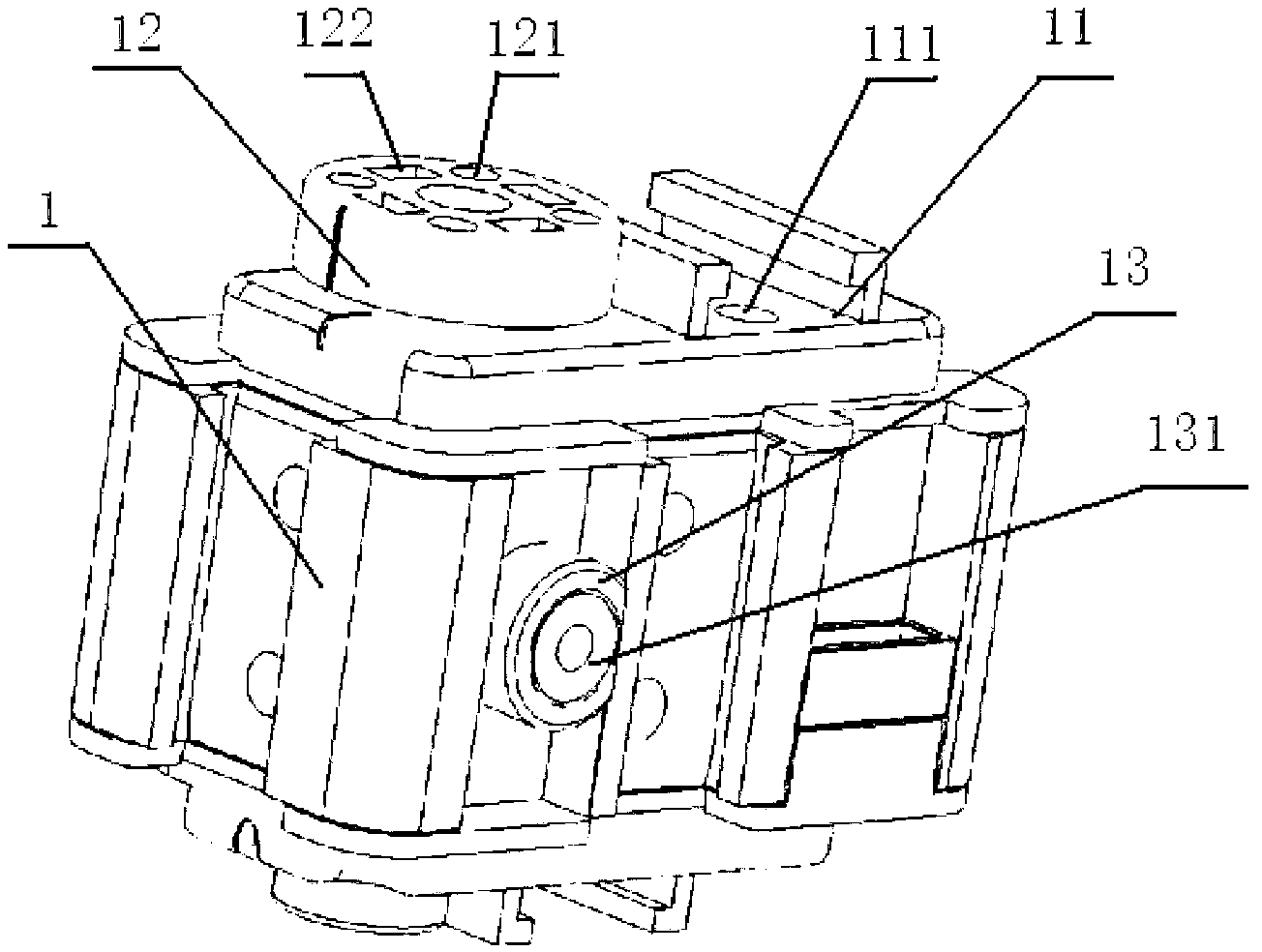

[0039] Such as figure 1 A preferred embodiment of the invention is shown. In this embodiment, the steering gear assembly includes a steering gear 1, at least one surface of the steering gear 1 is provided with an insertion slot 11 for plugging and fixing the steering gear 1 with an external structure, and the steering gear can be 1 Convenient plug-in fixation to external structural parts. In order to fix and insert the steering gear 1 more flexibly and conveniently, a slot 11 can be set on each surface of the steering gear 1, so that any slot 11 can be selected for plugging and fixing according to the characteristics of the external structural parts. The shape of the groove 11 is a half I-shaped, with a bottom surface and two "L"-shaped card edges, and at least one male buckle end 111 on the bottom surface, which is used to correspond to other steering gear components or external structural parts. The mating connection of the female buckle end of the male and female buckle e...

Embodiment 2

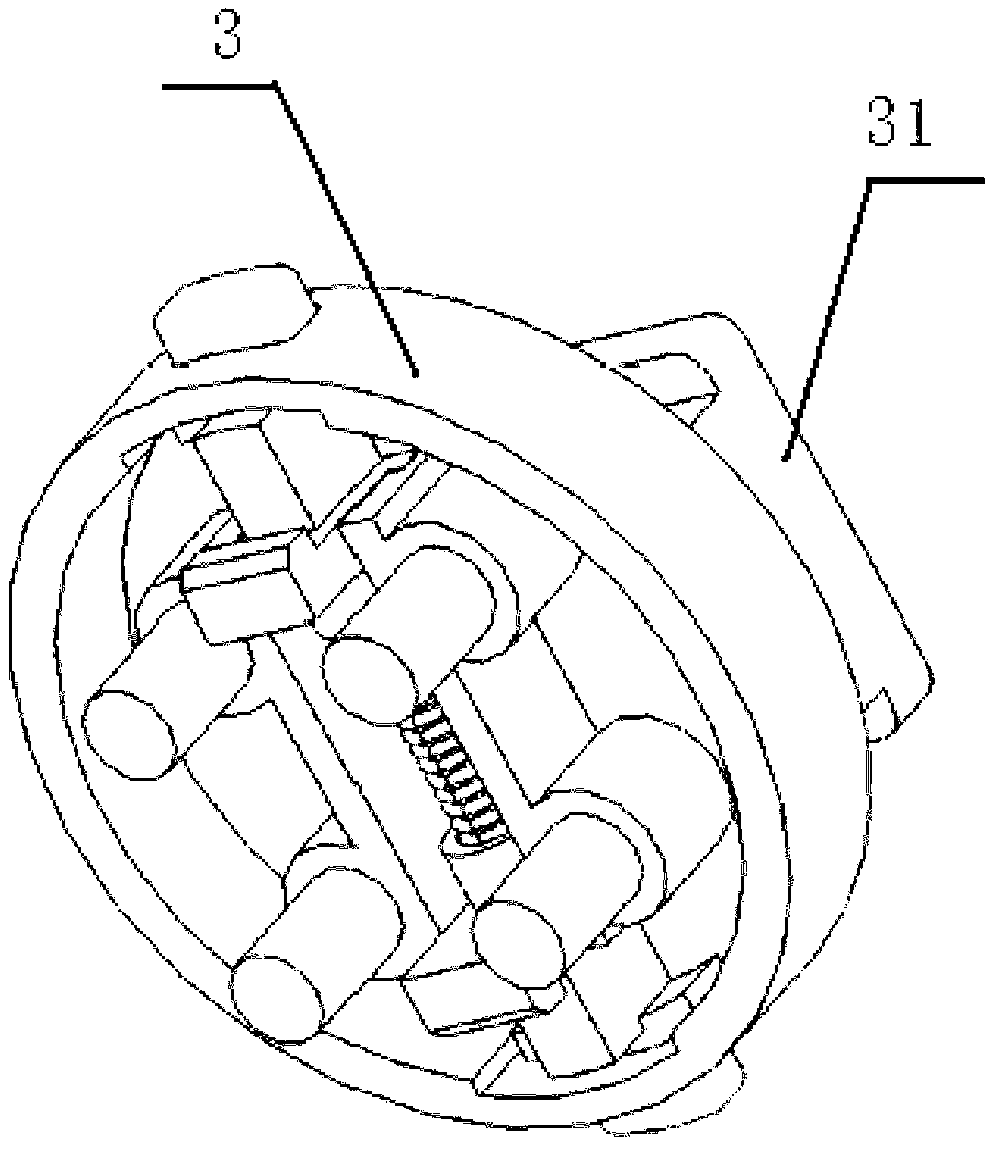

[0044] Combine below Figure 8 A preferred embodiment of the present invention applied to the quick connection of the single-ended output mode is illustrated, which is composed of a steering gear 1 and half of an I-shaped buckle cover 3 . As mentioned above, the bottom surface and the side structure of the half I-shaped buckle cover 3 are exactly the same as the buckle cover 2, so it can be fixedly connected with the steering gear output disk 12 in exactly the same way as the buckle cover 2. The half I-shaped block 31 on the upper surface of the half I-shaped buckle cover 3 can be fixedly connected with the external structure. Through the quick connection of the single-ended output mode, the rotational torque output by the steering gear 1 can be output to the external structural parts through the fixed connection between the steering gear output plate 12 and the half-shaped block 3. At the same time, the construction of this output mode is the simplest. Using a half I-shaped ...

Embodiment 3

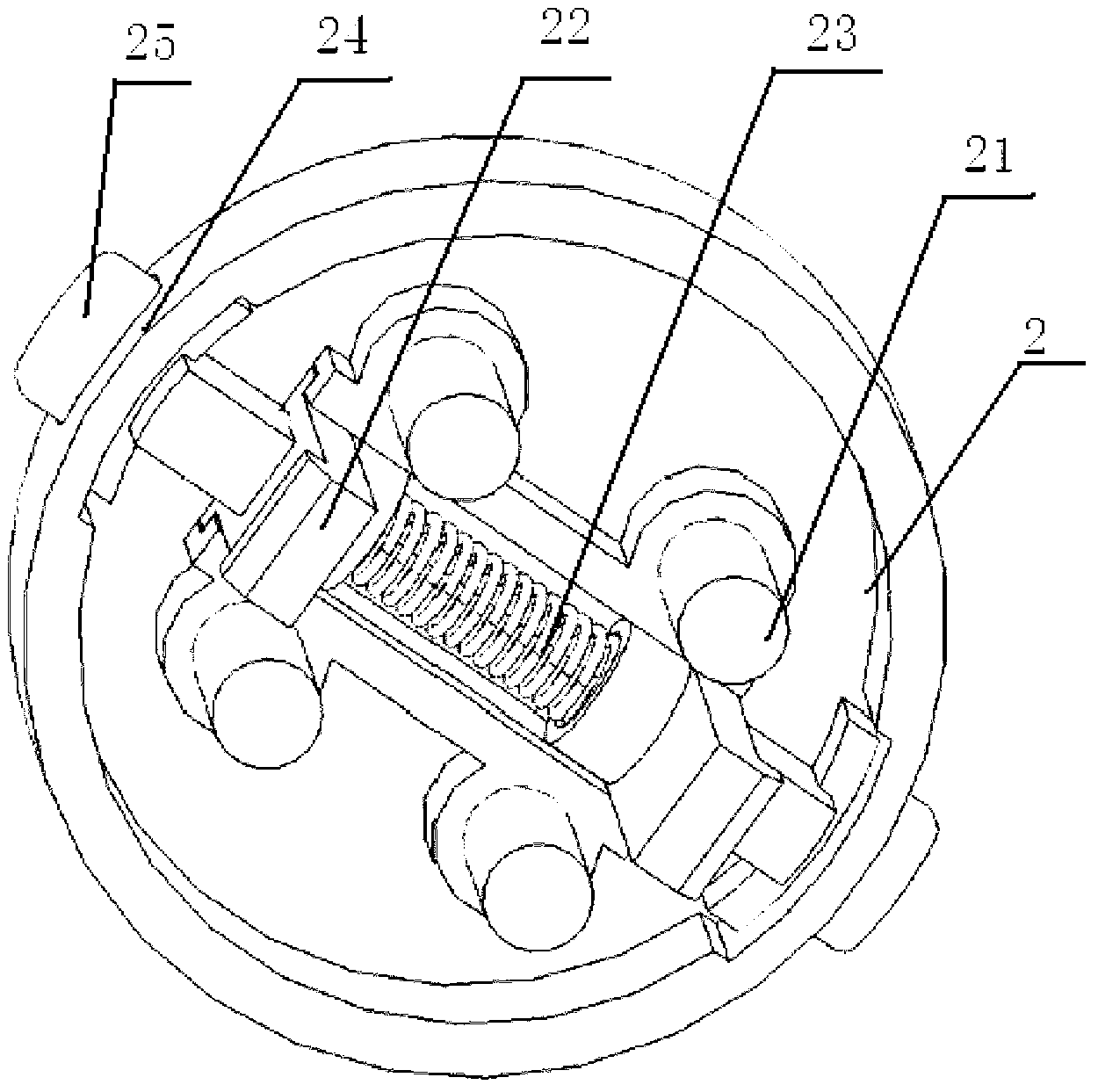

[0046] Combine below Figure 9 A preferred embodiment of the present invention applied to the quick connection of the dual-end output mode is illustrated, which consists of a steering gear 1 , a U-shaped piece 6 , a driven plate 4 and two buckle covers 2 . The driven disc 4 cooperates with the bearing 131 in the cylindrical boss 13 of the steering gear 1 through a cylindrical pin 43 in the center. Corresponding to the machine output disc 12, the two sides of the U-shaped part 6 are respectively aligned with the driven disc 4 and the steering gear output disc 12, so that the insertion pin 21 of the buckle cover 2 is inserted into the insertion hole 61 of the U-shaped part 6, And respectively penetrate the insertion hole 41 of the driven disk 4 and the insertion hole 121 of the steering gear output disk, the barb 22 of the buckle cover 2 passes through the buckle hole 62 of the U-shaped piece 6, hooks the driven disk 4 respectively The fastening groove 42 of the steering gear o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com